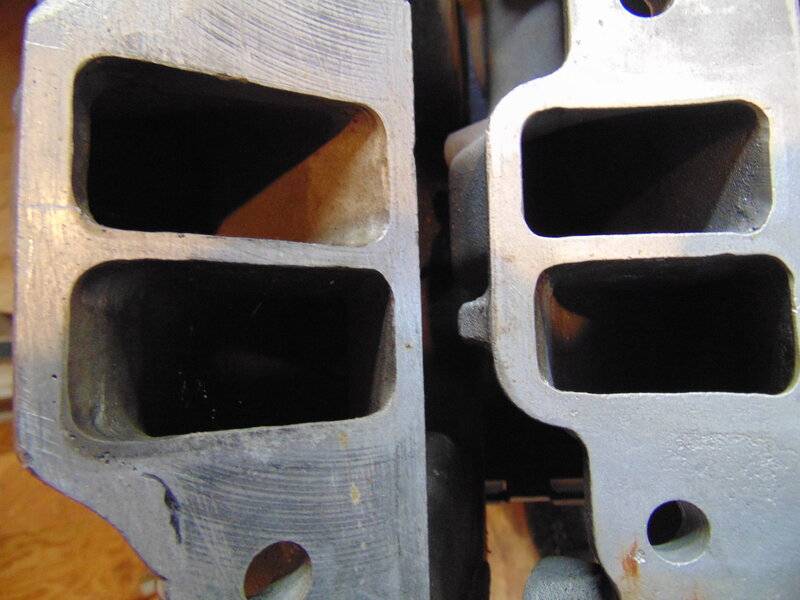

A couple days ago I was trying to reorganize a bunch of my parts hoard. I was moving intake manifolds around and noticed the difference between the ports on 2 manifolds. I was pretty sure they were both Edelbrock LD 4Bs made for the small port 273 and 318 heads, so I pulled them out and compared them. One was a relatively late one as indicated by the shape of the carb mount, the older one was a square bore mount with no extra plate required and had the Chrysler (Hustle Stuff?) part number cast into the manifold.

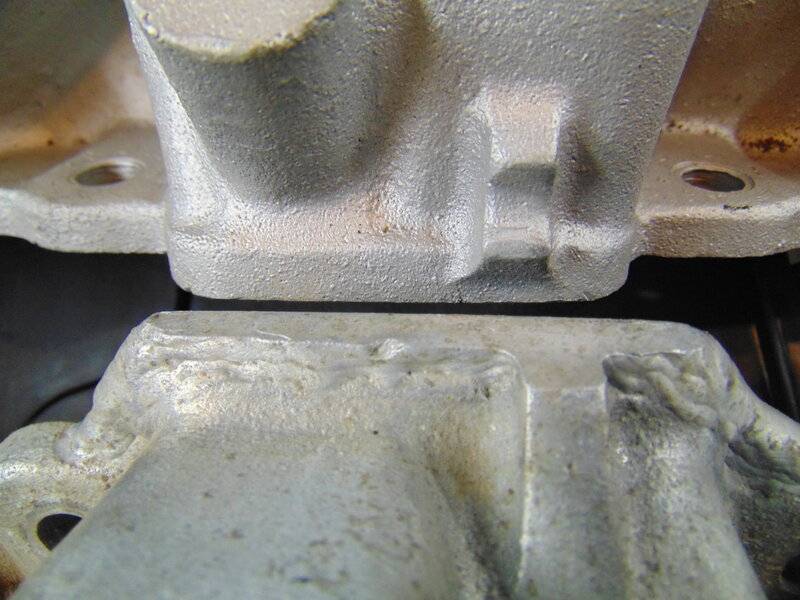

I remember getting the older one for a steal at a swap meet ($100) because the owner said that it had been repaired. I looked at the excellently executed welding and said what the heck and shelled out $100, took it home and put it on a shelf with another LD 4B. Once I started looking at the ports and measured them, the newer manifold had ports 2" tall (when you hear somebody talk about the good old days of quality control, look at the port alignment on that one) and the older manifold ports were 2 1/4 " tall. Further investigating showed that the welding was to build up the top of the mating surface and then opened up the ports to the size of a (you guessed it) a 340 port!

Whoever did this was a real artist converting a small port small block port to a large port configuration. It was a lot of work! So the question is, why? There has to be a story here...

Guess #1 - owner bought a 340 car early in the 68 model year and Edelbrock hadn't brought out the LD340 yet, so they made their own...

Guess #2 - owner had a 318 and wanted to install 340 or 360 heads and just modified the manifold they had to port match the new heads...

Guess #3 - owner was an old time hot rodder who just didn't think anything of using their skills and what was available rather than shell out $80 (what I paid for a new LD 4B in 1975)...

Whoever that guy was, my hat is off to them. That manifold has a feeling of real hot rodding history, now all I need is another 340 to try it out on...

I remember getting the older one for a steal at a swap meet ($100) because the owner said that it had been repaired. I looked at the excellently executed welding and said what the heck and shelled out $100, took it home and put it on a shelf with another LD 4B. Once I started looking at the ports and measured them, the newer manifold had ports 2" tall (when you hear somebody talk about the good old days of quality control, look at the port alignment on that one) and the older manifold ports were 2 1/4 " tall. Further investigating showed that the welding was to build up the top of the mating surface and then opened up the ports to the size of a (you guessed it) a 340 port!

Whoever did this was a real artist converting a small port small block port to a large port configuration. It was a lot of work! So the question is, why? There has to be a story here...

Guess #1 - owner bought a 340 car early in the 68 model year and Edelbrock hadn't brought out the LD340 yet, so they made their own...

Guess #2 - owner had a 318 and wanted to install 340 or 360 heads and just modified the manifold they had to port match the new heads...

Guess #3 - owner was an old time hot rodder who just didn't think anything of using their skills and what was available rather than shell out $80 (what I paid for a new LD 4B in 1975)...

Whoever that guy was, my hat is off to them. That manifold has a feeling of real hot rodding history, now all I need is another 340 to try it out on...