Lets review and discuss crimpers for 'type F' open barrel terminals.

For those not so familiar:

Open barrel is when the gripping portion starts open.

Pretty much all terminals in our cars are crimped to the wires with this design.

Type F open barrel terminals 'wings' get folded onto the wire so the reuslting cross section looks like an upside down W. The first pair grips the conductor and the second pair grips the insultator the same way. According to AMP catalogs, Type F may or may not have the insulation gripping wings.

Here's my impressions of three open barrel crippers I've bought, along with a typical (older) cheap closed barrel crimper as an occassional reference. One thing for sure, while sometimes they work the first try, to be consistant with different terminals and wire sizes, practice and some experimentation helps.

Astro Pneumatic 9477 with interchangable jaws:

This looked like it would do everything. At first everything was easy, other than figuring out which jaw positions should be used. More on that later. With one squeezer the conductor and insulator gets crimped neatly and to the same force.

The problem came with the male terminals that have stop tabs that stick out. The jaws are too wide to do these correct. One solution is to grind the side of jaws down.

About the jaws. They have mysterious numbers on them which are not the AWG sizes.

The booklet is what you'ld expect from an import item. It does have little chart which can sortof be used to figure out what position should be used for automotive wire. I took a pen and marked up the jaws and the box - which helps. With a narrower jaw, I could make a better decision visually.

It turns out the numbers cast into the jaws are metric wire sizes; either diameter or square area, I don't recall which. However I've found nothing is absolute in terms of deciding which size crimp is best. The various terminals have different thickness material and different length wings. So sometimes experimentation is required.

Bottom line is that these weren't the Do-all crimper I had hoped, but they have enough positive features that I don't regret the purchase. One bonus was when I needed to crimp some spark plug wires, instead of buying a crimper, I bought the optional jaws. Worked great for that.

Jaws will create both crimps of a female Chrysler type terminal in one squeeze

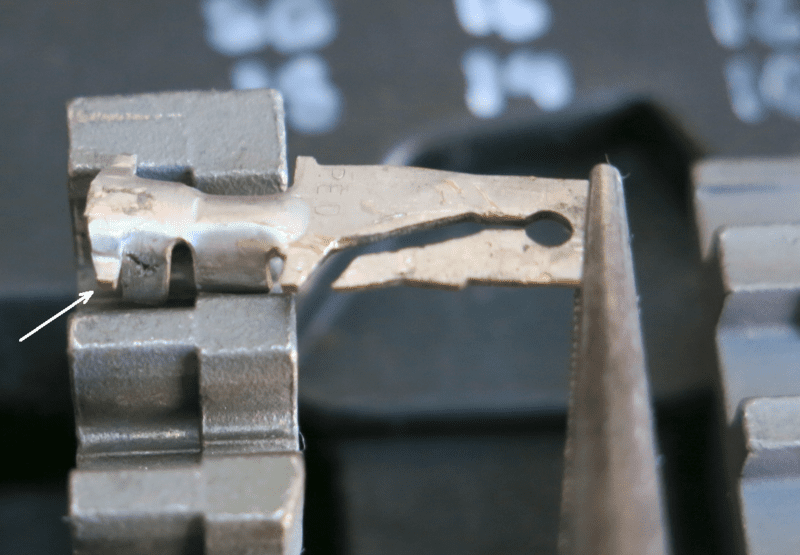

But a terminal with stop tabs like this male Packard 56 will get damaged.

For those not so familiar:

Open barrel is when the gripping portion starts open.

Pretty much all terminals in our cars are crimped to the wires with this design.

Type F open barrel terminals 'wings' get folded onto the wire so the reuslting cross section looks like an upside down W. The first pair grips the conductor and the second pair grips the insultator the same way. According to AMP catalogs, Type F may or may not have the insulation gripping wings.

Here's my impressions of three open barrel crippers I've bought, along with a typical (older) cheap closed barrel crimper as an occassional reference. One thing for sure, while sometimes they work the first try, to be consistant with different terminals and wire sizes, practice and some experimentation helps.

Astro Pneumatic 9477 with interchangable jaws:

This looked like it would do everything. At first everything was easy, other than figuring out which jaw positions should be used. More on that later. With one squeezer the conductor and insulator gets crimped neatly and to the same force.

The problem came with the male terminals that have stop tabs that stick out. The jaws are too wide to do these correct. One solution is to grind the side of jaws down.

About the jaws. They have mysterious numbers on them which are not the AWG sizes.

The booklet is what you'ld expect from an import item. It does have little chart which can sortof be used to figure out what position should be used for automotive wire. I took a pen and marked up the jaws and the box - which helps. With a narrower jaw, I could make a better decision visually.

It turns out the numbers cast into the jaws are metric wire sizes; either diameter or square area, I don't recall which. However I've found nothing is absolute in terms of deciding which size crimp is best. The various terminals have different thickness material and different length wings. So sometimes experimentation is required.

Bottom line is that these weren't the Do-all crimper I had hoped, but they have enough positive features that I don't regret the purchase. One bonus was when I needed to crimp some spark plug wires, instead of buying a crimper, I bought the optional jaws. Worked great for that.

Jaws will create both crimps of a female Chrysler type terminal in one squeeze

But a terminal with stop tabs like this male Packard 56 will get damaged.

Last edited: