I have a 440 conversion in a 71 Dodge Dart 450-500hp. I found it ran hotter than I would like so this past winter made some changes. Large tube Cold case radiator, new fan, new water pump, new temp gauge, shroud is perfectly fitted around the rad and sealed against the radiator. Car has a 180 degree thermostat. When the car is moving, the temp is locked at 180 and never moves. When idling in traffic at temperatures in the high( 80’s / 90’s) the car is good for 5-10min and starts to creep up and will surpass 200 in 15+ minutes or so. As soon as the car moves at any rate of speed it quickly corrects to 180. The new setup is a major improvement but falls just short of perfect. I know that 200 is nothing but the reality is that I know it will not recover until I get the car moving. Coldcase has a shroud / electric fan combo for the radiator that I am sure will correct the remaining issue at idle. I am not not sure if it will fit in the space between the radiator and water pump. If it does not fit, I plan to try an electric pusher fan in the front on a relay that will on turn on when the temp rises (at idle). It should be off when the car is traveling at a cooling speed. ……….. looking for feedback from my Mopar brothers and sister who have experience with this challenge. Cheers Ron D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mechanical fan + pusher fan question

- Thread starter RonsSwinger

- Start date

-

I know hot days up there are coming to an end. Try dropping the t stat down a bit. Try a 160 and see if that helps. I personally like 180 but run a copper rad with factory shroud and factory clutch fan with my 340 in the Demon with no issues at all.

Also, take the timing back a few degrees and see if that helps. My opinion only, but that is what we did before the fancy aluminum radiator explosion in the last 10 years. Lol!

Keep us posted on what works.

Syleng1

Also, take the timing back a few degrees and see if that helps. My opinion only, but that is what we did before the fancy aluminum radiator explosion in the last 10 years. Lol!

Keep us posted on what works.

Syleng1

Inertia

Well-Known Member

I would encourage you to review some of the "overheat" threads, I'm fairly sure that fan assembly made it to the "frisbee" across the backyard list .

Lotta bucks as I remember, didn't fly worth a chit either .

IIRC

Good luck .

Lotta bucks as I remember, didn't fly worth a chit either .

IIRC

Good luck .

following along

following alongSince the system raises above 180 at idle, a 160 deg thermostat will do nothing to stop that it will still go to 200.Try a 160 and see if that helps

If the system goes to 200 at idle and does not keep rising, stop worrying about it.

It will keep risingSince the system raises above 180 at idle, a 160 deg thermostat will do nothing to stop that it will still go to 200.

If the system goes to 200 at idle and does not keep rising, stop worrying about it.

dano

Evil Handy Man

Possibly too lean at idle. Add some fuel and see if it goes away. My dads 440 did this and advancing the timing 2 more degrees and increasing the idle fuel, it went away.

With that what is the static timing and carb.

With that what is the static timing and carb.

Yes, don't retard the timing. What pump did you use? Space, cast iron pump would save you 3/4", but then you'd have to change the radiator. Clutch fan? If you go electric fan, will need more from your alt, and wiring upgrade? No free lunch.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,918

- Reaction score

- 12,272

Here are a few tricks;

1) If you have an automatic transmission;

> you can run plenty of Idle-timing, so long as the engine stays out of detonation at stall. I mean the engine will like a lot. You can run as much as 25 or more degrees; until either of; the starter gives up, or until the engine develops a throttle Tip-in sag, due to insufficient Transfer-slot fuel.

>You probably should have a hi-capacity trans oilpan, with a lowered pick-up

> If you have a hi-stall, run an auxilliary cooler. and

> put the trans in Park during long idle times. This will dump all fluid pressure back to the pan, except the lube circuit, and reduce oil to the convertor, which will decrease the thrashing of the oil inside it.

2) run fresh cold air to the carb; hot air in, equals hotter air out.

3) Limit your water bypass system, or, make your heater core the bypass. Yes you'll get hot tootsies, but in a pinch it can be your back-up.

4) run an engine oil cooler, and/or a high capacity engine oilpan.

5) overdrive the fan

Just so you know, I once had an unsolvable overheat problem. I finally tore the engine down and

1) increased the Skirt clearance a tad, and

2) opened up the top ring gap a few thou; problem solved.

1) If you have an automatic transmission;

> you can run plenty of Idle-timing, so long as the engine stays out of detonation at stall. I mean the engine will like a lot. You can run as much as 25 or more degrees; until either of; the starter gives up, or until the engine develops a throttle Tip-in sag, due to insufficient Transfer-slot fuel.

>You probably should have a hi-capacity trans oilpan, with a lowered pick-up

> If you have a hi-stall, run an auxilliary cooler. and

> put the trans in Park during long idle times. This will dump all fluid pressure back to the pan, except the lube circuit, and reduce oil to the convertor, which will decrease the thrashing of the oil inside it.

2) run fresh cold air to the carb; hot air in, equals hotter air out.

3) Limit your water bypass system, or, make your heater core the bypass. Yes you'll get hot tootsies, but in a pinch it can be your back-up.

4) run an engine oil cooler, and/or a high capacity engine oilpan.

5) overdrive the fan

Just so you know, I once had an unsolvable overheat problem. I finally tore the engine down and

1) increased the Skirt clearance a tad, and

2) opened up the top ring gap a few thou; problem solved.

Most likely problem is water pump/fan turning too slowly; pump should be overdriven 10-20% by using a smaller pump pulley.

See here: www.stewartcomponents.com

If the cam is larger than stock, idle timing should be advanced [ NOT retarded ] & has a big influence on engine temp at idle, see below.

See here: www.stewartcomponents.com

If the cam is larger than stock, idle timing should be advanced [ NOT retarded ] & has a big influence on engine temp at idle, see below.

Great feedback. I have most of the list covered, except for the last paragraph……. breaking down the engine is past my skill set. “ overdrive the fan”…… explain…….. us a smaller pulley ………. Rev the engine at idle……… tks Ron DHere are a few tricks;

1) If you have an automatic transmission;

> you can run plenty of Idle-timing, so long as the engine stays out of detonation at stall. I mean the engine will like a lot. You can run as much as 25 or more degrees; until either of; the starter gives up, or until the engine develops a throttle Tip-in sag, due to insufficient Transfer-slot fuel.

>You probably should have a hi-capacity trans oilpan, with a lowered pick-up

> If you have a hi-stall, run an auxilliary cooler. and

> put the trans in Park during long idle times. This will dump all fluid pressure back to the pan, except the lube circuit, and reduce oil to the convertor, which will decrease the thrashing of the oil inside it.

2) run fresh cold air to the carb; hot air in, equals hotter air out.

3) Limit your water bypass system, or, make your heater core the bypass. Yes you'll get hot tootsies, but in a pinch it can be your back-up.

4) run an engine oil cooler, and/or a high capacity engine oilpan.

5) overdrive the fan

Just so you know, I once had an unsolvable overheat problem. I finally tore the engine down and

1) increased the Skirt clearance a tad, and

2) opened up the top ring gap a few thou; problem solved.

Timing is advanced. Looking into the pulley concept.Most likely problem is water pump/fan turning too slowly; pump should be overdriven 10-20% by using a smaller pump pulley.

See here: www.stewartcomponents.com

If the cam is larger than stock, idle timing should be advanced [ NOT retarded ] & has a big influence on engine temp at idle, see below.

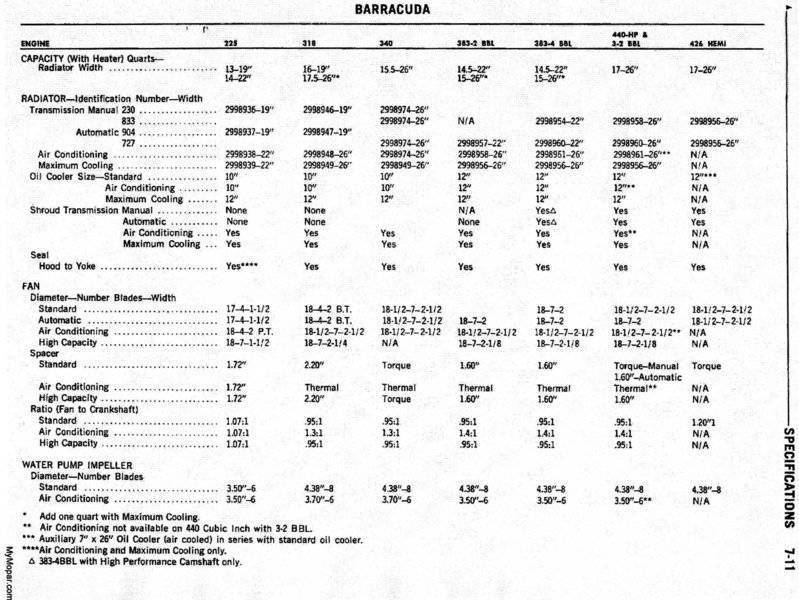

View attachment 1716146835

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,799

- Reaction score

- 3,575

Most likely problem is water pump/fan turning too slowly; pump should be overdriven 10-20% by using a smaller pump pulley.

See here: www.stewartcomponents.com

If the cam is larger than stock, idle timing should be advanced [ NOT retarded ] & has a big influence on engine temp at idle, see below.

View attachment 1716146835

I have seriously considered going with a programmable ignition for this very reason. I would love to run more timing at idle. I currently run 26/38, I forget which springs i'm using. I know it's all in by at least 2,500, because I like to have full timing at cruise RPM.

AMC Diplomat

Well-Known Member

You could try a heavy duty fan clutch if you haven't already

“ overdrive the fan”…… explain…….. us a smaller pulley ………. Rev the engine at idle

Yes and yes.

I got stuck in line at in -n-out in 90 deg weather.

The temp in my stock 273 2bbl (OEM copper brass HD cooling rad, fixed 7 blade fan, no shroud) started to climb, I'm not one to worry about the exact temp but the range. As it started to approach the higher end of of the factory scale I decided to add some RPM to see if I could get the temp down.

Low and behold I got it down to the normal driving range.

I don't have a tach but would assume 2000 rpm.

So 2 things came into play...

- The pump was circulating more fluid through the cooling system

- The fan was pulling more air through the radiator.

Assuming the OP has a clutch fan this might help and getting a more aggressive fan blade pitch might help too.You could try a heavy duty fan clutch if you haven't already

On a 96 Jeep GC, I thought the clutch was failing as temps rose more than I liked on a 95 deg day in a fast food line. ( I know, there is a team here) so I researched and found a aftermarket replacement for max cooling / A/C clutch. And after install the only difference I noted was the jet aircraft under the hood.

Probably why the factory reduced the number of blades on the over driven HD cooling water pumps.it will move water

Faster fan speed but slightly less pump output at the same engine rpm.

AMC Diplomat

Well-Known Member

Yes, the jet airplane sound can be annoying, but it's a cheap fix and beats throwing the parts cannon at the car in the hopes of making it run cooler.And after install the only difference I noted was the jet aircraft under the hood.

OP describes an issue that sounds like a lack of airflow at idle. If he's already tried a better fan clutch and fan, then he can try other things.

I like to do the simple things first. Usually works out ok.

Note that using a lower temperature thermostat does absolutely nothing to cool the engine in high ambient temperature conditions. All it does is open the thermostat earlier. After that it is up to the fan or road speed to keep the temperature under control.

Combustion is more efficient at higher engine temperatures. I always use a 195º thermostat. This keeps the engine temperature constant regardless of the exterior temperature (until it gets into the high 90s, at least), and provides effective cabin heat in the winter (which a 165º thermostat does not).

One problem with a pusher fan is that the fan motor and frame blocks airflow to the radiator, so it pretty much has to run constantly to compensate. It is also inherently much less efficient than a puller (compare the effect of blowing air through a piece of window screen, versus sucking it through). An engine-driven 7-blade clutch fan and a shroud would probably be more effective.

Combustion is more efficient at higher engine temperatures. I always use a 195º thermostat. This keeps the engine temperature constant regardless of the exterior temperature (until it gets into the high 90s, at least), and provides effective cabin heat in the winter (which a 165º thermostat does not).

One problem with a pusher fan is that the fan motor and frame blocks airflow to the radiator, so it pretty much has to run constantly to compensate. It is also inherently much less efficient than a puller (compare the effect of blowing air through a piece of window screen, versus sucking it through). An engine-driven 7-blade clutch fan and a shroud would probably be more effective.

Most of this has already been said, but let me reinforce some of it-

A lower thermostat will do NOTHING to address the issue you're having. It will just make the car run colder on the road, which isn't what you want anyway. It will still heat up at exactly the same rate at idle, so it will only extend your idle time by the time it takes to raise the temp 20°.

A pusher fan is 100% the wrong solution. You're addressing the symptom and not the cause, and adding all the wiring and amperage to run an electric fan properly is not inconsequential. And yeah, pushers are not as efficient, block air at speed, and shouldn't be necessary with a properly set up cooling system and fan.

A fan clutch SLOWS DOWN THE FAN. If you don't have one already, adding a clutch fan will not fix the problem at all, it might even make it worse. If you already have a clutch fan, try removing it and see if it fixes the issue. It could be allowing the fan to turn too slowly at idle if it's not working properly. If removing the clutch fan fixes the problem, time for a new clutch fan. If it doesn't, well, your clutch fan is fine and the issue is something else.

To fix this, you need to increase the airflow at idle. That is the problem, since you're running plenty cool when the airflow is good (at speed on the road). The most likely culprit is the water pump/fan pulley ratio, so, figure out what your pulley ratio is. Just measure the diameter of the crank pulley and the water pump pulley, it will tell you what you need to know. Factory ratio's were .95:1 for non-AC cars, they ran the HD water pump with 8 vanes. For AC cars the ratio was 1.4:1 for big blocks, with a standard 6 vane water pump...

You could have mismatched or aftermarket pulleys that are under-driving your fan/water pump too much, or even if you have the stock .95:1 pulley ratio you might not have the 8 vane pump, or maybe just need a higher ratio for your engine performance level/radiator/cooling system set up.

A lower thermostat will do NOTHING to address the issue you're having. It will just make the car run colder on the road, which isn't what you want anyway. It will still heat up at exactly the same rate at idle, so it will only extend your idle time by the time it takes to raise the temp 20°.

A pusher fan is 100% the wrong solution. You're addressing the symptom and not the cause, and adding all the wiring and amperage to run an electric fan properly is not inconsequential. And yeah, pushers are not as efficient, block air at speed, and shouldn't be necessary with a properly set up cooling system and fan.

A fan clutch SLOWS DOWN THE FAN. If you don't have one already, adding a clutch fan will not fix the problem at all, it might even make it worse. If you already have a clutch fan, try removing it and see if it fixes the issue. It could be allowing the fan to turn too slowly at idle if it's not working properly. If removing the clutch fan fixes the problem, time for a new clutch fan. If it doesn't, well, your clutch fan is fine and the issue is something else.

To fix this, you need to increase the airflow at idle. That is the problem, since you're running plenty cool when the airflow is good (at speed on the road). The most likely culprit is the water pump/fan pulley ratio, so, figure out what your pulley ratio is. Just measure the diameter of the crank pulley and the water pump pulley, it will tell you what you need to know. Factory ratio's were .95:1 for non-AC cars, they ran the HD water pump with 8 vanes. For AC cars the ratio was 1.4:1 for big blocks, with a standard 6 vane water pump...

You could have mismatched or aftermarket pulleys that are under-driving your fan/water pump too much, or even if you have the stock .95:1 pulley ratio you might not have the 8 vane pump, or maybe just need a higher ratio for your engine performance level/radiator/cooling system set up.

-