So after running an eBay Ready-to-Run Hei distributor for the past 5-6 years, I finally got around to putting a timing light on it and mapping out the advance curve. Come to find out, the curve was severely lacking! I ended up swapping out that distributor with a factory electronic distributor that I left the factory light spring in it and swapped out the heavy long looped spring with a black spring from the Fbo spring kit.

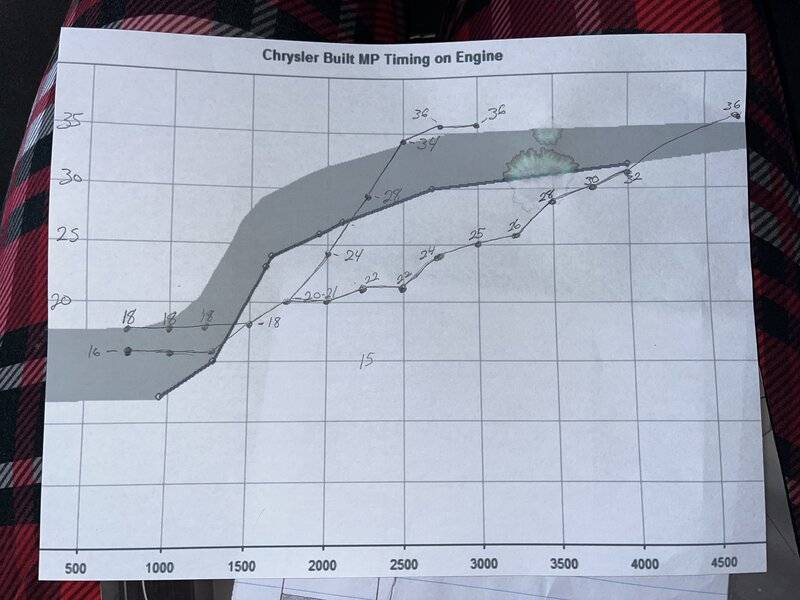

Here are the two curves laid over a graph that I saw @Mattax post on here a few times.

The R2R curve starts at 18 initial, overlaps the new distributors curve between 1500-1750, then goes to 20-21 at 2000rpm. The new curve is obviously much better but could still be improved. What step would y’all take next to optimize the curve some more?

Btw, this is on a bone stock 5.9 magnum running a China-gap intake and a 1405 carb and a manual transmission.

Here are the two curves laid over a graph that I saw @Mattax post on here a few times.

The R2R curve starts at 18 initial, overlaps the new distributors curve between 1500-1750, then goes to 20-21 at 2000rpm. The new curve is obviously much better but could still be improved. What step would y’all take next to optimize the curve some more?

Btw, this is on a bone stock 5.9 magnum running a China-gap intake and a 1405 carb and a manual transmission.