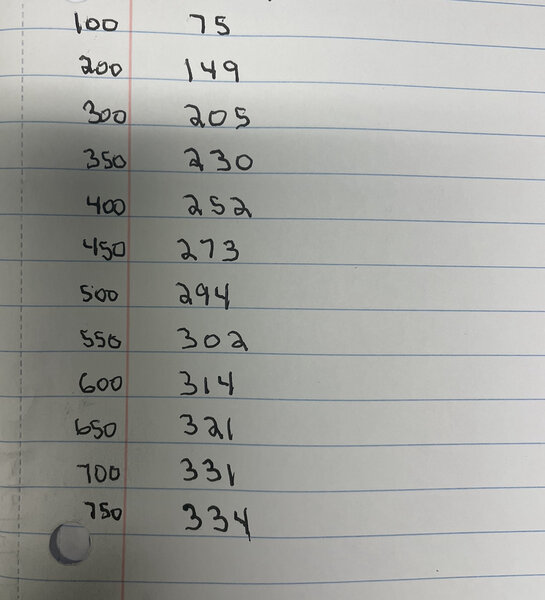

At least for me. I’m working on a set of 2.08 valve Edelbrock heads for a friend which I never do. Just to much work making this size valve work. But he’s a good friend. 1/2 way through my porting work I asked my son to ask him what size head gasket was he running. I about croaked when he said 4.060. Well honestly I wouldn’t have gone with this valve size knowing that. Now they found out they have to bore the block so he’s jumping to a 4.080 gasket. Still not enough to do what I want and need to do. I was so pissed off after three flow tests of jumpy azz Airwolf type numbers I turned off the shop lights and took a 2.5 day vacation. Today I dug my set of 2.08 valve Edelbrock heads for my car that I haven’t touched in 8 months and took some measurements. The last flow test maxed out at 228cfm but I thought there was more left. So after I measured them I tried a couple things I’ve been thinking about and threw them on the bench. Pretty dog gone pleased but I may quickly try one more thing before I jump back on Vic’s heads and hopefully get me the 318-322cfm or as close to it as I can get him. Here’s where I’m at on mine. These are stock location pushrods

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New best flow numbers for Edelbrock heads

- Thread starter pittsburghracer

- Start date

-

very nice !

Impressive. Am I correct when I say I see the pushrod holes have been tubed? Either way, nice work!

Impressive. Am I correct when I say I see the pushrod holes have been tubed? Either way, nice work!

Every Edelbrock type of head that I work on is tubed by me before I port it. Be it a 290 cfm 2.02 valve or a 2.08 valve I need that area.

U SIR - are making some EDELBROCK guys happy who were thinking of future porting etc !!!

U SIR - are making some EDELBROCK guys happy who were thinking of future porting etc !!!

Trouble is I can’t offer these numbers but I’m trying to hopefully find some 318-322 type of numbers At hopefully only a 200.00 upgrade from the 2.055. Those customers have to be willing to run number close to the 1008 bore size gasket (4.160-4.180) that bigger valve needs breathing room.

Danny Bellmore

Active Member

Very nice work John!

Great info to say the least !!Trouble is I can’t offer these numbers but I’m trying to hopefully find some 318-322 type of numbers At hopefully only a 200.00 upgrade from the 2.055. Those customers have to be willing to run number close to the 1008 bore size gasket (4.160-4.180) that bigger valve needs breathing room.

Those u did with 2.05s will satisfy my goals and much appreciated on all your effort with them.

1bad360duster

Well-Known Member

- Joined

- Dec 2, 2009

- Messages

- 314

- Reaction score

- 167

Why does the gasket size matter so much if the bore is only say 4.03-.04? I’ve seen this on other heads too

Why does the gasket size matter so much if the bore is only say 4.03-.04? I’ve seen this on other heads too

Trust me it just does. The air has to get out past the chamber wall. You can even see this flowing a stock Speedmaster head and a stock Edelbrock head. The Speedmaster chamber is much nicer around the intake valve.

Just Send It

There goes the neighborhood!

Impressive

Hell yeah! Nice work my friend!

Impressive

Hell yeah! Nice work my friend!

That other set sure had me pissed off over the weekend. Pretty sure I have a plan that will

Work after taking some measurements. I wish I had the set off my engine in my duster to double check something.

I'm just patiently waiting to hear what you decide to do on my next set of heads..... lolThat other set sure had me pissed off over the weekend. Pretty sure I have a plan that will

Work after taking some measurements. I wish I had the set off my engine in my duster to double check something.

-