REALLY good!!Looking good Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Next Phase of my Mopar Life

- Thread starter BrianT

- Start date

-

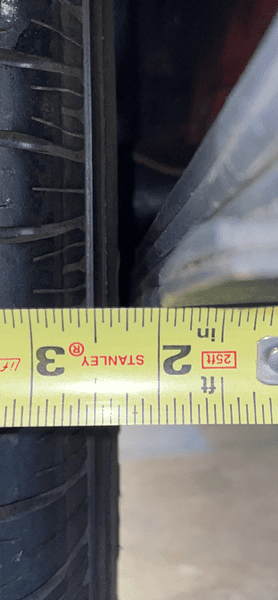

The reason I installed the 1/2" offset kit was because I only had 5/16" clearance between the springs and my rear tires.

I threw a tape measure on it today, and now I have 1 5/16" clearance?!?!

I had completely forgotten that the 8.25 rear end was one inch narrower than the 8.75. I gained 1/2" clearance from using the new rear end and another 1/2" from the offset spring kit, for a total gain of 1". It also pushed the rear tires out and that's what caught my eye and got me thinking. It's amazing that the human eye can perceive a 1/2" difference and the brain can recognize the change.

I threw a tape measure on it today, and now I have 1 5/16" clearance?!?!

I had completely forgotten that the 8.25 rear end was one inch narrower than the 8.75. I gained 1/2" clearance from using the new rear end and another 1/2" from the offset spring kit, for a total gain of 1". It also pushed the rear tires out and that's what caught my eye and got me thinking. It's amazing that the human eye can perceive a 1/2" difference and the brain can recognize the change.

Time for bigger tires!!!

I plan on keeping these as my "street" tires. They are basically brand new and will be fine driving around this summer. When I go to my "strip" set up, I'll stuff the biggest sticky tire in there that I can.

I was standing around yesterday admiring my work from the previous day and I remembered that I had the trunk light harness off of my old Dart. I don't know why I kept it, but it was one of the small things that I had added and I wanted to have it. Fifteen minutes later it was installed on the Duster.

I just finished my new trunk molding and I was wondering what that flange was for. Now I know, thanks!

Happy Easter everyone! Got a busy weekend so not much getting done to the car, but I did manage to buy and assemble a HF transmission jack. I have been looking for a used one for a while now, but always seem to just miss out on them. I'll use this one once, and then probably list it for sale.

@VOETOM came over this morning and we were able to measure the run out on the bellhousing. It has .032 total run out, divided by two gets us .016. I ordered a set of .014 offset dowels from RobbMcPerformance Bellhousing Alignment Dowels to get the bellhousing back to within specs.

While we were under there Tom muscled the transmission into place so that we could take measurements for the driveshaft I am having built. We knew what length a V8 4 speed with an 8 3/4" should take, but my OCD wouldn't let me have a driveshaft built that might not fit. The measurements came right in at stock specs. I'll swing by the drive train shop next week and get them started on it.

While we were under there Tom muscled the transmission into place so that we could take measurements for the driveshaft I am having built. We knew what length a V8 4 speed with an 8 3/4" should take, but my OCD wouldn't let me have a driveshaft built that might not fit. The measurements came right in at stock specs. I'll swing by the drive train shop next week and get them started on it.

Tom is a great guy. He helped me out big time with the exhaust on my Barracuda!

Measure twice, cut once!

I picked up my driveshaft Friday after work. It's a 3 1/2 inch with 1350 joints built at a local driveline shop. It should stand up to anything that I throw at it.

More progress was made last weekend. VoeTom came over and we installed the offset dowels for the bellhousing. Total run out is now within specs. I replaced the pilot bushing and installed the flywheel, clutch and pressure plate.

We had the spark plugs out to make it easier to rotate, and I noticed that one of them had a cracked porcelain. Luckily I had a set of brand new NGKs on the shelf gathering dust, so I put them in. We had to remove the oil filter adapter to pound out the old dowels so it went back in with all new gaskets and a fresh Wix oil filter.

We had the spark plugs out to make it easier to rotate, and I noticed that one of them had a cracked porcelain. Luckily I had a set of brand new NGKs on the shelf gathering dust, so I put them in. We had to remove the oil filter adapter to pound out the old dowels so it went back in with all new gaskets and a fresh Wix oil filter.

While the project has hit several set backs along the way, I am happy to report that the 18 spline 4 speed is installed and shifting well! @VOETOM has been very helpful along the way and the car wouldn't be running/driving without his help. He was able to borrow a tool made from an 18 spline input shaft which solved our problems. I owe Tom a huge debt of gratitude for his help and friendship.

The problem we were having seems to have come from the crappy plastic alignment tool that McLeod supplies with their clutch kits. We would have the dual discs lined up perfectly (or so we thought), but when we tried to install the trans, it just wouldn't go. So the whole QT bell would have to come off along with its 20 or so bolts and nuts. Then we would look at it, scratch our heads and check alignment on the discs AGAIN. It got to be very frustrating and emotionally draining. I would get so excited that this would be the day that I would get to drive my car again after many months, only to have my dreams crushed when it wouldn't go back together. At least three times this summer I had to take a few weeks off and clear my head and emotions before I was ready to start on it again.

We finished it just in time to get some fall cruising in and maybe a couple of car shows. I'm taking it to the local pizza joint tonight for their monthly car show. First time I've been able to attend this year!

The problem we were having seems to have come from the crappy plastic alignment tool that McLeod supplies with their clutch kits. We would have the dual discs lined up perfectly (or so we thought), but when we tried to install the trans, it just wouldn't go. So the whole QT bell would have to come off along with its 20 or so bolts and nuts. Then we would look at it, scratch our heads and check alignment on the discs AGAIN. It got to be very frustrating and emotionally draining. I would get so excited that this would be the day that I would get to drive my car again after many months, only to have my dreams crushed when it wouldn't go back together. At least three times this summer I had to take a few weeks off and clear my head and emotions before I was ready to start on it again.

We finished it just in time to get some fall cruising in and maybe a couple of car shows. I'm taking it to the local pizza joint tonight for their monthly car show. First time I've been able to attend this year!

Dartswinger70

Well-Known Member

18 Spline, that's the hemi spline right?

Glad to here you finally got it sorted out Brian. Tom is a great guy. We always used to use broken input shafts for alignment tools, because we didn't have anything else.

Inland truck up by WoF did the driveshaft. Brian Haflinger is doing my engine.You're doing good work as always, Brian!

Who is handling your engine machine work and driveshaft? Some of us locals need to know!

Last edited:

I was actually able to take the car to it's first car show/cruise in of the season (at least for me!). I'm still on what I consider shake down runs. Listening to every pop, groan, rattle etc. I'm supposed to take it easy for the first 500 miles while breaking in the clutch discs and also the rear gears, so that's what I'm doing. The new shifter works slick as can be and shifts are firm and positive. Mileage was 132,200 when the changes were made. Gonna see how many miles I can rack up before putting it away for the winter.

I noticed a small puddle of oil under it last night. I think I may have damaged the T adapter that allows me to run an idiot light and also a mechanical gauge. I'll pull it apart and see if I can see any damage. I may just remove the adapter and run an oil gauge only. The motor is rebuilt and solid. I shouldn't need to constantly monitor oil pressure with an 'idiot' light.

Here's a pic from last night. The weather was absolutely gorgeous for a show and I even won a pizza from my favorite pizza joint who hosts the monthly event.

I noticed a small puddle of oil under it last night. I think I may have damaged the T adapter that allows me to run an idiot light and also a mechanical gauge. I'll pull it apart and see if I can see any damage. I may just remove the adapter and run an oil gauge only. The motor is rebuilt and solid. I shouldn't need to constantly monitor oil pressure with an 'idiot' light.

Here's a pic from last night. The weather was absolutely gorgeous for a show and I even won a pizza from my favorite pizza joint who hosts the monthly event.

FlamesAreWicked

Well-Known Member

Great looking car with some nice upgrades!

4spdragtop

Well-Known Member

Beautiful! Free pizza is the best!

Gorgeous car!! I likewise struggled with an angled T adapter as I run both in the avatar so I can relate.

Last edited:

mygasser

Well-Known Member

by the time an idiot light comes on it's usually too late for the crank bearings anyway so.....

neil.

neil.

Looks great!

hcallaway

Well-Known Member

Truly a beautiful car. You have put a lot of effort to get it to this point!

I mentioned it above but haven't really talked about it, @Brian Hafliger is building me a W2 headed 416 engine for my Duster. I talked to him last night and things are progressing nicely so I thought I could officially let the cat out of the bag.

This time last year, I found a 340 block that I found localish to me. It was a standard bore block with no visible damage, and the seller agreed to take it to his machine shop for them to check it out before I bought it. I spoke to his machine shop guy and Brian later confirmed, that it is a good block and would be a good candidate for a rebuild. So, I strapped it onto a pallet and shipped it out to IMM.

The block is now ready for it's final cleaning and Brian says he should be ready to start assembling the short block soon. There was a short delay while the block was sent out to get the lifter bores bushed, but the block is back now and we are moving forward. We will be using a Molnar crank and rods, with Icon full dish pistons. Brian has been working on the heads doing a little port clean up and will gasket match the intake. We will be running Jesel 1.7 rockers. He said they should flow in the 310-315 range. Intake is a NOS Mopar P4452891 single plane that even came with gaskets and instructions.

Brian spoke with Jim at Racer Brown and is having a custom solid roller camshaft ground for it. Specs are 258@.050 and .690 lift. This is going to be a mostly street driven car with an occasional trip to the track, and Jim picked a grind that takes that into consideration. We will be running BAM solid rollers and custom push rods.

Headers will be TTI 1 7/8" with a full 3" exhaust with custom mufflers from my old Dart that @VOETOM built for me.

This is about all of the info I got from Brian on this update. I was scribbling notes as fast as I could while he was telling me about the build. I can't answer many specific technical questions. I trust Brian and that's why I chose him to build my engine. His reputation proceeds him and if he says something needs to be done, or if he suggests a specific part I'm going to believe him and go with it. He said he should be able to start sending me pictures as the build progresses and I will keep the thread updated.

This time last year, I found a 340 block that I found localish to me. It was a standard bore block with no visible damage, and the seller agreed to take it to his machine shop for them to check it out before I bought it. I spoke to his machine shop guy and Brian later confirmed, that it is a good block and would be a good candidate for a rebuild. So, I strapped it onto a pallet and shipped it out to IMM.

The block is now ready for it's final cleaning and Brian says he should be ready to start assembling the short block soon. There was a short delay while the block was sent out to get the lifter bores bushed, but the block is back now and we are moving forward. We will be using a Molnar crank and rods, with Icon full dish pistons. Brian has been working on the heads doing a little port clean up and will gasket match the intake. We will be running Jesel 1.7 rockers. He said they should flow in the 310-315 range. Intake is a NOS Mopar P4452891 single plane that even came with gaskets and instructions.

Brian spoke with Jim at Racer Brown and is having a custom solid roller camshaft ground for it. Specs are 258@.050 and .690 lift. This is going to be a mostly street driven car with an occasional trip to the track, and Jim picked a grind that takes that into consideration. We will be running BAM solid rollers and custom push rods.

Headers will be TTI 1 7/8" with a full 3" exhaust with custom mufflers from my old Dart that @VOETOM built for me.

This is about all of the info I got from Brian on this update. I was scribbling notes as fast as I could while he was telling me about the build. I can't answer many specific technical questions. I trust Brian and that's why I chose him to build my engine. His reputation proceeds him and if he says something needs to be done, or if he suggests a specific part I'm going to believe him and go with it. He said he should be able to start sending me pictures as the build progresses and I will keep the thread updated.

Last edited:

-

Similar threads

- Replies

- 11

- Views

- 467