Sedanman

67-9 Valiant specialist

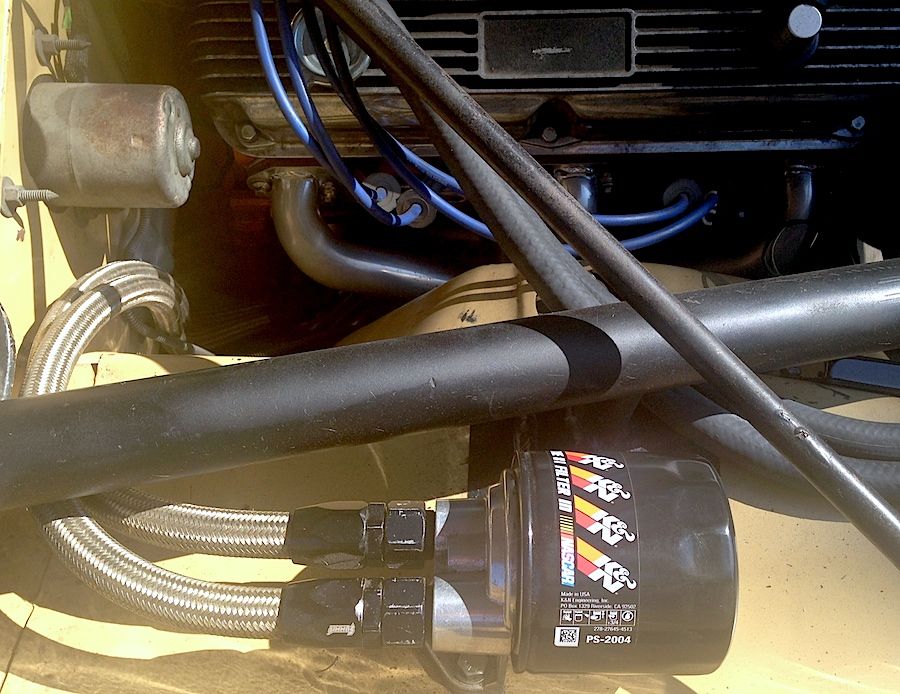

It was a PITA but this is what I had to do to make it work. Give some input/ideas if I went the right way. The first 3 pics are of what I had to work with and the rest are of the mods I had to make to make it work.

The filter is about 6 inches above the headers

You might want to reconsider using all those 90's. IMO they'll restrict oil flow quite a bit. I'd also drill 4 more holes in the stock oil filter plate

You can always use what the orig owner of dads cuda installed. This was in with a bunch of receipts Ive been going thru LOL

Fishy,let's see your filter set up. I see your block plate is the same and you have 90's. How does it work on your motor?

I changed the toilet paper in one of those when I worked in a lube shop. It was on a dodge diesel. Only time I ever saw it.