Mattax

Just the facts, ma'am

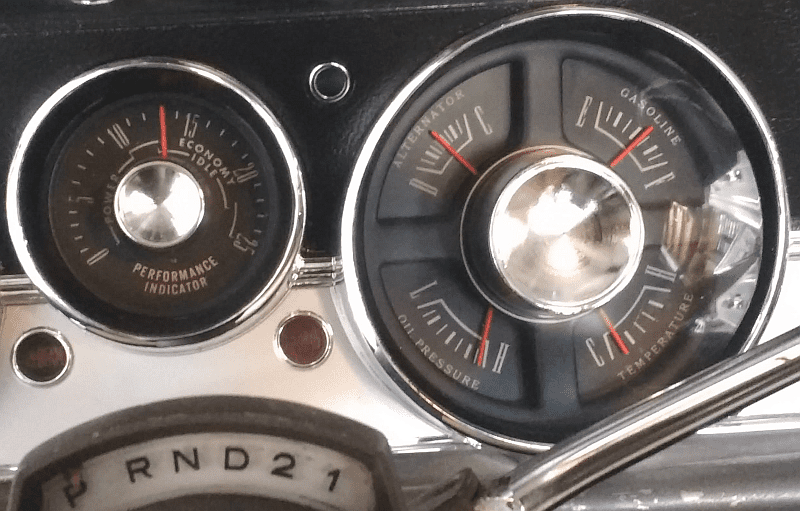

Got around to investigating the high oil pressure readings on the factory gage of my '67 Barracuda.

Starting a new thread instead of sidetracking the original thread further...

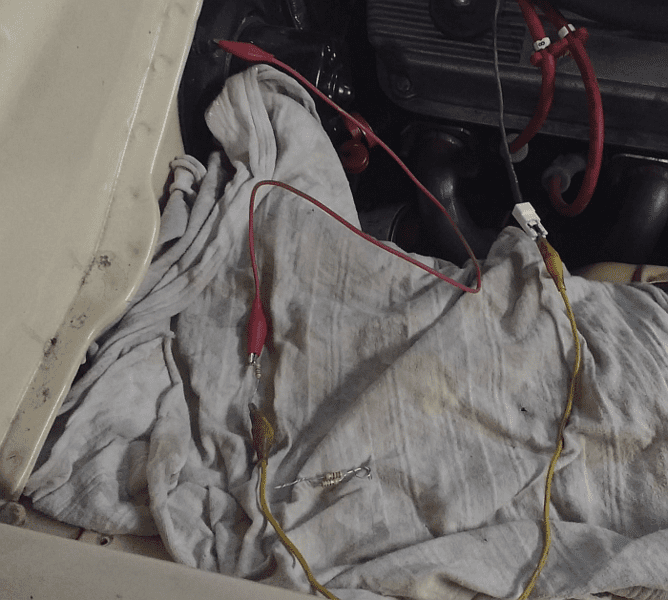

I tested the gage operation using resistors and compared with the information from @RedFish and others. Summary: Using resistors clipped to the sending unit wire and body ground, the gage indicates properly.

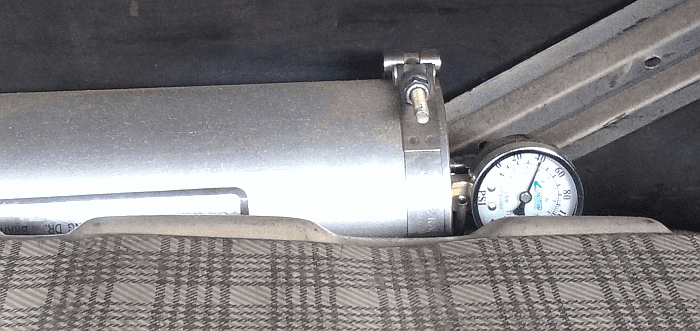

Tested the sending unit by measuring the resistance with a digital multimeter with the engine running and comparing with the mechanical gage on the accsump. Summary. Sending unit resistance is very jumpy although it seems to average approximately correct.

Here's a video clip of it idling after warming up. Gage on accusump shows 40 psi.

My best guess is the sending unit should not be jumping around, and due to the difference in operation between the dash gage and an ohmeter, too much current is flowing through gage.

Does that make sense? Anyone have another possibility?

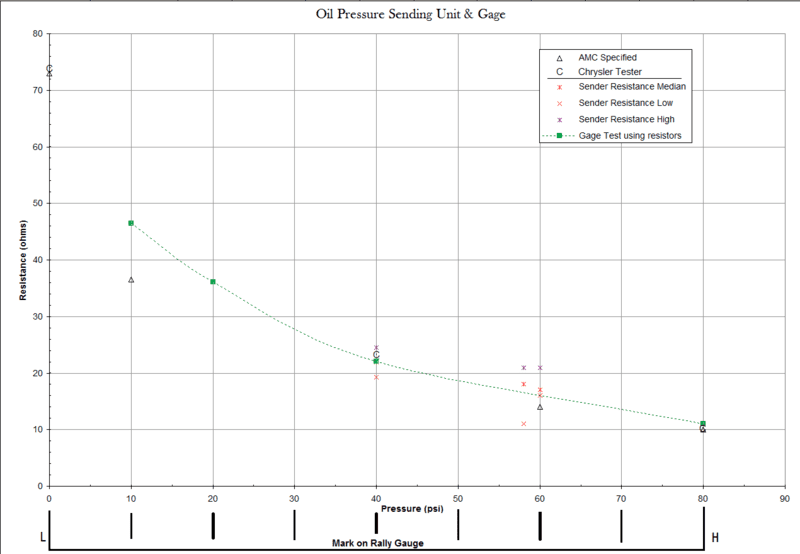

Here's a graph of the gage test with resistors (green squares)

The range of readings from the sender at 40 psi and around 60 psi are red and purple x.

Single 22 ohm resistor connected to sending wire.

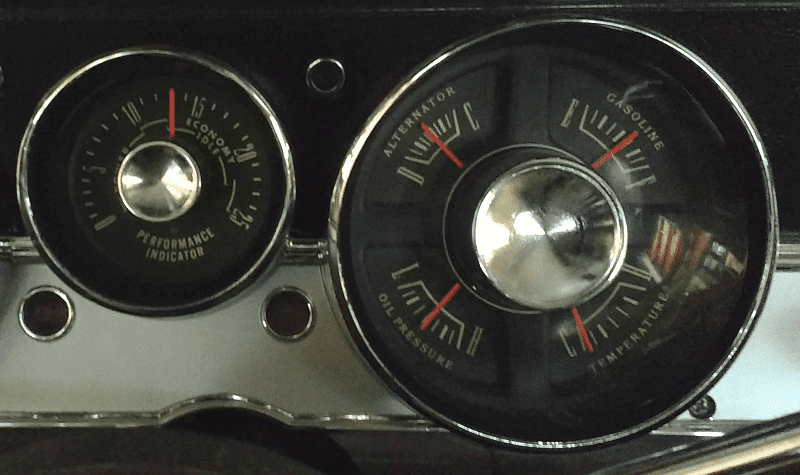

Gage indicates center approximately 40 psi.

In contrast when the mechanical gage on the accusmp shows 40 psi

And the sender wire is connected, the dash gage shows around 70 - 75 psi.

Refer to the video above for the sender resistance at 40 psi.

Backstory here Rally dash redo

Starting a new thread instead of sidetracking the original thread further...

I tested the gage operation using resistors and compared with the information from @RedFish and others. Summary: Using resistors clipped to the sending unit wire and body ground, the gage indicates properly.

Tested the sending unit by measuring the resistance with a digital multimeter with the engine running and comparing with the mechanical gage on the accsump. Summary. Sending unit resistance is very jumpy although it seems to average approximately correct.

Here's a video clip of it idling after warming up. Gage on accusump shows 40 psi.

My best guess is the sending unit should not be jumping around, and due to the difference in operation between the dash gage and an ohmeter, too much current is flowing through gage.

Does that make sense? Anyone have another possibility?

Here's a graph of the gage test with resistors (green squares)

The range of readings from the sender at 40 psi and around 60 psi are red and purple x.

Single 22 ohm resistor connected to sending wire.

Gage indicates center approximately 40 psi.

In contrast when the mechanical gage on the accusmp shows 40 psi

And the sender wire is connected, the dash gage shows around 70 - 75 psi.

Refer to the video above for the sender resistance at 40 psi.

Backstory here Rally dash redo

Oil pressure gauge looks reading too high. They are just basic range indicators but... in calibrating approx' 60 psi should be at the 'U' in PRESSURE. Not sure why I can remember that when I can't remember what the center test point of 23 ohms was equal to in PSI. I'll go to the book later today.

I would get the gray wire off that sender now. Could be overheating that gauge.

edit; Curiosity got me so went to look... 23 ohms on this gauge is 40 psi +/- 5. and you gauge is now showing well over 80 psi which is as far as the scale/chart goes.

Last edited: