Hi guys,

First post here but I have been reading these forums for quite a while - Lots of good info on this site.

Anyway I am looking for second opinions on a cam that was recommended for my 318 by a local grinder.

I was originally looking at a howards 711651-10 for this engine (265/273adv, 218/[email protected]", .502/525 lift) but they reckon 3-4 months wait time on the cam, then another 3-4 weeks for international shipping.

Car is a 1969 valiant VF coupe (Australian dodge dart), 3100lbs, 3.23 gears, 245/60R15 tires, power brakes, 904 torqueflight with shift kit, have a std convertor at the moment but will probably swap this to a higher stall unit to match the cam.

Engine is a 1973 casting 318 +0.060 bore (327CI).

KB 167 pistons (0.013" above deck) 9.8:1 CR with 0.051" head gasket, resized std rods with arp bolts, floating pistons, crank reground and rotating assembly balanced.

Have a edelbrock 650CFM AVS2 carb and mildly ported Weiand action plus dual plane manifold, 1 5/8" tri-y headers twin 2.5" exhaust.

Aeroflow alloy heads - 2.02" inlet & 1.6" exhaust valves with casting flash in the ports cleaned up, some bowl blending and a decent valve job. These flow similar to edelbrock & speedmaster heads OOTB but they haven't been flowed after the cleanup on them. 1.6 ratio rockers.

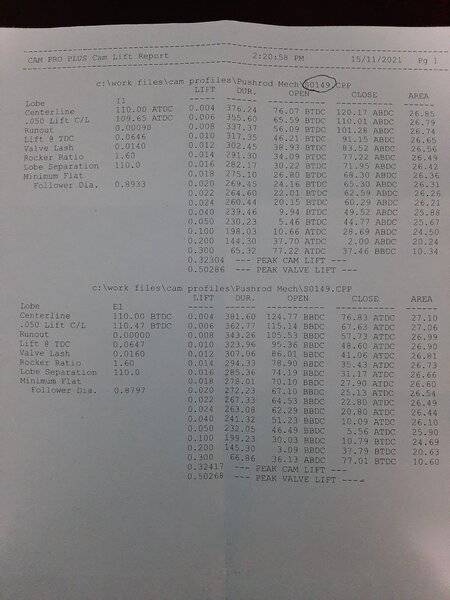

The cam recommended from my local grinder is a solid flat tappet but to me seems a little bit big for my intended use (street car/cruiser with a bit of punch) what do you guys think?

Hopefully cam specs are attached, will be installed on 106° intake centreline.

Is it safe to compare a solid cam duration advertised at 0.020" with a hydraulic advertised at 0.006"? Or is there more to it when comparing solid to hydraulic profiles?

Cheers,

Ted

First post here but I have been reading these forums for quite a while - Lots of good info on this site.

Anyway I am looking for second opinions on a cam that was recommended for my 318 by a local grinder.

I was originally looking at a howards 711651-10 for this engine (265/273adv, 218/[email protected]", .502/525 lift) but they reckon 3-4 months wait time on the cam, then another 3-4 weeks for international shipping.

Car is a 1969 valiant VF coupe (Australian dodge dart), 3100lbs, 3.23 gears, 245/60R15 tires, power brakes, 904 torqueflight with shift kit, have a std convertor at the moment but will probably swap this to a higher stall unit to match the cam.

Engine is a 1973 casting 318 +0.060 bore (327CI).

KB 167 pistons (0.013" above deck) 9.8:1 CR with 0.051" head gasket, resized std rods with arp bolts, floating pistons, crank reground and rotating assembly balanced.

Have a edelbrock 650CFM AVS2 carb and mildly ported Weiand action plus dual plane manifold, 1 5/8" tri-y headers twin 2.5" exhaust.

Aeroflow alloy heads - 2.02" inlet & 1.6" exhaust valves with casting flash in the ports cleaned up, some bowl blending and a decent valve job. These flow similar to edelbrock & speedmaster heads OOTB but they haven't been flowed after the cleanup on them. 1.6 ratio rockers.

The cam recommended from my local grinder is a solid flat tappet but to me seems a little bit big for my intended use (street car/cruiser with a bit of punch) what do you guys think?

Hopefully cam specs are attached, will be installed on 106° intake centreline.

Is it safe to compare a solid cam duration advertised at 0.020" with a hydraulic advertised at 0.006"? Or is there more to it when comparing solid to hydraulic profiles?

Cheers,

Ted