1969VADart

Well-Known Member

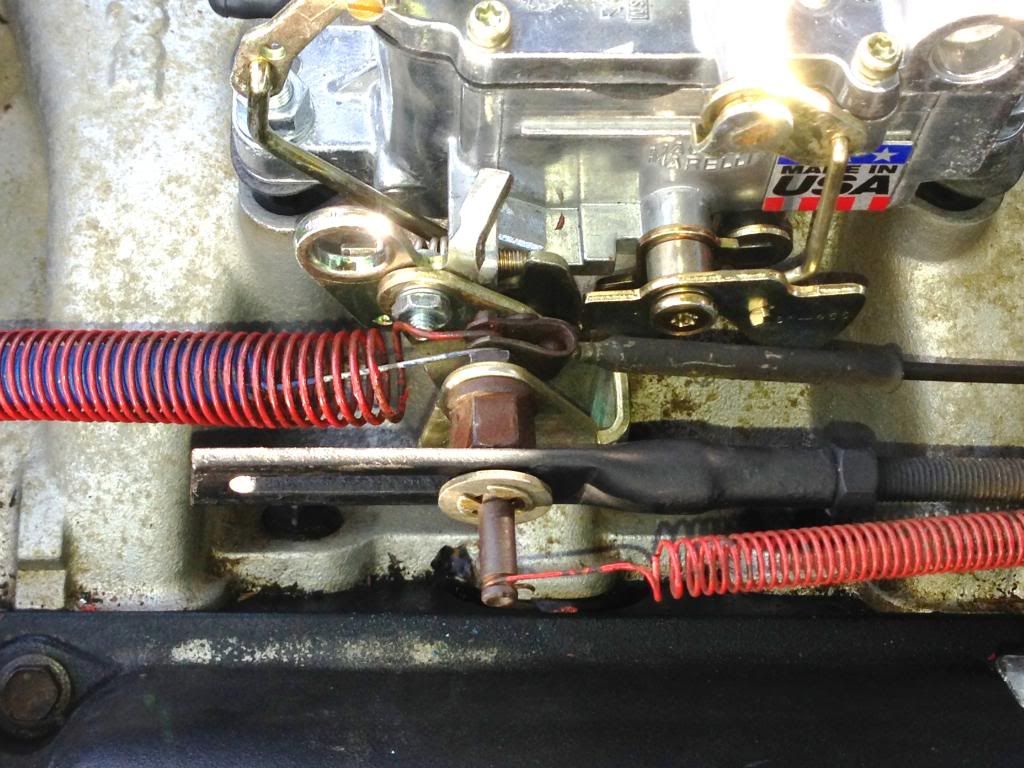

When I installed the Edelbrock carburetor on my 69 Dart I went ahead and decided to install a phenolic spacer after I experienced some of the common heat soak issues and fuel boiling in the carb. I originally installed a 1" spacer, but when I connected the throttle return spring and throttle cable it pulled the carb linkage partially open. I decided to switch to a 1/2" phenolic spacer, but while cruising around town, I still developed some mild fuel boiling problems. I would like to switch back to the 1" spacer to hopefully alleviate the fuel boiling problems completely. I really only need about 1/2-3/4" in extra length for the throttle cable. Is there a way to lengthen the cable (or give me some extra length), or am I likely stuck having to buy a new throttle cable. I realized when I first pulled the throttle cable out of its mounting bracket, it just pulled the accelerator pedal down towards the floor (probably an obvious fact to the more automotively inclined). The carb came with a throttle linkage adapter, but I could not see how it would attach to the old style cable end (the the u-shaped connector with the cable ball inside that attaches to the rod on the carb linkage). Any thoughts or pictures of how you guys made the 1" spacer work would be appreciated.