dibbons

Well-Known Member

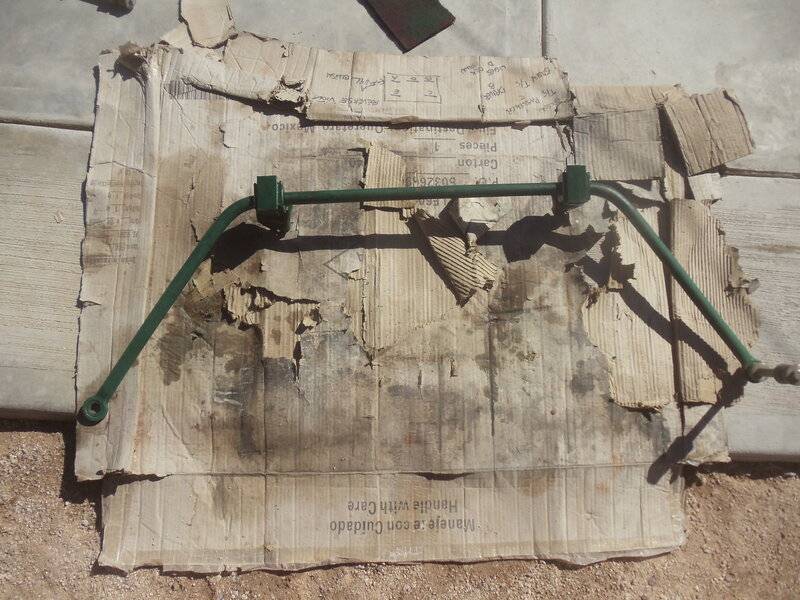

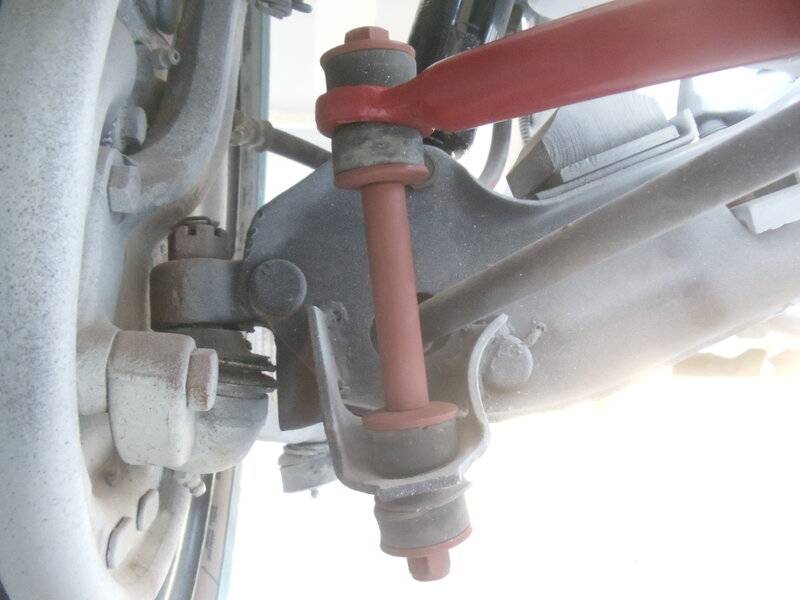

Update: No more John Deere green. Painted the sway bar RustOleum "colonial red" (same as fuel tank) and installed. Still need to tighten down the end links some more. Had to pry down on the end links with a long wood stick used as a fulcrum lever to get enough threads to start the nut.

Last edited: