It operates at 15, blow off valve is 30. But to your point...its holding 30, so I'm probably good. Thanks!!around 8 or 9 psi seems to be the sweet spot . The blow off valve is most likely 15 psi .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

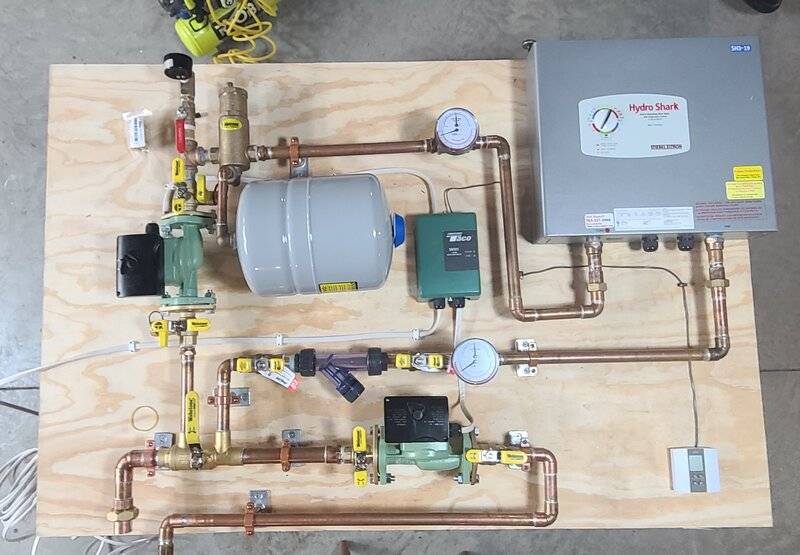

Psi rating for radient floor heat panel test???

- Thread starter Johnny Mac

- Start date

-

I at least have the soapy bubble leaks fixed.I know this may sound like a stupid question but did you solder any pipe to sweat adapters while they were made up?

If so thats your problem.

Hercules makes some good pipe sealants, you should check that out

Any threaded fitting that you see leaking bubbles when you apply soapy water or leak detector at 30 psi is a "leak" No way should you see anything leaking (bubbles) at those joints.

What do you mean solder while the adapters were made up? Like if I had a doped up npt connection together, then got it hot by soldering next to it? No, all soldering was done before any NPT.

Steve welder

Well-Known Member

Yes, I meant soldering a copper fitting after it was made up to a threaded fitting. I figured you didn't do that but I had to ask. My apologiesI at least have the soapy bubble leaks fixed.

What do you mean solder while the adapters were made up? Like if I had a doped up npt connection together, then got it hot by soldering next to it? No, all soldering was done before any NPT.

If I had to guess id also say the seals at the circulator could be were some slight amount of air is leaking

I have radiant heat in my kitchen, a small section were the sink and cabinets of my kitchen is over a crawl space and it was always cold there, we ran some of the tubing actually under the floor there now its warm and comfortable on even the coldest days

It's a valid question. On that 2 way splitter valve, I had no choice but to sweat it. I was nervous about melting that seal, but was careful with heat, and used water to keep that part cool/isolated.Yes, I meant soldering a copper fitting after it was made up to a threaded fitting. I figured you didn't do that but I had to ask. My apologies

If I had to guess id also say the seals at the circulator could be were some slight amount of air is leaking

I have radiant heat in my kitchen, a small section were the sink and cabinets of my kitchen is over a crawl space and it was always cold there, we ran some of the tubing actually under the floor there now its warm and comfortable on even the coldest days

One thing i know for sure is the thicker your floor is the more efficient the heating is . i have one building with a 4'' floor and one with an 8'' -9'' floor ,the thicker floor heats better and cost less to heat over the winter . the extra cement will soon pay for itself .

6PakBee

Well-Known Member

When I put my floor heat in I used the Loctite sealant on the threaded fittings. Three years later and zero leaks.Loctite brand ptfe thread lubricant/sealant paste. It’s the only one I’ll use and I have excellent results with it.

LOCTITE 5113

For anyone mildly interested in my immense failure of the complexity that is the npt joint... lol

For whatever reason, regular old Teflon tape, and my trusty white ptfe permatex paste, had about a 60% failure rate. (Didn't mix them, just switched back and forth pending the joint location and complexity) Like I said, I had these joints tight to the point I was anticipating cracking brass (or plastic). Leak testing kept revealing soapy bubbles on one, fix it, then another, then fix that, then another, on and on.

I ran to home depot and grabbed a roll of $5 blue monster Teflon tape (wanted to get this wrapped up instead of waiting on something I had to ship)

And be it correct or not, I re wrapped the joints with the blue tape, AND put a dab of paste on the bottom. FINALLY have it holding air over night, and all wired up!

For whatever reason, regular old Teflon tape, and my trusty white ptfe permatex paste, had about a 60% failure rate. (Didn't mix them, just switched back and forth pending the joint location and complexity) Like I said, I had these joints tight to the point I was anticipating cracking brass (or plastic). Leak testing kept revealing soapy bubbles on one, fix it, then another, then fix that, then another, on and on.

I ran to home depot and grabbed a roll of $5 blue monster Teflon tape (wanted to get this wrapped up instead of waiting on something I had to ship)

And be it correct or not, I re wrapped the joints with the blue tape, AND put a dab of paste on the bottom. FINALLY have it holding air over night, and all wired up!

Demonic

Well-Known Member

Really, good pipe threads are usually foolproof. I'm still suspecting something amiss, like a bad flank, or root, maybe pitch. Glad you got it sealed up. Biggest thing is to keep the dope or tape 3/4 to 1 thread back from the end. No junk inside the valves or other devices. I hate teflon tape - the second time you assemble it. The bits get inside the system.

en.wikipedia.org

en.wikipedia.org

National pipe thread - Wikipedia

Thanks for that optimistic point of view!!! I was glad to get it under wraps.Sounds like you have it under control. That means it’s not a failure in my opinion.

-