Obviously velocity is important but I'm at the belief that the average person doesn't have to much say about it, especially in the Mopar world, we have relatively few choices of off the shelf parts to work with.

Most the calculations below are based on cid and rpm, when building an engine obviously cid will be fixed once built, now rpm even if the parts are well chosen to make power at X rpm, doesn't mean the build will cooperate.

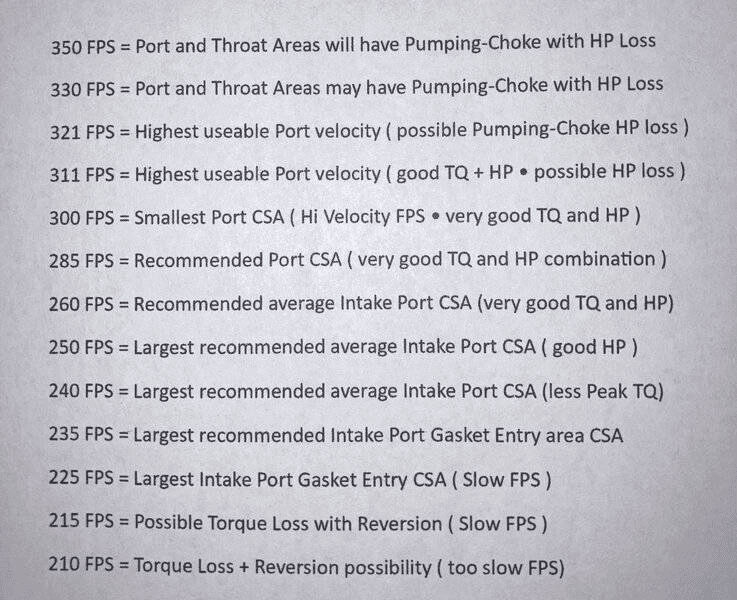

So Pic below gives varied results for different FPS, this based on slight mismatch of velocity (cfm and or port cc) for a given cid and rpm.

My question is

Eg.. you are building a 6500 rpm 360 and says you need X cfm and Y port cc to hit 285 FPS, but say head choice has the right cfm but the port is too big it's gonna be more in the 210 FPS which seems unacceptable or near it.

So my question is on paper this is less than ideal but wouldn't the engine be able to possibly self correct a little ?

Maybe with the bigger port the engine makes power at like 6700-7000 rpm instead of 6500 rpm and bring up the FPS with it, rpm is gonna be flexible.

There's a Richard Holdener video where he does a bunch of LS heads in a similar ballpark but varied enough in port size and cfm, and all basically make the same average hp and tq but peak power varies a little, doesn't show the velocities for the heads possibly they could be very similar why the results.

But generally were not up against an rpm wall, generally people want X hp out of Y cid leaving at what rpm a little vague leaving it hard to design for a certain velocity.

To restate my basic question isn't the engine probably gonna somewhat try to make power at a somewhat decent velocity self rectify a little by rpm ?

Pic I borrowed from Earlie A

Most the calculations below are based on cid and rpm, when building an engine obviously cid will be fixed once built, now rpm even if the parts are well chosen to make power at X rpm, doesn't mean the build will cooperate.

So Pic below gives varied results for different FPS, this based on slight mismatch of velocity (cfm and or port cc) for a given cid and rpm.

My question is

Eg.. you are building a 6500 rpm 360 and says you need X cfm and Y port cc to hit 285 FPS, but say head choice has the right cfm but the port is too big it's gonna be more in the 210 FPS which seems unacceptable or near it.

So my question is on paper this is less than ideal but wouldn't the engine be able to possibly self correct a little ?

Maybe with the bigger port the engine makes power at like 6700-7000 rpm instead of 6500 rpm and bring up the FPS with it, rpm is gonna be flexible.

There's a Richard Holdener video where he does a bunch of LS heads in a similar ballpark but varied enough in port size and cfm, and all basically make the same average hp and tq but peak power varies a little, doesn't show the velocities for the heads possibly they could be very similar why the results.

But generally were not up against an rpm wall, generally people want X hp out of Y cid leaving at what rpm a little vague leaving it hard to design for a certain velocity.

To restate my basic question isn't the engine probably gonna somewhat try to make power at a somewhat decent velocity self rectify a little by rpm ?

Pic I borrowed from Earlie A

- Average_CSA = Port_Volume_CC / (Port_CenterLine_Length * 16.387)

- MIN CSA = (Bore x Bore x Stroke x RPM x .00353) / 613.8 (.55 MACH)

- Port_Volume_CC = Average_CSA * Port_CenterLine_Length * 16.387

- Port_CenterLine_Length = Port_Volume_CC / ( Average_CSA *16.387 )

- FPS = ( Flow_CFM * 2.4 ) / Average_CSA

- Flow_CFM = Average_CSA * FPS * .4166667

- Average_CSA = ( Flow_CFM * 2.4) / FPS

- cfm demand = cid x rpm x .0009785 / # of cylinders

Last edited: