paul smart

Well-Known Member

hey fellas just wondering whos running a main stud girdle on their big block and curious if tour running a windage tray.just doing the math if running both you would have to run 3 oil pan gaskets

if i tack welded the windage tray to the girdle you migh not be able to acces the bolts correct?

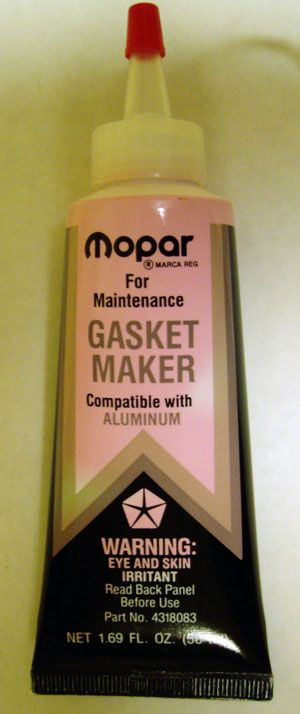

Use a stock stroke windage tray. Silicone the girdle to the block, then silicone windage tray to the girdle, use one gasket between pan and windage tray. That's the way I do them.

These are nice. We have been using them with no leaks yet.

http://www.summitracing.com/parts/sum-g2340

no problem using the right stuff no leaks mike