I would like to replace the intake valve seat inserts in a small block Speedmaster head. Current valve size is 2.02. Anyone have any part number or supplier references? Existing seat outside diameter appears to be about 2.185" and thickness around 0.350.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacement Valve Seats

- Thread starter Earlie A

- Start date

-

Newbomb Turk

Well-Known Member

2.185 sounds like an oddball size but why change them? You can run a 2.150 valve on that seat all day long.

If you are sure on the size leave it alone.

If you are sure on the size leave it alone.

Professor Fate

Push the button, Max...

Call Speedmaster. They list valve seats on their website, ask them which ones are used in their heads and have them send you some.

But I agree with N.T.- I wouldn't mess with them unless there's something wrong with them.

But I agree with N.T.- I wouldn't mess with them unless there's something wrong with them.

@pittsburghracer can probably tell you.

Thanks guys. These are flow testing heads. Trying to find the best performance out of a 2.02 valve. Factory throat on one head is 90.5%. Factory throat on a factory CNC head is 93%. I want to try a smaller throat before I try a larger valve.

@pittsburghracer can probably tell you.

I’ll try to see if I have the part number in my shop if I hopefully remember tomorrow. I think before I would change a seat for this experiment I would use splash zone epoxy to make my throat a little bigger. It’s very easy to work with and if you wanted to play with 88-89-90-91% throat it would be very easygoing.

Just asking a simple question here but how much "extra" flow are you looking for? Enough for all the work?

Just asking a simple question here but how much "extra" flow are you looking for? Enough for all the work?

He’s learning and that’s priceless.

How does the Splash Zone cut on a seat and guide machine?

I think if you took it slow and easy you could do it.

I certainly cannot disagree with that.He’s learning and that’s priceless.

Newbomb Turk

Well-Known Member

Thanks guys. These are flow testing heads. Trying to find the best performance out of a 2.02 valve. Factory throat on one head is 90.5%. Factory throat on a factory CNC head is 93%. I want to try a smaller throat before I try a larger valve.

Unless you close up the bowls, use a larger valve or a steeper seat you‘ll be in trouble. Those bowls are too big for that valve. I’m not sure why they do it, but they do.

To which of the two heads are you referring? If you are talking about the Speedmaster factory CNC ported head, I will agree with you that they are unimpressive. 200cc port, 93% throat and 266 cfm peak on my bench. They are almost forcing you to install a larger valve. If you are referring to the non ported Speedmaster head, I'd love to hear more. By the way, the port I am currently working with (on the non CNC head) has the valves sunk 0.090" and 50 degree seats.Unless you close up the bowls, use a larger valve or a steeper seat you‘ll be in trouble. Those bowls are too big for that valve. I’m not sure why they do it, but they do.

How do you replace an existing valve seat with one the same size? Seems to me I would have to go oversized with the new seat. Never going to get the bore in exactly the same location twice. But this is just me thinking - I've never done one.Call Speedmaster. They list valve seats on their website, ask them which ones are used in their heads and have them send you some.

But I agree with N.T.- I wouldn't mess with them unless there's something wrong with them.

To which of the two heads are you referring? If you are talking about the Speedmaster factory CNC ported head, I will agree with you that they are unimpressive. 200cc port, 93% throat and 266 cfm peak on my bench. They are almost forcing you to install a larger valve. If you are referring to the non ported Speedmaster head, I'd love to hear more. By the way, the port I am currently working with (on the non CNC head) has the valves sunk 0.090" and 50 degree seats.

I’ve never bought the cnc heads nor never will but the stock head can be hand ported to flow 290cfm with their 2.02 valves.

RAMM

Well-Known Member

You run a TIG torch around the ID and it will shrink the seat and pretty much fall out. J.RobHow do you replace an existing valve seat with one the same size? Seems to me I would have to go oversized with the new seat. Never going to get the bore in exactly the same location twice. But this is just me thinking - I've never done one.

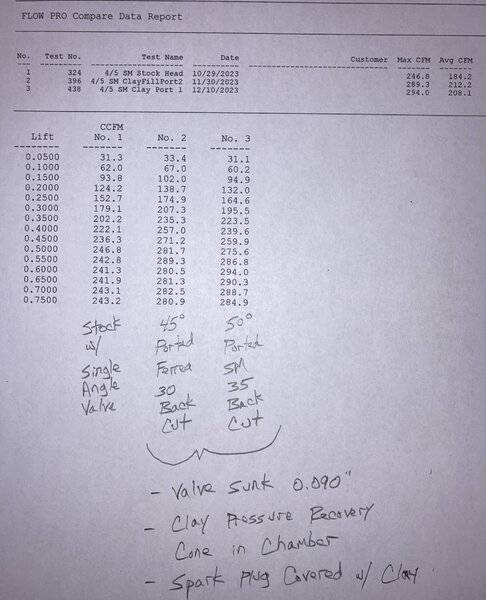

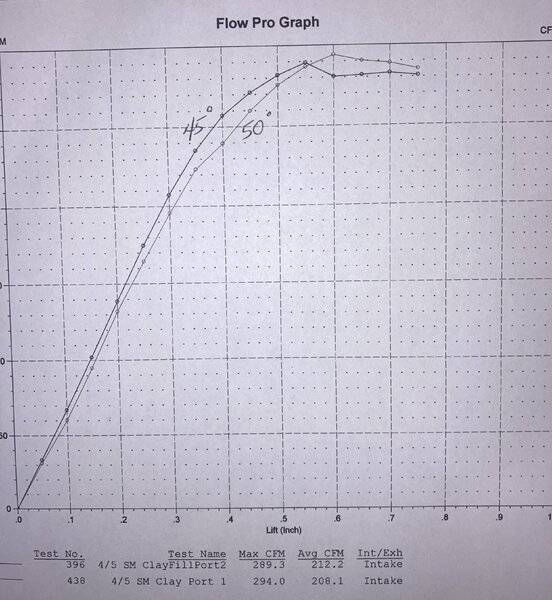

That's about what I have found. I've hit 290 with 45 degree seats and 294 with 50 degree seats, but that's with clay in the chamber, so I guess it's cheating. My ports are also not that stable beyond 500 lift, so I have work to do.I’ve never bought the cnc heads nor never will but the stock head can be hand ported to flow 290cfm with their 2.02 valves.

That's about what I have found. I've hit 290 with 45 degree seats and 294 with 50 degree seats, but that's with clay in the chamber, so I guess it's cheating. My ports are also not that stable beyond 500 lift, so I have work to do.

It’s a lot of work to take 20-25cc out of these heads but I’m not paying anyone to cnc it for me. I’m stubborn that way

You run a TIG torch around the ID and it will shrink the seat and pretty much fall out. J.Rob

That’s crazy how that works. During my Millwright years we heated things to make them expand. And dry ice and alcohol (old days) or liquid nitrogen to shrink things.

That's about what I have found. I've hit 290 with 45 degree seats and 294 with 50 degree seats, but that's with clay in the chamber, so I guess it's cheating. My ports are also not that stable beyond 500 lift, so I have work to do.

Here’s my old flowsheet from my last set. Sorry for the scribble

Looking at your numbers I can hear how quiet and stable your port is. Mine is all over the place starting with a few minor noises at 300, then quiet again, then unstable from 500 and beyond. The clay in the chamber really helps pick up the mid lift flow, but obviously it's just experimental. Thanks for posting. That really gives me a benchmark.

Looking at your numbers I can hear how quiet and stable your port is. Mine is all over the place starting with a few minor noises at 300, then quiet again, then unstable from 500 and beyond. The clay in the chamber really helps pick up the mid lift flow, but obviously it's just experimental. Thanks for posting. That really gives me a benchmark.

View attachment 1716187201

When I see a big jump like that at .500 I know I have work to do yet, usually at the short turn. Can you check airspeed??? I’m betting you are over 400fps or close. You are so close to being golden. Are you building up the floor to get there?

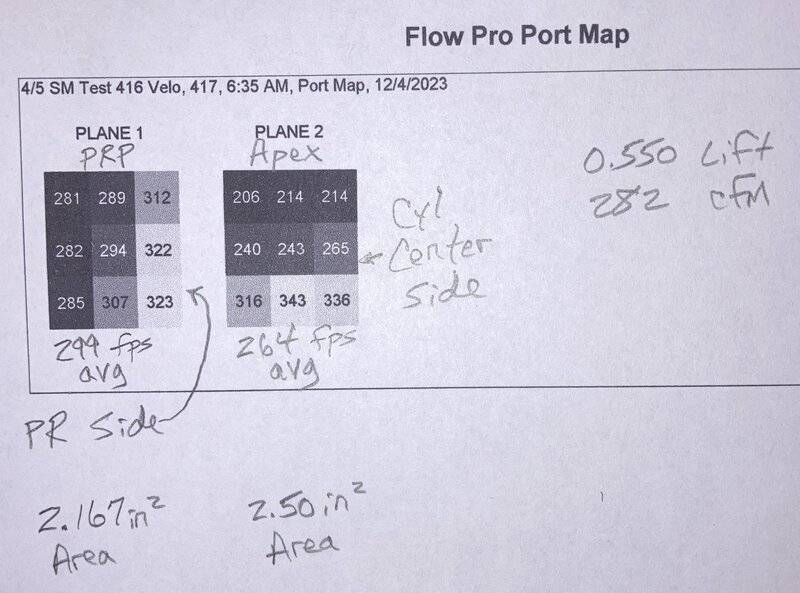

Here's a recent port map with the 45 degree seats, 550 lift, 282 cfm. For a variety of reasons, I'm starting to suspect my pitot tube reads low. Just got a new one from Bruce at PTS yesterday. Hope to try it tonight.

However, the 264 fps average (from the pitot) at the SSR, and the calculated average of 270 fps based on 2.5 square in area at the SSR and 282 cfm are not that far off.

Floor is not raised, but I have tried that with clay. Didn't help. If anything, the floor is effectively lower because the valves have been sunk 0.090".

However, the 264 fps average (from the pitot) at the SSR, and the calculated average of 270 fps based on 2.5 square in area at the SSR and 282 cfm are not that far off.

Floor is not raised, but I have tried that with clay. Didn't help. If anything, the floor is effectively lower because the valves have been sunk 0.090".

I can see something is not right more by looking at this graph than looking at the raw data. The 45 degree seat curve has a great shape until 550 lift, then the stall takes over. It can be heard earlier than 550. I know this is a common phenomenon in low port heads, but I want to understand it and fix it to the extent possible. Here are the things I've tried:

PRP - Now at 2.167 sq in and about 300 fps avg velocity. I think it is large enough.

Chamber stall - Erland Cox on Speedtalk has some good threads about flow separation starting in the chamber and working backwards up the port. I've made a lot of clay cones in the chamber and even flowed the port without a valve but with a 2" long 7 degree diverging cone built on to the port exit. No amount of chamber mods made any significant change to the flow above 600 lift.

Port CSA prior to the apex - I have increase width, but also some height prior to the apex to reduce velocity at the SSR. Now at or above 2.5 square in. Erland Cox also has some good posts about air speeding up over the short turn instead of slowing down. He makes some compelling points.

Guide boss - Fairly significant streamlining, but may still need work. There is turbulence beside the guide on the cyl center side at 280 cfm.

I have tried not to touch the throat, but with a 90.5% throat from the factory, my valve jobs have increased it to 91%+. Hence my desire to try a smaller throat. This is also part of Erland's arguments for converging over the short turn instead of diverging into a larger bowl.

I have worked some on the SSR, more on the edges than in the middle. I understand this is where the magic happens. It's also the most difficult to learn. So I've saved it for last.

PRP - Now at 2.167 sq in and about 300 fps avg velocity. I think it is large enough.

Chamber stall - Erland Cox on Speedtalk has some good threads about flow separation starting in the chamber and working backwards up the port. I've made a lot of clay cones in the chamber and even flowed the port without a valve but with a 2" long 7 degree diverging cone built on to the port exit. No amount of chamber mods made any significant change to the flow above 600 lift.

Port CSA prior to the apex - I have increase width, but also some height prior to the apex to reduce velocity at the SSR. Now at or above 2.5 square in. Erland Cox also has some good posts about air speeding up over the short turn instead of slowing down. He makes some compelling points.

Guide boss - Fairly significant streamlining, but may still need work. There is turbulence beside the guide on the cyl center side at 280 cfm.

I have tried not to touch the throat, but with a 90.5% throat from the factory, my valve jobs have increased it to 91%+. Hence my desire to try a smaller throat. This is also part of Erland's arguments for converging over the short turn instead of diverging into a larger bowl.

I have worked some on the SSR, more on the edges than in the middle. I understand this is where the magic happens. It's also the most difficult to learn. So I've saved it for last.

-