Swapping a 318 to 340 that was a 4 speed. The 340 bushing/pilot came out ez enough. The 318 auto was being stubborn and decided to leave in for various reasons.

I had converted a manual to auto 45 years ago and do not recall dealing with the bushing in crank to accommodate the converter. Of course being more ignorant then ( maybe ), I probably bolted up and ran it.

After a frustrating amount of time looking for info and the actual part, I'd like to understand how the bushing relates to the assembly.

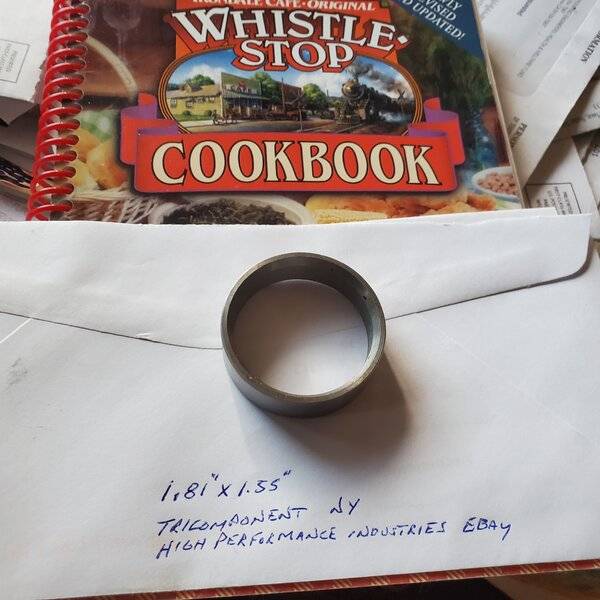

The only source found for a 1.81x1.55 inch bushing is in the picture. It took about a week to get and was the last piece of the puzzle needed for the swap. Engine biscuits needed were also a pain with Classic Industries being the savior.

I had converted a manual to auto 45 years ago and do not recall dealing with the bushing in crank to accommodate the converter. Of course being more ignorant then ( maybe ), I probably bolted up and ran it.

After a frustrating amount of time looking for info and the actual part, I'd like to understand how the bushing relates to the assembly.

The only source found for a 1.81x1.55 inch bushing is in the picture. It took about a week to get and was the last piece of the puzzle needed for the swap. Engine biscuits needed were also a pain with Classic Industries being the savior.