You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rotor thickness minimum 4-piston KH?

- Thread starter ppsi

- Start date

-

Should be in the FSM

Agreed however I don't have a FSM for this car yet.Should be in the FSM

MY mopar has them on line in a pinch.

http://www.mymopar.com/index.php?pid=109

http://www.mymopar.com/index.php?pid=109

pishta

I know I'm right....

.810? 69 KH doesnt show minimum but Bendix was max .860, replace at .810.

<<<correction>> min thickness on new rotor is .790.---.810 is new.

<<<correction>> min thickness on new rotor is .790.---.810 is new.

Last edited:

FSM says to not turn them mostly cause in 1968 the factory had little confidence in the lathes then in use to maintain run-out and thickness. Today they are taking them down to .750

FSM says to not turn them mostly cause in 1968 the factory had little confidence in the lathes then in use to maintain run-out and thickness. Today they are taking them down to .750

Today they are taking them down to .750

Not true.

Where did you come up with that figure anyway????

.790 is the minimum.

Always has been, always will be.

That will be one paper thin rotor, at that specification.

Don't go posting inaccurate information.

Whose "They" are taking them down to .750 anyway????

Last edited:

67Dart273

Well-Known Member

There are a couple of dangers in the rather heavy, "twin wall" old school rotors. One is that you get the web that connects the rotor proper to the hub too thin. You can actually check this by drilling a couple of say, 1/8" "check" holes in the web.

One other danger is that you get the rotor thin enough that the caliper pistons will lose their seal and dump brake fluid.

"In my early days" there was a private, 3rd party "ski bus" to Schweitzer mountain. This was a wide body van in the mid 70's with front disc, 1 ton. Someone brought them into the store and I refused them. The mech. gave me trouble so I actually took him back and DRILLED a check hole in the web. These rotors were WAY beyond use.

Months later someone brought that rotor back---in two pieces. They accused us of the trouble, and I recognized one of them from the 1/8 hole. Told them if they were going to sue, they better come up with an invoice.

One other time, someone brought in a pair of Chev pass car rotors, they were more than .130 below the "toss" figure. This was BEFORE I would have turned them, and was measuring "the high spots" with a common caliper. So the "low spots" were way worse!! I refused them, the mech ran them up to the N end to 'that other store' and those dummies turned them no problem. Then I "was the ***" according to him

One other danger is that you get the rotor thin enough that the caliper pistons will lose their seal and dump brake fluid.

"In my early days" there was a private, 3rd party "ski bus" to Schweitzer mountain. This was a wide body van in the mid 70's with front disc, 1 ton. Someone brought them into the store and I refused them. The mech. gave me trouble so I actually took him back and DRILLED a check hole in the web. These rotors were WAY beyond use.

Months later someone brought that rotor back---in two pieces. They accused us of the trouble, and I recognized one of them from the 1/8 hole. Told them if they were going to sue, they better come up with an invoice.

One other time, someone brought in a pair of Chev pass car rotors, they were more than .130 below the "toss" figure. This was BEFORE I would have turned them, and was measuring "the high spots" with a common caliper. So the "low spots" were way worse!! I refused them, the mech ran them up to the N end to 'that other store' and those dummies turned them no problem. Then I "was the ***" according to him

FYIAnyone know the minimum thickness? These are for a 68 dart gt.

Thanks

Could have found out by looking on the back side of the rotor, with the minimum specs stamped into it.

I believe the larger question is: are you making one face thinner that the opposite side. If you were taking it down to .750", by removing the stock form one of the two sides, you could create a bad condition.

I know we're all smarter than that, but it needs to be said

I know we're all smarter than that, but it needs to be said

Yup. I checked the back and it looks like. 790 is the number.

I've read about these twin wall rotors but I don't think I'm going to change them unless the guy turning them says they will be too thin.

I'll have to reread the thin web/1/8"

Thanks. They don't list a FSM for a 1968 dart. I'll look for a reprint.

Thanks

I've read about these twin wall rotors but I don't think I'm going to change them unless the guy turning them says they will be too thin.

I'll have to reread the thin web/1/8"

MY mopar has them on line in a pinch.

MyMopar - Mopar Forums & Information - Service Manuals

Thanks. They don't list a FSM for a 1968 dart. I'll look for a reprint.

Thanks

67Dart273

Well-Known Member

I believe the larger question is: are you making one face thinner that the opposite side. If you were taking it down to .750", by removing the stock form one of the two sides, you could create a bad condition.

I know we're all smarter than that, but it needs to be said

I have NEVER found a rotor on which this was an issue. As long as the caliper "float" device has room you are OK, including pistons

I was in the automotive repair industry for over 35 years and we serviced thousands of brake systems since the seventies. What should be done and what people sometimes get away with are different discussions. Both rotors should be the same thickness to have equal heat expansion. Doesn't matter what caliper system you have. Just like both front drums should be the same specs. Braking is all about converting motion into heat. Rotors are inexpensive and very important safety items. Like having a bald tire on one side and a new tire on the other. When you make a hard stop, traction will not be equal. Be sure to flush all the brake fluid from the system at least every brake service with new un-opened containers of brake fluid. Drum and rotor specs are always cast into them. Back in the sixties some drums were manufactured thicker and could be machined up to .090 under size. This was also normally cast into the drum. 2 most important safety items on any vehicle are the brakes and tires. Everything else is less important.

Last edited:

Read it in Mopar action about 25 years ago. Never turned one myself so ya, I should keep my mouth shut.Today they are taking them down to .750

Not true.

Where did you come up with that figure anyway????

.790 is the minimum.

Always has been, always will be.

That will be one paper thin rotor, at that specification.

Don't go posting inaccurate information.

Whose "They" are taking them down to .750 anyway????

I bought a pair of new crossdrilled slotted rotors for $83 last year, so it really isn't worth risking your ride on worn-out rotors.

Download the Plymouth version. It has almost all the same info as the Dodge version.Yup. I checked the back and it looks like. 790 is the number.

I've read about these twin wall rotors but I don't think I'm going to change them unless the guy turning them says they will be too thin.

I'll have to reread the thin web/1/8"

Thanks. They don't list a FSM for a 1968 dart. I'll look for a reprint.

Thanks

If you buy a reprint, don't buy from Faxon. They have the lowest quality.

Try Bishko or just about anyone else for that matter.

If you have to buy new rotors, get ones where the 'hat' that goes over the hub has been machined. Every time I've checked the castings all seem to be the same - which means the as-cast hat will kiss the pistons boots every rotation.

if you find really old stock, that's different. I first noticed this in the early to mid 90s so I mean really old stock.

if you find really old stock, that's different. I first noticed this in the early to mid 90s so I mean really old stock.

I bought a pair of new crossdrilled slotted rotors for $83 last year, so it really isn't worth risking your ride on worn-out rotors.

Can you tell me where you purchased these? Did they come with the hub or did you transfer your own hub? Seem like the hub and rotor would need to be balanced as a unit. Thanks

Presumably it needs a pdf reader.

I'd avoid drilled and slotted unless there is a specific need. Spend the money on good pads.

I download and read PDF files all the time. No big deal.

Thanks

Download the Plymouth version. It has almost all the same info as the Dodge version.

If you buy a reprint, don't buy from Faxon. They have the lowest quality.

Try Bishko or just about anyone else for that matter.

I ordered from Bishko. Thanks

https://www.ebay.com/usr/brakelabs

These rotors seem very nicely machined, and a better deal than no-name stock replacements. They are zinc coated so the edges won't rust like the stock ones.

They do not come with hubs — I had them pressed on by a machine shop. I swapped in RH thread studs while I was at it.

I bought a set of similar rotors about 15 years ago that were made in USA and I was very pleased with them. No fade, no warping, handled hard braking at Willow Springs circuit. They went out of production, but then this brand showed up. I suspect they are made in China, but I don't actually know for sure.

These rotors seem very nicely machined, and a better deal than no-name stock replacements. They are zinc coated so the edges won't rust like the stock ones.

They do not come with hubs — I had them pressed on by a machine shop. I swapped in RH thread studs while I was at it.

I bought a set of similar rotors about 15 years ago that were made in USA and I was very pleased with them. No fade, no warping, handled hard braking at Willow Springs circuit. They went out of production, but then this brand showed up. I suspect they are made in China, but I don't actually know for sure.

If you have to buy new rotors, get ones where the 'hat' that goes over the hub has been machined. Every time I've checked the castings all seem to be the same - which means the as-cast hat will kiss the pistons boots every rotation.

if you find really old stock, that's different. I first noticed this in the early to mid 90s so I mean really old stock.

I agree, my new Bestop drilled rotors needed some grinding on the hat to prevent this, one side only. The ones I pulled with less than 2 years of use did not. Course they were purchased in 1988. Only changed because my braking was never right, my bad as I thought I would change it all. The rotors were never the issue. Still have them Just incase!

Last edited:

Think that's one of the brands I looked at for back up rotors.

I don't go through rotors quickly, but like to have at least a pair of fresh ones on the shelf.

The way things are now, no businesses like to have extra inventory. So even if they plan to make another run, sometimes there's a gap of months or even a couple years in availability. Here's some of the others.

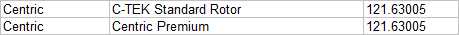

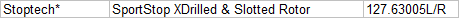

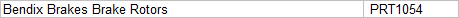

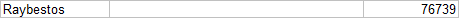

Centric 'premium' rotors should actually be 120.xxxx.

Stoptech is a brand of Centric, as is C-tek.

Same p/n as the ones I bought from NAPA and returned around 1992

Same p/n as the ones I bought from NAPA and returned around 1992

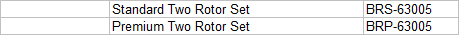

This is the vender and standard rotor. Standard BRS-63005 Brake Rotors

I guess its BrakePerfomance.com private label brand. or maybe they even do the machining themselves.

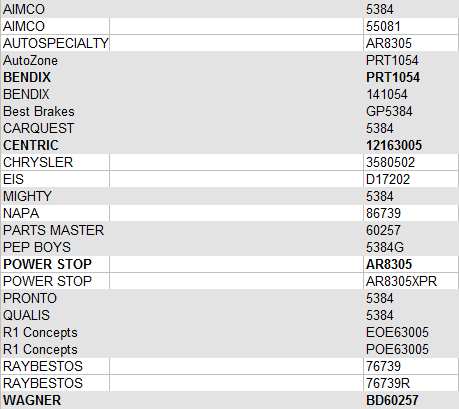

This is a cross ref list I got from a now defunct website. I can't vouch for all the numbers being correct or quality of one vs another. But it gives you p/n numbers to look for when the stupid look up table on a computer says there is no brakes, or no disk brakes for your car.

I don't go through rotors quickly, but like to have at least a pair of fresh ones on the shelf.

The way things are now, no businesses like to have extra inventory. So even if they plan to make another run, sometimes there's a gap of months or even a couple years in availability. Here's some of the others.

Centric 'premium' rotors should actually be 120.xxxx.

Stoptech is a brand of Centric, as is C-tek.

This is the vender and standard rotor. Standard BRS-63005 Brake Rotors

I guess its BrakePerfomance.com private label brand. or maybe they even do the machining themselves.

This is a cross ref list I got from a now defunct website. I can't vouch for all the numbers being correct or quality of one vs another. But it gives you p/n numbers to look for when the stupid look up table on a computer says there is no brakes, or no disk brakes for your car.

Last edited:

-