Yes. There is a car that needs some structural repair, and this is to bend some 12 gauge sheet metal. Tired of vise and hammer, and this will give me better control.This is a jig to use with a press?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your home made tools

- Thread starter fishy68

- Start date

-

Answered my question, thanks. I was wondering about lateral movement, but you addressed it during the build. Nicely done.I dont think it needs more than tacks. I have a small piece of angle iron welded under the V to prevent it from pushing apart. Its for stuff less than 1/8”

I removed the gear teeth of an old shaft then used an old distributor to turn it, but I also have the mixer shaft just don’t let it touch the bushing in block.I had and old screw driver that had a broken handle that had the correct hex welded to a piece of rod to spin the oil pump to prime the motor. I misplaced it and needed an alternative. I almost was ready to cut up my caulk gun as that would have worked, that's a good caulk gun; shame to cut it up. While at the hardware store picking up some spray paint...$6, long enough, no welding. Maybe since it's red, it will be easier to find next time I need it.

View attachment 1716152688

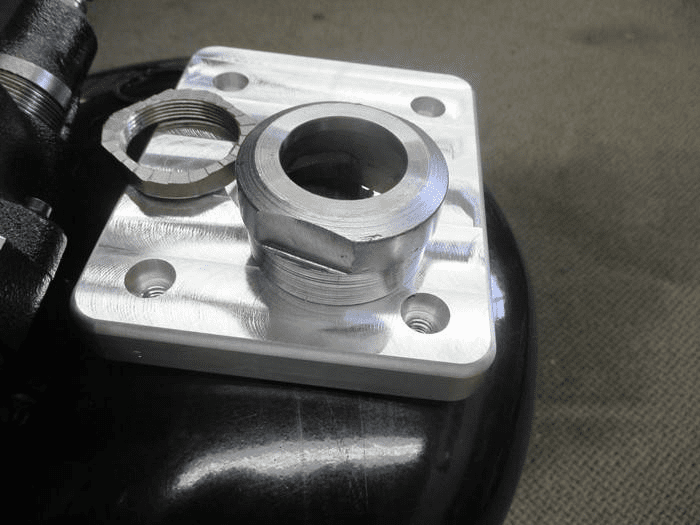

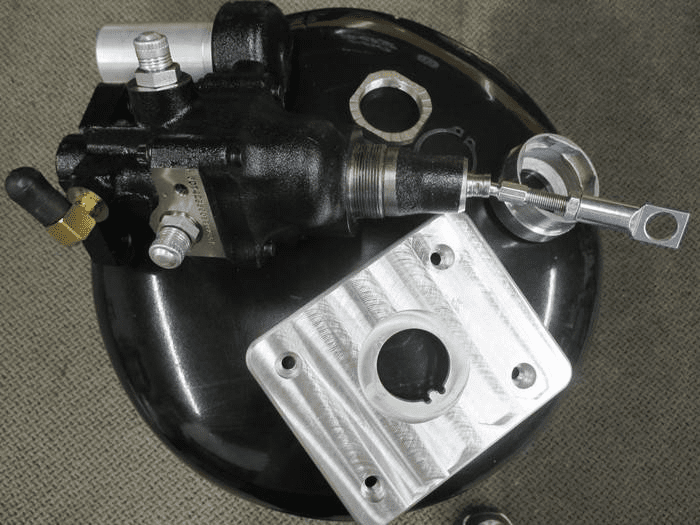

I wanted the mounting plate for my hyda-boost brakes coated[can't have raw aluminum], for I decided to take it apart. HA!.... It wasn't meant to be disassembled, and it looks like they may have had issues with one at some point[so much effort to make it not come apart]. It's assembled with a toothed nut, nuclear lock-tite, and a snap-ring just in case[plus no access with regular tools]. I had to make a socket to fit in the recess of the plate, and over the back of the hydraulic unit. We started with a 3/4-drive Proto ball-joint socket. After about an hour on the lathe and mill, I had a socket that would fit....it took a 3 foot adjustable wrench and some grunt to get it off. We did, and milled the free advertising off as I prepped the piece for powder.

Last edited:

What is it?Full of lead.. at least 70 yrs old and don’t ask me how I know..

View attachment 1716156586

View attachment 1716156587

View attachment 1716156588

Nicely done!I wanted the mounting plate for my hyda-boost brakes coated[can't have raw aluminum], for I decided to take it apart. HA!.... It wasn't meant to be disassembled, and it looks like they may have had issues with one at some point[so much effort to make it not come apart]. It's assembled with a toothed nut, nuclear lock-tite, and a snap-ring just in case[plus no access with regular tools]. I had to make a socket to fit in the recess of the plate, and over the back of the hydraulic unit. We started with a 3/4-drive Proto ball-joint socket. After about an hour on the lathe and mill, I had a socket that would fit....it took a 3 foot adjustable wrench and some grunt to get it off. We did, and milled the free advertising off as I prepped the piece for powder.

View attachment 1716156590

View attachment 1716156591

View attachment 1716156592

Pretty cool

If I trusted my welding skills lol, looks pretty slick.

Not a home made tool but a cool trick.

Cley

Not sure what to call it or what I originally made it for, but it's gotten a lot of use and a little bit shorter over the years. A long 3/8 pipe ripple and 3/8 brass cap. I use mainly for driving out races and bushings. I used the other day on some wheel bearing races.

Once the end gets buggered up I just trimm it off and carry on.

I used it a while back on some diffential bearing races, it's getting a little short and hard to grip so I'm going to make a new one for the next project

Once the end gets buggered up I just trimm it off and carry on.

I used it a while back on some diffential bearing races, it's getting a little short and hard to grip so I'm going to make a new one for the next project

Brilliant!

Brilliant!

I’ve seen this before using a short extension and power steering to drive out the bearing assembly

I made a foldable carb stand to throw in my Holley tool box. Just used stuff I had laying around. Turned out good!

Cley

Cley

Carb stand is cool.

Scamp Rhonda

Well-Known Member

It's so simple it's genius. Great idea!

That looks sturdy as heck! Aren't C clamps usually cast iron?

Nice job.

Nice job.

4$ vavle spring compressor Got the idea off of YouTube.

It could use some refining, but it works

View attachment 1716314330

Making up a rig to water the extreamly dusty road out here after over a month with no rain, and no rain in foreseeable future.

275 gallon water storage tote tank, stub trailer, and 5' boom.

Doubled the size of the boom feed pipe, and drilled out the 3/8" drain holes to 1/2" for better flow.

Here is what the road looked like last year after watering it by hand and dragging out 300 feet of 3/4" garden hose. I like the watering cart better and I can cover more distance up the road too.

They put down Calcium Chloride early in the Summer, but with no rain that does not work either. Needs some moisture to hold onto to keep the dust down.

Working pretty good all things considered, can do a 90° turn between the water cart and tow tractor for turning around (180°) in the middle of the road without having to stop and backup. Just keep on going as the water is flowing.

☆☆☆☆☆

275 gallon water storage tote tank, stub trailer, and 5' boom.

Doubled the size of the boom feed pipe, and drilled out the 3/8" drain holes to 1/2" for better flow.

Here is what the road looked like last year after watering it by hand and dragging out 300 feet of 3/4" garden hose. I like the watering cart better and I can cover more distance up the road too.

They put down Calcium Chloride early in the Summer, but with no rain that does not work either. Needs some moisture to hold onto to keep the dust down.

Working pretty good all things considered, can do a 90° turn between the water cart and tow tractor for turning around (180°) in the middle of the road without having to stop and backup. Just keep on going as the water is flowing.

☆☆☆☆☆

-