So I'm just toying with the idea of Turbo now that I missed the season and have a lot of time to go further in debt. I don't think I can afford to do a twin turbo, I have about $2000 for this, also I think a single turbo with the nitrous will be sufficient especially because too much boost puts me in cage territory which is another $2000 I don't think I can find right now. So my question is will I run into any problems with equal pressure? Do I need to split the connection to both headers? I have read quit a bit on here and my head is reeling but I figure if I can decide between 1 or 2 turbos I can start making the plan. Thanks for reading my dumb questions.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Single turbo on dual exhaust

- Thread starter Jimmy

- Start date

-

Backtobasics

Well-Known Member

I would go single. You will spend less on turbo with one good medium size, then two smaller units, plus the associate cost of plumbing hotside, cold side, and hose for oil feed and return, etc.

Many have good success joining one side into the other with good results. The variance of one side being a little longer then the other will be minimal.

A single is also more forgiving for packaging of intercooler, etc.

Can you post your basic combo?

"Nitrous to spool, and alky to cool", seems to be a decent direction, using the alky / water injection to cool the charge, and alky has the advantage of combustability, and injected water does a great job of steam cleaning combustion chambers to minimize carbon build up which can lead to detonation.

Many have good success joining one side into the other with good results. The variance of one side being a little longer then the other will be minimal.

A single is also more forgiving for packaging of intercooler, etc.

Can you post your basic combo?

"Nitrous to spool, and alky to cool", seems to be a decent direction, using the alky / water injection to cool the charge, and alky has the advantage of combustability, and injected water does a great job of steam cleaning combustion chambers to minimize carbon build up which can lead to detonation.

Backtobasics

Well-Known Member

Are you asking on dual turbos, or how to take a single turbo, and split it into dual exhaust?

If you are talking exhaust:

If you have a good dual system under there, I don't think it would be to bad to split it under the vehicle, (somewhere near trans tunnel?) to join the existing tubing.

If you are going to add exhaust afterwards, a sizeable single system will keep velocity, and you could probably go single in - dual out on the muffler, and have dual tailpipes run, if you are looking for the "dual exhaust" look on the back of the car.

If you are talking exhaust:

If you have a good dual system under there, I don't think it would be to bad to split it under the vehicle, (somewhere near trans tunnel?) to join the existing tubing.

If you are going to add exhaust afterwards, a sizeable single system will keep velocity, and you could probably go single in - dual out on the muffler, and have dual tailpipes run, if you are looking for the "dual exhaust" look on the back of the car.

Dusterdude72

IN MOPAR MUSCLE MAGAZINE

just another option you could do.

come off the headers into a Y pipe.....where it is single pipe you could run your turbo to and after that you could split back off into duals.

I am probably not the best guy for info on this though as I have no clue about anything to do with forced induction really lol.

but a suggestion none the less

come off the headers into a Y pipe.....where it is single pipe you could run your turbo to and after that you could split back off into duals.

I am probably not the best guy for info on this though as I have no clue about anything to do with forced induction really lol.

but a suggestion none the less

don't worry Duster I'm not sure about any of this, even after reading countless articles and how to posts for the last 4 days I still have no clue. Basically I was thinking what your thinking but it seems like it should be easier some how.

B2B Basically this all started because I was about to buy a TQ-Cam-Carb-Head combo for the 318 I have in the car or the 360 I have sitting beside it. When I found out I could take the J heads off the 360 and put them on the 318 with bigger valves and then be rewarded for the low compression by turbocharging I jumped on board, I don't need 1000hp but 500 - 600 would be great (first hit free?). It has msd digital 6, 150 shot No2, a ld4b, afb, hookers & 904 w/ 2100 converter and stock gears, 27" x 9" rear 26" x 7" I'm thinking 2800 stall and 3.9 gears a Mighty demon BC 650, a (insert your recommendation) Turbo, Whatever cam comp cams tells me to get with this combo, stock bottom end and the J heads with 2.2 valves. But I just came up with this stupid idea so I'm not sure about anything. It's just a track toy and I haven't made it there yet so I'm not looking for a cage, loop, parachute wheelie machine

B2B Basically this all started because I was about to buy a TQ-Cam-Carb-Head combo for the 318 I have in the car or the 360 I have sitting beside it. When I found out I could take the J heads off the 360 and put them on the 318 with bigger valves and then be rewarded for the low compression by turbocharging I jumped on board, I don't need 1000hp but 500 - 600 would be great (first hit free?). It has msd digital 6, 150 shot No2, a ld4b, afb, hookers & 904 w/ 2100 converter and stock gears, 27" x 9" rear 26" x 7" I'm thinking 2800 stall and 3.9 gears a Mighty demon BC 650, a (insert your recommendation) Turbo, Whatever cam comp cams tells me to get with this combo, stock bottom end and the J heads with 2.2 valves. But I just came up with this stupid idea so I'm not sure about anything. It's just a track toy and I haven't made it there yet so I'm not looking for a cage, loop, parachute wheelie machine

I think you should spool the turbo from both sides of the engine. (exhaust)

You can split back into duals after the turbo if you prefer that.

You can split back into duals after the turbo if you prefer that.

Backtobasics

Well-Known Member

So just to make sure I have it right this is what I think I have to do...

The diagram you provided will work. In reality, the down pipe will probably come down on the passenger side, and any number of vendors make a good Y pip, that will allow you to smooth and with minimal flow interruption, divert 1/2 of the exhaust over to the driver side.

Dusterdude72

IN MOPAR MUSCLE MAGAZINE

So I just have to get this straight

Step 1.

Dual exhaust connected near collectors to "Y Pipe" and fed to Turbine only, not spliced.

Step 2.

Turbine exhaust connected to "Y Pipe" and fed back to dual exhaust meaning that ALL exhaust would pass through Turbine

Step 3.

Figure out the Compressor and inter cooler

Step 4.

Go fast

I cant just tap the exhaust system as in Dusters and my incredible diagrams? the system has to be fed through the Turbine only and it must be equal. Correct?

Step 1.

Dual exhaust connected near collectors to "Y Pipe" and fed to Turbine only, not spliced.

Step 2.

Turbine exhaust connected to "Y Pipe" and fed back to dual exhaust meaning that ALL exhaust would pass through Turbine

Step 3.

Figure out the Compressor and inter cooler

Step 4.

Go fast

I cant just tap the exhaust system as in Dusters and my incredible diagrams? the system has to be fed through the Turbine only and it must be equal. Correct?

turbodart68

Well-Known Member

The exhaust will need to leave the engine through the heders/manifolds into a single pipe that will go to the turbine inlet through the turbo and out a single pipe and then split in two and reconnect to your existing system. Just like the old picture you posted. I would use the shorty headers like Maddart used and then use a T04 turbo and give it 10-15 pounds of boost and meth injection to intercool and raise octane levels. This combo on a 318 would yield low 11s in an abody. I actually had this very set up on a car before and it was killer.

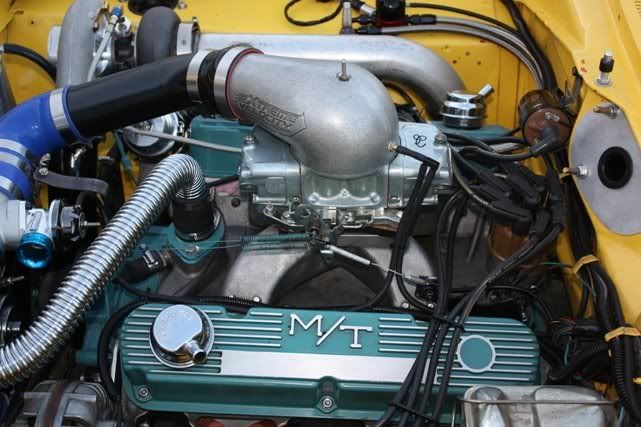

Now that's how ya do it!

What you have pictured will work great.

I'm still not sure how to close the loop, did you mean bring it back to the drivers side or just another y at the turbo or something like this?

What you have pictured will work great.

PanGasket

has cork sides

MMMM, That couldnt look better unless I was dreaming:-Dall that mumbo jumbo up there is not clear.....

Look at this:

it doesnt get much clearer than that.

:cheers:

8)

all that mumbo jumbo up there is not clear.....

Look at this:

[email protected]

it doesnt get much clearer than that.

:cheers:

8)

The exhaust will need to leave the engine through the heders/manifolds into a single pipe that will go to the turbine inlet through the turbo and out a single pipe and then split in two and reconnect to your existing system. Just like the old picture you posted. I would use the shorty headers like Maddart used and then use a T04 turbo and give it 10-15 pounds of boost and meth injection to intercool and raise octane levels. This combo on a 318 would yield low 11s in an abody. I actually had this very set up on a car before and it was killer.

Now that's how ya do it!

What you have pictured will work great.

Thanks for clearing it up for me, I'm now getting the whole concept a little clearer thanks to all of your help so thank you all. Now if only I could learn to weld pipe like that I'm good to go, have a Garret .52A/R cold .82A/R hot and a Mighty Demon BC, hat, a couple y pipes and bends, a boost ref regulator, all I need now is a new fuel pump, intercooler, waste gate, bov, oil return, shorty headers, heat shields, boost controller, meth injection, guage....... holy heck when does it end?

Backtobasics

Well-Known Member

Sorry, I have been out of the loop, but it appears others are chiming in.

Prine's diagram is spot on, the only difference is the down pipe after the turbo would go under the car, and using the Y pipe I pictured above, would split from the one single down pipe into 2 pipes, to join the existing dual exhaust.

The picture you posted in post #10 is exactly what I have in mind. Where the exhaust crosses over to join the drivers side is up to you, but you are on track.

The beauty if it is all the tubing can be done in mild steel, and can be built with (relatively) inexpensive mandrel bends, chop saw or sawzall, and tacked or finished welded with a (relatively) inexpensive mig welder.

Prine's diagram is spot on, the only difference is the down pipe after the turbo would go under the car, and using the Y pipe I pictured above, would split from the one single down pipe into 2 pipes, to join the existing dual exhaust.

The picture you posted in post #10 is exactly what I have in mind. Where the exhaust crosses over to join the drivers side is up to you, but you are on track.

The beauty if it is all the tubing can be done in mild steel, and can be built with (relatively) inexpensive mandrel bends, chop saw or sawzall, and tacked or finished welded with a (relatively) inexpensive mig welder.

I think Im' getting it, asking this question forced me understand the entire process which is good. On the steel side of things I was under the impression I had to use stainless can I get away with aluminumised (sp?) or should I just use stainless for the up and down and then standard for everything else? Also the headers are 3" collector so going to reduce to 2.5 then y back to a 4" for the up then have a 4" down all the way to the axles then then split to the dual 2 1/4" do you think that will flow or should I just do 3 up 3 down single exhaust to a twin tip coming out the center back (Like a Porsche)?

Sorry, I have been out of the loop, but it appears others are chiming in.

Prine's diagram is spot on, the only difference is the down pipe after the turbo would go under the car, and using the Y pipe I pictured above, would split from the one single down pipe into 2 pipes, to join the existing dual exhaust.

The picture you posted in post #10 is exactly what I have in mind. Where the exhaust crosses over to join the drivers side is up to you, but you are on track.

The beauty if it is all the tubing can be done in mild steel, and can be built with (relatively) inexpensive mandrel bends, chop saw or sawzall, and tacked or finished welded with a (relatively) inexpensive mig welder.

-