66Dvert

Working on my custom car parts again!

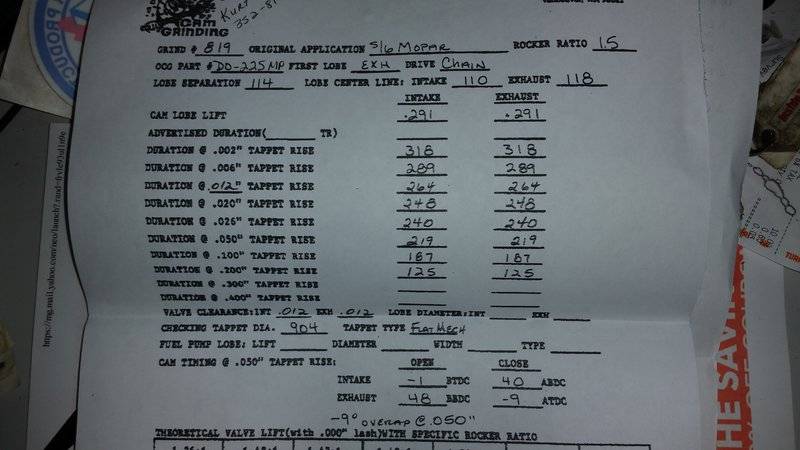

Yahoo! just got the reground cam in and new lifters. moving forwards (slowly but moving)

Last edited:

Yahoo! just got the reground cam in and new lifters. moving forwards (slowly but moving)

View attachment 1714986175

66Dvert,

How much was the cam and how long did it take them to make it?

Any news on your build?

Mike

Hi Charlie,What machine shop did you wind up using?

total cost for cam regrind, fixing the worn fuel pump lobe, shipping from there and new lifters was $192.00. Shipping to there was 26.00 (Ken Heard from Oregon cams said not to put in a PVC pipe since he has seen quite a few broken that way) I used a 3 corner box from the post office and packed it well with bubble wrap.

total time was 2 weeks from sendoff to delivery.

block is in the shop now and it looks like a .030 minimum cleanup. I'm still waiting on final determination due to the holidays and he's pretty busy.

getting Cam bearings and crank checked/polished or turned depending on wear. so I'm in holding pattern right now. I'm making new molds for my kick panels and trying to get the convertible arm rests into a usable state right now.

YoungDart75 I'll have to finalize my block/head combo and static compression before I even think about the correct turbo. I'll be sure to pm you guys for info after I get the compression ration nailed down. Thanks

Just got the head back from the machine shop. 1.44 and 1.70 valves hardened exhaust and some small amount of porting started .030 off the head to even things up and it'll be CC'd this weekend. I'll do the rest by just smoothing in the bowls and rough spots. Block and crank just got dropped off for new cam bearings, boring to cleanup for new pistons and crank checked to see if it needs ground undersize. Cam is @ oregon grinders getting an #819 @ 114 separation for the turbo setup. I'm getting closer! where can I find a new heater hose nipple that goes into the head since mine is really nasty?

View attachment 1714982827

View attachment 1714982828