Hey the peeps.

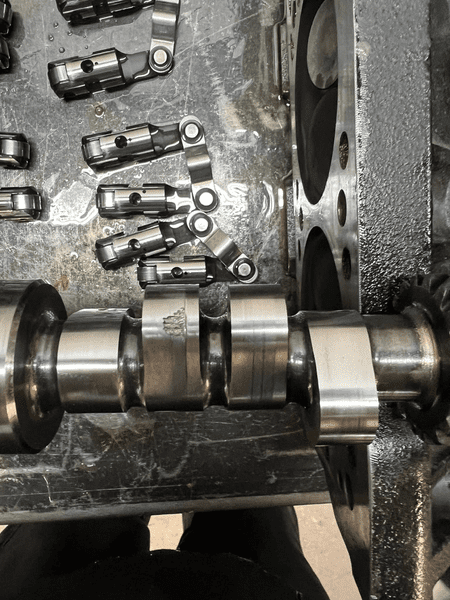

Have a set o BAM solid roller lifters in my SBM with .180"offset pushrod hole on the intake.

Recently damaged 2 intake lobes and the other 6 intake lobes have the same witness/wear marks.

Was wondering if the pushrod offset could be causing this issue.

Has anyone use offset lifters and had issues.

Thx.

Have a set o BAM solid roller lifters in my SBM with .180"offset pushrod hole on the intake.

Recently damaged 2 intake lobes and the other 6 intake lobes have the same witness/wear marks.

Was wondering if the pushrod offset could be causing this issue.

Has anyone use offset lifters and had issues.

Thx.