So I was having some recent shifting issues with my 904 on 5.9 Magnum combo. Occasional 1-2 flare when getting on it and having to back off throttle to get 3rd. Only about 50 miles like this. Normal driving OK. I dropped the pan and had some wear sludge in it. Pulled the filter and the kickdown band strut bar dropped out. Apparently it was way out of adjustment. Still some meat on the front band so I dropped the valve body and got the strut bar back in place and adjusted. Before you say it.......the transmission is going to come out but just not right now. The issue now is the fluid in the converter. I have a 340 2400 stall converter from Torqueflite Patty (RIP) with a drain plug however I am running a factory Magnum flex plate and the drain plug I believe is blocked. Thought about drilling a hole via the inspection cover but worried about a balance issue and debris. Any thoughts on this besides top off with type F and hope for the best? Pan is currently off.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solve the puzzle? Draining converter with Magnum flex plate

- Thread starter JoePole1

- Start date

-

Take out the starter.

Rotate the tq till you can see the drain plug.

Remove the drain plug, have a magnet on a stick on hand.

Rotate converter till drain plug is down.

Reverse the process and clean up the mess.

You might want to get some paint thinner and an appropriate pump to flush out the bell housing of residual trans fluid.

Dont know if this is a good idea or not...

I have had good success with a submersible fountain pump in a catch pan and a gallon of paint thinner and a flexible tube.

Rotate the tq till you can see the drain plug.

Remove the drain plug, have a magnet on a stick on hand.

Rotate converter till drain plug is down.

Reverse the process and clean up the mess.

You might want to get some paint thinner and an appropriate pump to flush out the bell housing of residual trans fluid.

Dont know if this is a good idea or not...

I have had good success with a submersible fountain pump in a catch pan and a gallon of paint thinner and a flexible tube.

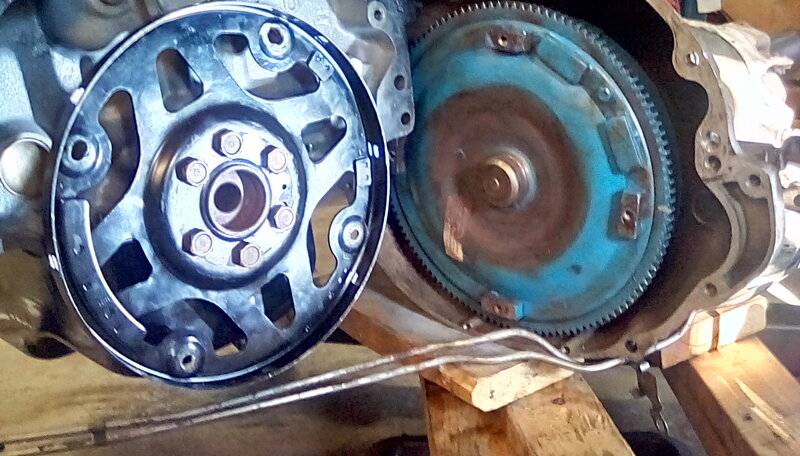

The stuff in the picture, Was this used as a pair? or is it just stuff? Where's the alignment dowel for the block? If you need to have that drain plug accessible and balance weight is an issue, then make 2 holes opposite to each other, as in 180* apart.

Genius. I knew I could count on you guys. Thanks Dana67!!!Take out the starter.

Rotate the tq till you can see the drain plug.

Remove the drain plug, have a magnet on a stick on hand.

Rotate converter till drain plug is down.

Reverse the process and clean up the mess.

You might want to get some paint thinner and an appropriate pump to flush out the bell housing of residual trans fluid.

Dont know if this is a good idea or not...

I have had good success with a submersible fountain pump in a catch pan and a gallon of paint thinner and a flexible tube.

Can always do the transfusion thing dropping one of the trans cooler lines to flush the converter out.

One gallon out > one gallon back in, Repeat.

☆☆☆☆☆

One gallon out > one gallon back in, Repeat.

☆☆☆☆☆

Looks like the starter removal will not help. The problem is that the flex plate blocks the drain plug. See picture.

I dont think it's a good idea to drill the flex plate. Would be difficult to find 180 degrees for second hole for balance plus debris. Then there is refilling the converter after although I could then partially fill through the starter location. How does the rest get filled? Cycling, top off, repeat?

If I did use the trans cooler lines, does it go in from one and then out the other? I don't understand how the fluid path flows through the transmission and converter. Couldn't it follow path of least resistance and bypass the converter at least partially?

I dont think it's a good idea to drill the flex plate. Would be difficult to find 180 degrees for second hole for balance plus debris. Then there is refilling the converter after although I could then partially fill through the starter location. How does the rest get filled? Cycling, top off, repeat?

If I did use the trans cooler lines, does it go in from one and then out the other? I don't understand how the fluid path flows through the transmission and converter. Couldn't it follow path of least resistance and bypass the converter at least partially?

JDMopar

Well-Known Member

No help on the drain plug, but if you are using that converter on a 5.9 Magnum, you need to remove the weights from the converter. The 5.9 Magnum has weights on it for the balance of the motor, so none are needed on a converter. It would shake your teeth out using both....lol.

Thanks for the watchful eye. Those pics were before I installed the transmission. Converter weights were removed and flex plate installed in the correct orientation. I believe it was backwards in that picture. Been on the road for a couple of years now. All good.No help on the drain plug, but if you are using that converter on a 5.9 Magnum, you need to remove the weights from the converter. The 5.9 Magnum has weights on it for the balance of the motor, so none are needed on a converter. It would shake your teeth out using both....lol.

JDMopar

Well-Known Member

Great! Just didn't want you to have extra work on top of the drain plug worries. I wonder if you were to remove the converter to flex plate bolts, then push the converter back into the trans as far as it will go, could you get a wrench on that drain plug? That may not work because of the lip around the edge of the flex plate, but it may be worth a look to see. You can't cut an access slot in the lip to make it work though, because it would screw up the balance. Since the 904 is coming out later, I believe I would just top it off and run it since the pan just had normal wear sludge and no chunks.

Looks like the starter removal will not help. The problem is that the flex plate blocks the drain plug. See picture.

I dont think it's a good idea to drill the flex plate. Would be difficult to find 180 degrees for second hole for balance plus debris. Then there is refilling the converter after although I could then partially fill through the starter location. How does the rest get filled? Cycling, top off, repeat?

If I did use the trans cooler lines, does it go in from one and then out the other? I don't understand how the fluid path flows through the transmission and converter. Couldn't it follow path of least resistance and bypass the converter at least partially?

With the trans filter back on and the pan back on and 4 quarts of new trans fluid back in the pan.

Put a "T" with a 10" long rubber down hose on it and plumb that in on the passenger side trans cooler line before it enters the radiator.

Put the 10" long rubber down tube into a 1 gallon old plastic milk jug, with the jug sitting in an oil drain pan.

Now start up the engine and when the milk jug is half full of trans fluid, shut the engine off. Then put 2 new quarts of trans fluid in to replace what just came out. Repeat until the trans fluid coming out of the "T" is clean.

Tip: You can plug the T line down hose, after running a fresh gallon of trans fluid through the trans then fill the trans to the proper fluid level. If the trans fluid still looks dirty, keep flushing it out 2 quarts at a time till running clean.

Start > pump out 2 quarts, shut off > put in 2 new quarts trans fluid to replace what just came out. Repeat as needed until you are satisfied the converter has been flushed clean.

Remove the "T" and down hose, reconnect the trans cooler line to the radiator.

Top off the trans to the proper fluid level, idling in neutral for the 727.

And yes remove the balance weights on the 727 torque converter if they are on there, make it neutral balance. The the Magnum flex plate already has the proper weight added for the external balanced Magnum engine.

☆☆☆☆☆

Excellent. This sounds do-able. Thanks to all for your suggestions. Much appreciated! Will follow up with results.With the trans filter back on and the pan back on and 4 quarts of new trans fluid back in the pan.

Put a "T" with a 10" long rubber down hose on it and plumb that in on the passenger side trans cooler line before it enters the radiator.

Put the 10" long rubber down tube into a 1 gallon old plastic milk jug, with the jug sitting in an oil drain pan.

Now start up the engine and when the milk jug is half full of trans fluid, shut the engine off. Then put 2 new quarts of trans fluid in to replace what just came out. Repeat until the trans fluid coming out of the "T" is clean.

Tip: You can plug the T line down hose, after running a fresh gallon of trans fluid through the trans then fill the trans to the proper fluid level. If the trans fluid still looks dirty, keep flushing it out 2 quarts at a time till running clean.

Start > pump out 2 quarts, shut off > put in 2 new quarts trans fluid to replace what just came out. Repeat as needed until you are satisfied the converter has been flushed clean.

Remove the "T" and down hose, reconnect the trans cooler line to the radiator.

Top off the trans to the proper fluid level, idling in neutral for the 727.

And yes remove the balance weights on the 727 torque converter if they are on there, make it neutral balance. The the Magnum flex plate already has the proper weight added for the external balanced Magnum engine.

☆☆☆☆☆

Might be cheaper to have a trans flush done at a service stationExcellent. This sounds do-able. Thanks to all for your suggestions. Much appreciated! Will follow up with results

Following up....since I had the pan off and the fluid was so cooked, I decided to pull the valve body and do a better inspection. Turns out the front band is toast. No material left on it. Rear band doesn't look much better. Not sure why both were so far out of adjustment. Gotta come out. I found an A999 "in good condition" to swap in to get me by until this winter when I can get my 42RH built and installed. Fingers crossed on the A999. Anyway....I found a pretty good video on a full system flush. Won't do me any good but maybe for someone else down the road. It's pretty much what George Jets described. Cheers.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 25,875

- Reaction score

- 13,184

Just so you know, moot now,

I have drilled and tapped a few 904 convertors, with no noticeable balance effects; but then, the stock 318LAs only rev to barely 5000 when the valves begin to float. Mine had better springs and went to 5500 but the cam was done by 4500 or so. I just reved it to 5500 cuz she went there lol.

I have drilled and tapped a few 904 convertors, with no noticeable balance effects; but then, the stock 318LAs only rev to barely 5000 when the valves begin to float. Mine had better springs and went to 5500 but the cam was done by 4500 or so. I just reved it to 5500 cuz she went there lol.

Thanks AJ. My converter has a drain. I just can't get to it because the Magnum Flexplate blocks access.Just so you know, moot now,

I have drilled and tapped a few 904 convertors, with no noticeable balance effects; but then, the stock 318LAs only rev to barely 5000 when the valves begin to float. Mine had better springs and went to 5500 but the cam was done by 4500 or so. I just reved it to 5500 cuz she went there lol.

-