You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some TrickFlow curiosity work

- Thread starter pittsburghracer

- Start date

-

[email protected] lift?

I don’t think so.

I don’t think he could hit that at .100 with the spark plug out. Lol

67autocross

A new iron curtain drawn across the 49th parallel

It’s a stock trick flow head… I give it to the guy with the valve springs pulled on 2 ports and said give it a quick pull

Gotcha. Not that it matters, but he got the valve sizes wrong.It’s a stock trick flow head… I give it to the guy with the valve springs pulled on 2 ports and said give it a quick pull

You're gonna want a steeper top cut eventually.....Also too much chatter for my liking, finish with a stone. J.Rob

I wanted to address this a little better today. On these heads I plan on either changing seats and or keeping this head or seat of heads for testing purposes. I never cut seat on my seat machine if I am going with a bigger valve because the cutter will and does hit the chamber. Especially when using my favorite 4 angle cutter. At least on the Speedmaster heads the have a slight cut that is made cutting their seat. I wasn’t up to getting in my porting coveralls so I was just experimenting. Here a picture of a Speedmaster head before I do my chamber work for the 2.055 valve these are getting. Love to show an after shot but it usually bites me in the butt and it opens a can of worms an comments I’d rather not be faced with. But yes you do get chatter on most seat machines so the seat angle get dressed and vacuum tested.

I wanted to address this a little better today. On these heads I plan on either changing seats and or keeping this head or seat of heads for testing purposes. I never cut seat on my seat machine if I am going with a bigger valve because the cutter will and does hit the chamber. Especially when using my favorite 4 angle cutter. At least on the Speedmaster heads the have a slight cut that is made cutting their seat. I wasn’t up to getting in my porting coveralls so I was just experimenting. Here a picture of a Speedmaster head before I do my chamber work for the 2.055 valve these are getting. Love to show an after shot but it usually bites me in the butt and it opens a can of worms an comments I’d rather not be faced with. But yes you do get chatter on most seat machines so the seat angle get dressed and vacuum tested.

View attachment 1716230638

View attachment 1716230639

I think you can imagine how a 2.055 and especially a 2.08 cutter would hitting the chamber cause chatter

RAMM

Well-Known Member

I don't have chatter problems when cutting but rigidity is of the utmost importance. The machine you are using and it's column design/fixturing and spindle size needs to be as short/stocky and as large as possible. Then there's the tooling and cutter geometry. You absolutely need carbide pilots and the correct rake on sharp blades. Then there's the speed/feed and operator touch....All factors need to line up. Contact with the chamber is nothing more than the extended top cut and is not the source of chatter IME. J.RobI think you can imagine how a 2.055 and especially a 2.08 cutter would hitting the chamber cause chatter

I don't have chatter problems when cutting but rigidity is of the utmost importance. The machine you are using and it's column design/fixturing and spindle size needs to be as short/stocky and as large as possible. Then there's the tooling and cutter geometry. You absolutely need carbide pilots and the correct rake on sharp blades. Then there's the speed/feed and operator touch....All factors need to line up. Contact with the chamber is nothing more than the extended top cut and is not the source of chatter IME. J.Rob

I wish you would share some tech once in awhile instead of just criticizing someone else that is sharing info. That would be a pleasant surprise. I guess it’s time for me to take another break from here for awhile. Thanks.

RAMM

Well-Known Member

I see ZERO criticism in my post and ironically it WAS filled with valuable tech. Speaking of sharing tech-- I have shared tech (info) umm, literally hundreds if not thousands of times. Sorry for hurting your feelings. J.RobI wish you would share some tech once in awhile instead of just criticizing someone else that is sharing info. That would be a pleasant surprise. I guess it’s time for me to take another break from here for awhile. Thanks.

P.S. I was "sharing" what I went through battling chatter and was speaking from experience. Upgrading to $240 per carbide pilots was probably the single best move. Cutting which is actually glorified scraping that many angles with that much surface contact is basically impossible. Why do you think they built the Contour machining center? Single point with a radius tipped insert is the only way to fly. If I had the $$$$$ I'd have one.

Last edited:

I see ZERO criticism in my post and ironically it WAS filled with valuable tech. Speaking of sharing tech-- I have shared tech (info) umm, literally hundreds if not thousands of times. Sorry for hurting your feelings. J.Rob

Not hurt just tired of explaining things so sometimes it’s just better taking a little step away. Like I said I haven’t been feeling great so on a non productive day I made a couple fast cuts on parts that are getting switched out. I mainly wanted to see where each cutter ended up on such a small valve seat. I call It experimenting or playing around. I shared something I shouldn’t have so I’ll better critique my own work before putting it out there. This site kinda gets let’s say stale or slow once in awhile unless you are following the multitude of 318 posts. So I’ll try to start a discussion on what if to get guys involved.

RAMM said:

I see ZERO criticism in my post and ironically it WAS filled with valuable tech. Speaking of sharing tech-- I have shared tech (info) umm, literally hundreds if not thousands of times. Sorry for hurting your feelings. J.Rob

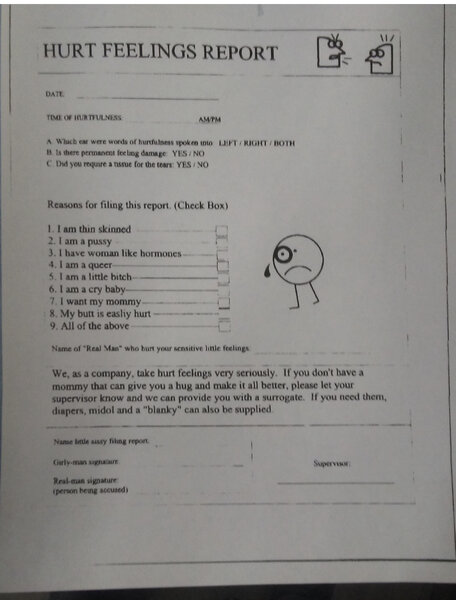

Thanks a lot Ramm. I got this report in the mail today that I have to fill out and sent in to the waaaa police.

I see ZERO criticism in my post and ironically it WAS filled with valuable tech. Speaking of sharing tech-- I have shared tech (info) umm, literally hundreds if not thousands of times. Sorry for hurting your feelings. J.Rob

Thanks a lot Ramm. I got this report in the mail today that I have to fill out and sent in to the waaaa police.

PRH

Well-Known Member

So, fill out the form…….. and get to grinding on that TF head.

Every HR department across the country should have that form.

Every HR department across the country should have that form.

My buddy Tim loves me and couldn’t wait to send that to me. He was spitting coffee reading this post. We have some pretty good discussions about some of these posts. Lol

Tim? Do I know him?

Tim? Do I know him?

No he’s famous east of the Mississippi. He’s an instigator. Lol. He likes to jab me because I make fun of his flip phone and 30 year old laptop

-