Looks like someone is stepping up

Their game.

Their game.

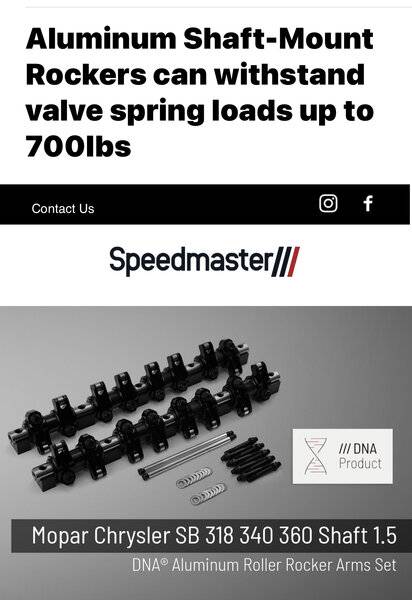

Can't find the small block version but Jeg's shows the big block Mopar for $320. If the durability and quality are there, seems like a hell of a deal.

You posted them up, I figured you joined the Speedmaster sales team.IF being the million dollar word here. I think I’ll stick with Harland Sharp and T&D.

I'm thinking he fat-fingered DNA rockers, which is the marketing name Speedmaster gave them.I have not heard of SNA Rockers?

I have about 70k+ miles on my "2nd hand" Harland Sharp rockers.IF being the million dollar word here. I think I’ll stick with Harland Sharp and T&D.

I really want to try these out... especially since all of their SS rockers seem to be out of stock still... for months. And I am too cheap to pay a million bucks for rockers... Would I need different push rods? Plus, apparently, my rocker shafts have been on incorrectly for the past million years...

You posted them up, I figured you joined the Speedmaster sales team.

You want us to try them ? and you're not. lol

I like using a bushed rocker myself.

@pittsburghracer I am glad you show everyone whats available. I currently have a larger budget to work with but I am cheap as ****, so I still live within my "I'm poor mentality." I almost bought these last night, but I am going to wait until black friday to purchase them. Unless the SS ones come back it in stock before then.

I have two sets of rockers to go with my little 383 stroker small block. The set currently on the engine are W2 Norris stainless steel rollers. I also was given a set of MP aluminum W2 rockers with my spare 365 small block engine that I purchased last September. I though about putting the MPs on my 383 but they just look and feel so flimsy compared to the Norris rockers.

One problem that I was having towards the end of last season was issues with some adjusters getting loose on the Norris rockers causing some pushrod issues. Thankfully it never caused any serious problems but only because I got lucky and dodged some bullets. I racked my brain trying to figure out why these adjusters were working their way loose, and it was almost always the #1 and #6 intake rockers. I tried different adjusters and always made sure the lock nut was tight but after a few runs one or both would be loose again. Now I'm thinking it may be due to my pushrods being too short.

So my question is, does anyone have experience using the old Norris stainless rollers and the MP aluminum W2 rockers? The Norris rockers look bullet proof to me, and as I stated earlier the MP aluminum rockers appear flimsy and weak by comparison. Also, could short push rods cause the adjuster problem? I'm out of ideas.

I have Smith Brothers 3/8 pushrods with a cup at the rocker end. I'm far from a math wiz so I’m a little confused by your calculations but I clearly understand your .050 - .060 longer intake pushrods. Sounds like I’ll be making a call to Smith Brothers. I appreciate the information!Your pushrods are not strong enough. Any time you can’t keep the adjuster tight the first thing I look at is the pushrods. IMO they need to be at a minimum 7/16-3/8 single taper. 3/8-7/16 double taper would be even better.

Norris rockers have the same oil hole clocking that Chrysler uses. That means the adjuster needs to be 9/32 out (thats ~.287) plus .050 minus zero. You don’t have much room and to do it right the intake pushrods need to be .050-.060 longer than the exhaust pushrods because of the offset.

Every pushrod manufacturer in the country will tell you their 3/8 thick wall dong beater pushrod is more than good enough and they are all wrong.

Can you put your calculations on the adjusters into layman’s terms? I’ve heard the starting point on adjusters is about 1 1/2 threads showing on the pushrod side prior to setting lash. Is that right?Your pushrods are not strong enough. Any time you can’t keep the adjuster tight the first thing I look at is the pushrods. IMO they need to be at a minimum 7/16-3/8 single taper. 3/8-7/16 double taper would be even better.

Norris rockers have the same oil hole clocking that Chrysler uses. That means the adjuster needs to be 9/32 out (thats ~.287) plus .050 minus zero. You don’t have much room and to do it right the intake pushrods need to be .050-.060 longer than the exhaust pushrods because of the offset.

Every pushrod manufacturer in the country will tell you their 3/8 thick wall dong beater pushrod is more than good enough and they are all wrong.

Can you put your calculations on the adjusters into layman’s terms? I’ve heard the starting point on adjusters is about 1 1/2 threads showing on the pushrod side prior to setting lash. Is that right?

I have Smith Brothers 3/8 pushrods with a cup at the rocker end. I'm far from a math wiz so I’m a little confused by your calculations but I clearly understand your .050 - .060 longer intake pushrods. Sounds like I’ll be making a call to Smith Brothers. I appreciate the information!

Thank you!Yeah, they will tell you that 3/8 pushrod is enough. It’s not. I’ll see if I have some double taper pushrods out there and take a picture. I know I have some single taper stuff.