You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steering shaft pin

- Thread starter nodemon

- Start date

-

Professor Fate

Push the button, Max...

Should go either way, but drive it out in the direction that it's already protruding.

Soak the splines with penetrant and use a pickle fork to work the coupler off the splines.

Soak the splines with penetrant and use a pickle fork to work the coupler off the splines.

junkyardhero

Well-Known Member

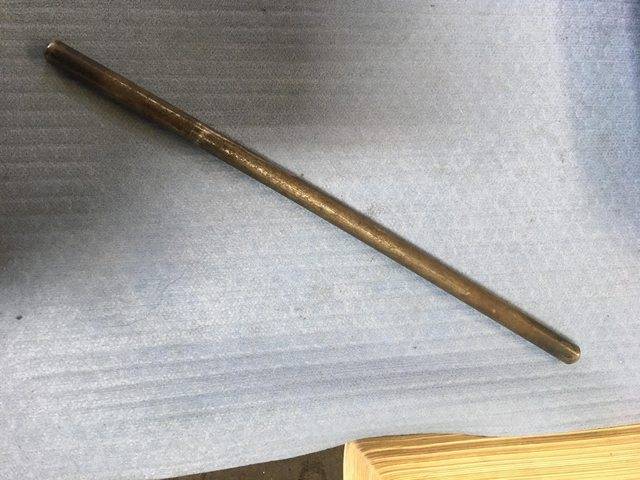

make sure you have a custom pin drift! it goes so much easier!

Push rod..??make sure you have a custom pin drift! it goes so much easier!

View attachment 1716063351

junkyardhero

Well-Known Member

correct.Push rod..??

i like using one that is closely linked to some type of costly or catastrophic failure. really brings those memories back and reminds me of crushing defeat.

I think it should be pressed out. If you are using a drift punch, support the input shaft of the steering box so you don't side load it with the hammer whacks.

Use the correct tool for the job.

Your first photo (green circle) looks like the pin has been damaged.

Your first photo (green circle) looks like the pin has been damaged.

The pin is 5/16. Make sure your punch is slightly smaller than that. Many get lulled into using a larger punch and then can't figure out why it won't work. The hole is counter-bored oversize for the first 10th of an inch or so so the split pin can get started

Demonic

Well-Known Member

Pin punches are one of those things that need to be good quality, and a good assortment. Once you have nice ones, you won't regret the purchase. Good advise above - penetrating oil, start on the side that's not goofed up.

I agree in using a press of sorts.

I started CAD to make one, just need someone with machineing abilities to make it.

It's pretty simple, a bolt on doughnet clamp with a threaded rod that has a rollpin punch on the end.

Tighten the threaded rod and the roll pin comes right out. No hammering needed.

I started CAD to make one, just need someone with machineing abilities to make it.

It's pretty simple, a bolt on doughnet clamp with a threaded rod that has a rollpin punch on the end.

Tighten the threaded rod and the roll pin comes right out. No hammering needed.

junkyardhero

Well-Known Member

i've used a big C-clamp with a deep socket on one side and short punch. also used a motorcycle valve spring compressor that worked a treat too.I agree in using a press of sorts.

I started CAD to make one, just need someone with machineing abilities to make it.

It's pretty simple, a bolt on doughnet clamp with a threaded rod that has a rollpin punch on the end.

Tighten the threaded rod and the roll pin comes right out. No hammering needed.

but i agree, something to support the assembly and not put force on the steering input is critical.

like all things in life, a positive out come is a product of heat, lube, pressure and angle of attack.

It's just a split pin. There is zero reason to be pressing it out.

Actually it is a tension pin, split pin is what we call a cotter key or cotter pin.

Wanna get technical it's a roll pin... still no reason to press it out.

ACME SS

Well-Known Member

Thank you! It does not come out that hard that it would damage the gear box. I think we get a little too nuts on here at times. Mine tapped out...not pounded out, tapped out and tapped back in.It's just a split pin. There is zero reason to be pressing it out.

jomoper

Mope or Nope

Since I didn’t see where anyone else mentioned it . I’ll say it. Use a good,new,roll pin since the original is all boogered up. It’s your steering after all!

72smallairparticler

Well-Known Member

correct.

i like using one that is closely linked to some type of costly or catastrophic failure. really brings those memories back and reminds me of crushing defeat.

I used a spare pushrod to do this and it worked amazing! Now if I could actually get the gear and coupler to come apart!make sure you have a custom pin drift! it goes so much easier!

View attachment 1716063351

junkyardhero

Well-Known Member

a little lube and some taps with a smol hammer usually does the trick.I used a spare pushrod to do this and it worked amazing! Now if I could actually get the gear and coupler to come apart!

i have to ask, though, you've got the steering column loose so that it can slide up and off the box correct?

72smallairparticler

Well-Known Member

Yep! Finally got it off with a picklefork and some strong hits. Its definitely been on there for 50 years.a little lube and some taps with a smol hammer usually does the trick.

i have to ask, though, you've got the steering column loose so that it can slide up and off the box correct?

I had every bolt off the column and it was super loose and moving about 3" when tryign to pull it up off the steering box and wouldn't budge. Finally got it with some pickefork smacks

340six

Well-Known Member

- Joined

- Jan 4, 2009

- Messages

- 1,193

- Reaction score

- 1,644

I worked with a guy from San Diego, Ca. who needed one. He drank some beers, rolled a joint, later cut one of the beer cans up and rolled one out of the beer can material.Wanna get technical it's a roll pin... still no reason to press it out.

This ^^^^ is what I do.Should go either way, but drive it out in the direction that it's already protruding.

Soak the splines with penetrant and use a pickle fork to work the coupler off the splines.

-