You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stop in for a cup of coffee

- Thread starter toolmanmike

- Start date

-

Have a good guy working with me on it retired machinest and has a shop in his house. Few blocks away to boot! been asked alot for a setup like this lately since the hei is gaining ground.

I like the motorcyle jumping into the living room, reminds me of a record I have, Shooting Star I think lol!

Well get it built and be ahead of the curve, pun intended!Have a good guy working with me on it retired machinest and has a shop in his house. Few blocks away to boot! been asked alot for a setup like this lately since the hei is gaining ground.

Taking Suburban into 4WD shop today, don't want to deal with ball joint replacement, it's a pita, don't think you have to drill rivets out for this one but you do for some 10 bolt front ends I believe.

Good Morning Eric, hopefully things are a little bit better today for you all

Time to get mooving.

Coffee with the boys, then stick studebaker in shop. Test fit bench seat, so i can locate gas pedal. Its hard to drive with a string.

Coffee with the boys, then stick studebaker in shop. Test fit bench seat, so i can locate gas pedal. Its hard to drive with a string.

@Sublime one

Happy birthday John!

Happy birthday John!

Frodee

Off center a bit

Happy birthday John

Thank you Rich. Things are slowly smoothing out for her. It all just takes time.Good Morning Eric, hopefully things are a little bit better today for you all

Morning all ! Happy birthday John @Sublime one Cheers!

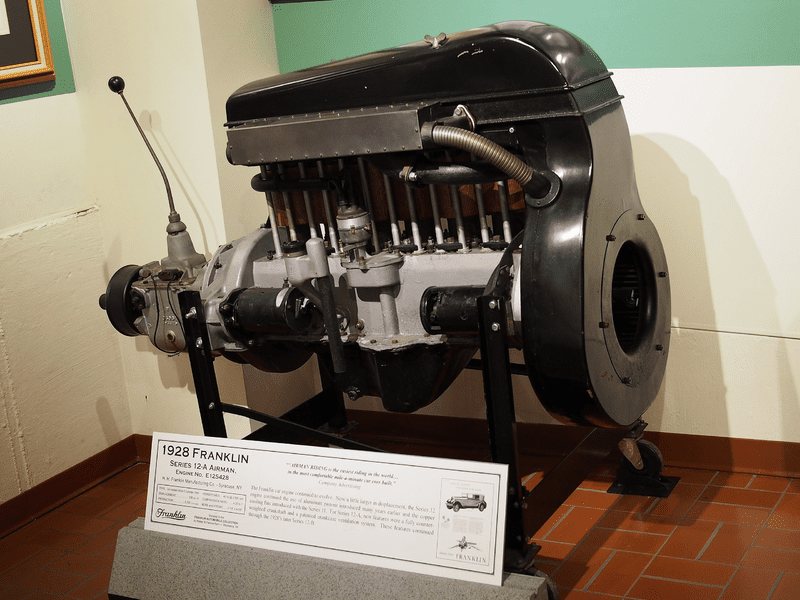

Its Franklin Friday! Matts car

Chassis

1928 12B was the last Franklin to have a wood chassis frame.Downdraft and Sidedraft Systems

The mid 20's saw the introduction of the pressure cooling, also known as the 'downdraft' system by which the fan, now moved to the front of the engine, forced air via ductwork over the TOP of the cylinders and downwards over vertical cooling fins cast into the sides of the cylinders. The cylinders were one-piece iron with non-detachable heads. The Ser. 10 had steel fins cast into the cylinders. The Ser. 11 - 13 had phosphor bronze fins. All had a pulse oil system which sent oil under full pressure to each main bearing and connecting rod in pulses. If a bearing was lost, pressure was maintained in the rest of the system, a dubious benefit since running very far with one bad rod could result in crankshaft damage or crankcase damage if the rod let go.All engines of this type were of 3 1/4" bore until the 135 engine which was increased to 3 1/5 x 4 3/4" stroke. The first series 10's were somewhat less than 30 horsepower, the final 135 engine was 65. All engines had overhead valves. The Series 13's were the first to use an AC fuel pump in place of the Stewart Warner vacuum tanks used from 1916 to 1928.

The great advantage of the downdraft system was the increased volume of air moved by the fan which was now pushing cooler, denser air instead of expanded, hot air which was pulled by the earlier flywheel/fan.

The disadvantage was the one-piece cylinder construction. It was very hard to cool the heads much and space for larger valves was limited. The result was occasional cracks in the cylinder heads and walls. In late '29, the factory cast a few iron cooling fins into the top of the cylinders. I have found that, oddly enough, these tend to crack more frequently than the earlier design.

The side-draft engines of 1930 - 1934 were certainly a great leap forward in performance and technology. One can always look to new technology and pass judgment on the old stuff as inferior in comparison. For its time, however, the downdraft engines were superb powerplants. They have a smoothness and quietness not found in the later side-draft design. The quality of construction was probably better than Franklin ever produced prior to, or after. The downdraft cars were and are capable of running full throttle all day long without detriment. The side-drafts, while beautifully engineered and certainly well built, produce so much more power that running full throttle all day long is not such a good idea as oil temps and piston speeds get out of hand.

Franklin Part Names

Transverse engine - Cross-engineRound hood - Barrel-hood

Cooling air flows down the cylinders - Down-draft

Hood style - Renault hood, Slop or soft-nose - Horse-collar

Name of body stylist – DeCausse

All Franklins from 1928 12A - Airman (except Olympic)

Air flows across the cylinders - Side-draft

Twelve cylinder - V12

Aluminum

Franklin bodies were all aluminum until 1929 in addition to other parts like crankcase, transmission, rear end housings, pistons, rods, and many other parts were also aluminum. It is not surprising that at one time Franklin Automobile Company was the largest user of aluminum the world.Happy Birthday John. Deja Vu. Didn't I do this yesterday?

Coffee is done.

- Joined

- Mar 17, 2018

- Messages

- 15,181

- Reaction score

- 35,771

Who cares! It is a multi day celebration! Thanks!

dukeboy440

Well-Known Member

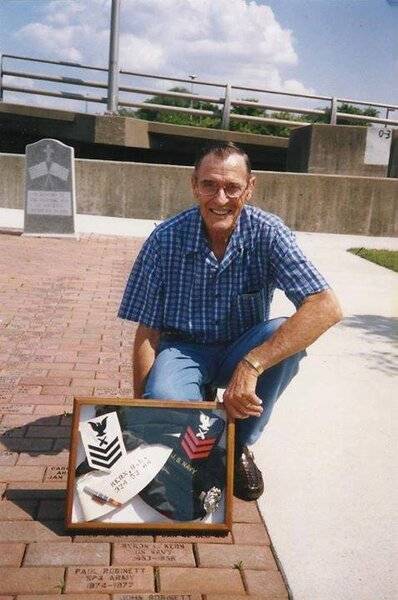

Well it was a LONG 16 hour day. With no sleep the night before cause my mind wouldn’t shut off. But survived and we did well.Spent all day yesterday prepping the Army Caisson team for the funeral today. Gonna be one for the record books for this team. We’re rolling out ALL the horses, normally we take just 4. Today, it’s all 8. We even had retired CSMs and even a star yesterday helping us prep everything. It’s a massive undertaking for any funeral but with this roll out, it was even more. Which is appropriate considering this NCO spent the last years of his life rebuilding this team into being respectable and active again.

It’s also the first time in the 50+ year history of both our Caisson and Arlington’s that the CAP horse, the riderless horse that carries just a saddle and a pair of boots, will actually be carrying the riding boots of our fallen NCO.

We also took the unprecedented step of meeting with the family at the showing last night. It’s gonna be a rough one today boys and girls.

I also get the added honor(pressure) of driving these horses to the funeral, something the man we are honoring today, always did. Hauling such prized and large draft horses is considered a very trusting and honorable position within our team so lots riding on this obviously.

Happy Veteran's Day and we thank you all for your service.

RIP to those no longer with us.

RIP to those no longer with us.

Last edited:

-