i agree. I think more than anything this is a chance to piggyback some features on a head that they are building for themselves as a first priority. If it can be made more versatile at little or no extra cost one would still have to sell them on that idea. It's a unique opportunity. When was the last time a company said "Hey we're thinking about building a cylinder head. Any ideas?". And on a open forum knowing full well how things can get sideways. I'll give them credit for that.He clearly stated parameters to work within, however, unless Blueprint comes up with something different than others offer, it might not be worth all the trouble, EXCEPT to simply supply THEMSELVES with heads for their own engines......and that'd be ok, too. I welcome anything new on the Mopar front, it would just be nice if someone offered something a bit different than what is already available.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suggestions for new design Aluminum Mopar SB clean slate (kind of) cylinder heads

- Thread starter Johnny Mac

- Start date

-

Which is one reason I started giving suggestions outside his parameters. Maybe they'll figure something out.i agree. I think more than anything this is a chance to piggyback some features on a head that they are building for themselves as a first priority. If it can be made more versatile at little or no extra cost one would still have to sell them on that idea. It's a unique opportunity. When was the last time a company said "Hey we're thinking about building a cylinder head. Any ideas?". And on a open forum knowing full well how things can get sideways. I'll give them credit for that.

When this post first stared I thought it was just an idea someone was kicking around that would never happen. A fun type of post that we sometimes come up with during the winter. But with the answers here and well within his boundaries it’s not only possible, it’s easy possible. And if you put his very first post and a couple others the blueprint is there.

Come up with with an aluminum magnum copy of a Speedmaster head cast in another country to keep cost down and slightly modify the pushrod hole moving it over a touch. I think the magnum style rocker simplifies this. He’s already planning on a 2.08 valve which is overkill for his 290 cfm target but would attract guys just wanting the heads. Now just come up with a “good” ported head to make a cnc program from which he stated would be done in America and add a street, street strip, or full race valve job and the needed spring package. The pan rail extension is a non issue on a fresh blueprint as would offering a couple different exhaust bolt patterns. The only drawback to this head in my eyes would be that for guys like me that has so much invested in the LA style head it wouldn’t be a viable option but a fantastic setup for his target group. Just to add something a simple tweak to his cnc program could take this 290 cfm head to a 325-330 or more if the material is there.

Come up with with an aluminum magnum copy of a Speedmaster head cast in another country to keep cost down and slightly modify the pushrod hole moving it over a touch. I think the magnum style rocker simplifies this. He’s already planning on a 2.08 valve which is overkill for his 290 cfm target but would attract guys just wanting the heads. Now just come up with a “good” ported head to make a cnc program from which he stated would be done in America and add a street, street strip, or full race valve job and the needed spring package. The pan rail extension is a non issue on a fresh blueprint as would offering a couple different exhaust bolt patterns. The only drawback to this head in my eyes would be that for guys like me that has so much invested in the LA style head it wouldn’t be a viable option but a fantastic setup for his target group. Just to add something a simple tweak to his cnc program could take this 290 cfm head to a 325-330 or more if the material is there.

When this post first stared I thought it was just an idea someone was kicking around that would never happen. A fun type of post that we sometimes come up with during the winter. But with the answers here and well within his boundaries it’s not only possible, it’s easy possible. And if you put his very first post and a couple others the blueprint is there.

Come up with with an aluminum magnum copy of a Speedmaster head cast in another country to keep cost down and slightly modify the pushrod hole moving it over a touch. I think the magnum style rocker simplifies this. He’s already planning on a 2.08 valve which is overkill for his 290 cfm target but would attract guys just wanting the heads. Now just come up with a “good” ported head to make a cnc program from which he stated would be done in America and add a street, street strip, or full race valve job and the needed spring package. The pan rail extension is a non issue on a fresh blueprint as would offering a couple different exhaust bolt patterns. The only drawback to this head in my eyes would be that for guys like me that has so much invested in the LA style head it wouldn’t be a viable option but a fantastic setup for his target group. Just to add something a simple tweak to his cnc program could take this 290 cfm head to a 325-330 or more if the material is there.

[/QU

Perfect!

Couldn't you take like Edelbrock Magnum head or whatever ported it out to a 290 cfm and make a mold from the port and then do a full on job even if it breaks through everywhere using epoxy etc.. to make it work for the 325-330 cfm port make a mold of that add a certain minimum thickness around that, use the 290 mold as cast and make a cnc program to port out to the second.

Couldn't you take like Edelbrock Magnum head or whatever ported it out to a 290 cfm and make a mold from the port and then do a full on job even if it breaks through everywhere using epoxy etc.. to make it work for the 325-330 cfm port make a mold of that add a certain minimum thickness around that, use the 290 mold as cast and make a cnc program to port out to the second.

Could he??? Yes. Should he??? No. Sometimes it’s better to start with a “clean” sheet of paper when you want to make several changes. Higher rail here, more material here, different bolt pattern here. Next thing you have is an abortion that looks like a moble home that you put three additions on.

Once you have the desired port shapes sure the rest would be drawn up in some computer program making whatever mods and compromises necessary.Could he??? Yes. Should he??? No. Sometimes it’s better to start with a “clean” sheet of paper when you want to make several changes. Higher rail here, more material here, different bolt pattern here. Next thing you have is an abortion that looks like a moble home that you put three additions on.

Once you have the desired port shapes sure the rest would be drawn up in some computer program making whatever mods and compromises necessary.

Keep One simple thing in mind. He’s not reinventing the wheel here. He simply and I said simply wants a 290 cfm head. Not the head WE want but one aimed towards his business of supplying 400-500 horsepower crate engines at a reasonable cost. Don’t make it complicated as it’s aimed to offer a product at a lower price point.

For me the basic plan for a 290 cfm magnum is good and fit the needs of 90% and would be interested in one at the right price point for my magnum engine, that's more than enough for me. To me anything else is bonus.Keep One simple thing in mind. He’s not reinventing the wheel here. He simply and I said simply wants a 290 cfm head. Not the head WE want but one aimed towards his business of supplying 400-500 horsepower crate engines at a reasonable cost. Don’t make it complicated as it’s aimed to offer a product at a lower price point.

For me the basic plan for a 290 cfm magnum is good and fit the needs of 90% and would be interested in one at the right price point for my magnum engine, that's more than enough for me. To me anything else is bonus.

That’s exactly why TrickFlow designed and produced a 300 cfm head instead of a more racier head. 90-95 percent are satisfied with it.

Don't say never. Trick Flow produced the 270 big block head that will feed 500 cubes and could make for a very potent smaller cube big block.That’s exactly why TrickFlow designed and produced a 300 cfm head instead of a more racier head. 90-95 percent are satisfied with it.

I would hope they are looking at the small block race market as there hasn't been a big block made since 1979.

Don't say never. Trick Flow produced the 270 big block head that will feed 500 cubes and could make for a very potent smaller cube big block.

I would hope they are looking at the small block race market as there hasn't been a big block made since 1979.

Ohhh they were before Covid as I talked to them several times. The main guy that I knew no longer works for TrickFlow so who knows what’s up now. Hell they can’t even get their small block Mopar intakes produced.

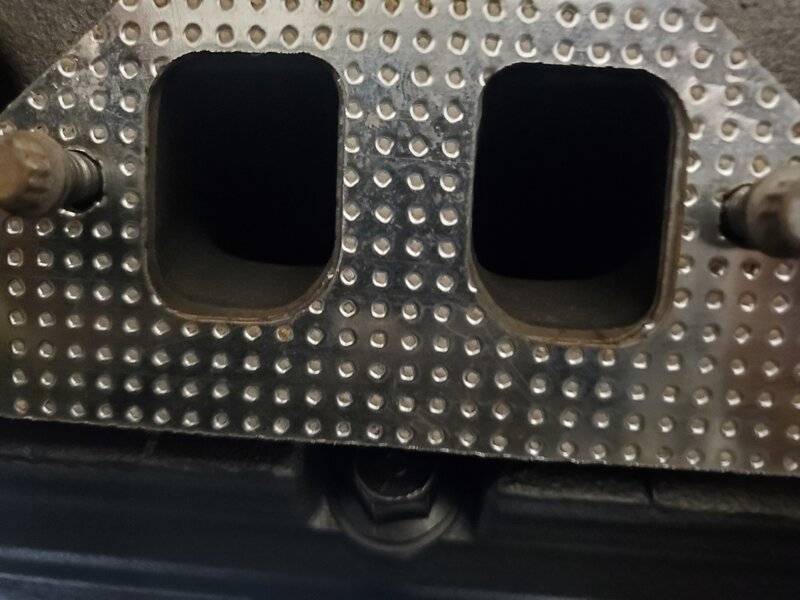

Thinking about magnum vs LA exhaust ports and header availability. Here are some pictures with a felpro 1413 gasket representing the LA port and a cometic gasket I had made representing the magnum port. gaskets are placed on...

(1) stock LA port

(2) EQ magnum port

(3) Speedmaster LA head

(4) stock magnum head

(1) stock LA port

(2) EQ magnum port

(3) Speedmaster LA head

(4) stock magnum head

(1) Stock LA

(2) EQ magnum

(3) speedmaster LA

(4) stock magnum

This is the gaskets next to each other.

The same header is used on all them, even though the ports are slightly different.Thinking about magnum vs LA exhaust ports and header availability. Here are some pictures with a felpro 1413 gasket representing the LA port and a cometic gasket I had made representing the magnum port. gaskets are placed on...

(1) stock LA port

(2) EQ magnum port

(3) Speedmaster LA head

(4) stock magnum head

Cuda416

Well-Known Member

Because of the hubbub about AFR heads....

AFR SBM heads (supposedly)

I thought I'd post here and ask whatever happened to this... Was it just an thought experiment or will anything come of the suggestions for a new clean slate head?

AFR SBM heads (supposedly)

I thought I'd post here and ask whatever happened to this... Was it just an thought experiment or will anything come of the suggestions for a new clean slate head?

Kendog 170

Let the boy go !

Say releasing Dec. 2024

The new small block head should look just like this, but in aluminum. lol

Cuda416

Well-Known Member

Say releasing Dec. 2024

Wait, what!?

That may be the sexiest 6 cyl head i have seenThe new small block head should look just like this, but in aluminum. lol

View attachment 1716327764

-