Okay cool, I'm going to run a 29.5 which for some reason is 30.6 tall, looks like she'll fitI wanna say it is a 29x15.5x15 but im not 100 percent on that..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Stock wheel arches.

- Thread starter Cope

- Start date

-

Cope

Fusing with fire

I will say this.

If I ever tub another car for my self (doubtfull) I would make the new tub go all the way up to the package tray.

Everyone wants wider tires but fitting a tall tire or being able to have the car sit low with a big tire is a very cool option.

If I ever tub another car for my self (doubtfull) I would make the new tub go all the way up to the package tray.

Everyone wants wider tires but fitting a tall tire or being able to have the car sit low with a big tire is a very cool option.

Yeah I agree with that 100%I will say this.

If I ever tub another car for my self (doubtfull) I would make the new tub go all the way up to the package tray.

Everyone wants wider tires but fitting a tall tire or being able to have the car sit low with a big tire is a very cool option.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,316

I've done a few tubs over the years, your right, sometimes it's just easier to clear the deck and start from scratch.I will say this.

If I ever tub another car for my self (doubtfull) I would make the new tub go all the way up to the package tray.

Everyone wants wider tires but fitting a tall tire or being able to have the car sit low with a big tire is a very cool option.

Ironracer

Gearhead

Badass, Dude!I can only speak for the ones on the white car in my first post.

My (old) car, The "ratty" white dart has mini tubs and the springs moved under the frame.

The super stock wheel arches (like mine) DO REQUIRE cutting AND welding.

We used small diameter rod to finish off the raw cut edge and give it a finished look. Just this is a fair amout of work due to it being "hot" work. You cant hammer form cold bar stock to floppy sheet metal so... yeah. That takes effort.

Next up required opening the back of the mini tub and pushing it back about 6 inches. Again a fair amount of work due to having to make the patchs on the english wheel.

We are running a 29x14.5x15 Hooser DOT slick on a custom with 9 inch ford. centered in the factory wheel opening.

So short answer is yes. Lots of fab work involved to do it like this. Its not just cutting but i cant speak for any other size or shape wheel arches.

I dont think their is a true correct way to do it. As far as I know all the SS cars were taken delivery of before the wheel arches were cut.

Cope

Fusing with fire

your right

I was wrong once.

I thought I made a mistake, Turns out. I was wrong.

I'd like to section the wheel arches up, forward & back to keep the factory opening and just fab in whatever I'll need.

I am also still contemplating extending the rear quarters and trunk area with the *** of a 68 I have.

I always wondered if a 70-71 front end would look cool on a 68 car, the front end is a little shorter on a 67-69 which I think helps out on the coolness of the 68

I am also still contemplating extending the rear quarters and trunk area with the *** of a 68 I have.

I always wondered if a 70-71 front end would look cool on a 68 car, the front end is a little shorter on a 67-69 which I think helps out on the coolness of the 68

—-Cool, I've looked & can't find. Where did you locate those?

Those were mine. I made those. I helped a young fellow out with his car. Next thing I see he’s selling copies on e bay the little turd.

—-Okay cool, I'm going to run a 29.5 which for some reason is 30.6 tall, looks like she'll fit

30.6”’ will be borderline tight at the front at the rocker area when you factor in tire growth.

Machineman63

Well-Known Member

Well. Its done. (Almost) I show up the other day and the Dart is now a "big tire" car and sporting SS wheel openings.

View attachment 1715827347

Did you build that rear wing?

Whatta jerkoffski—-

Those were mine. I made those. I helped a young fellow out with his car. Next thing I see he’s selling copies on e bay the little turd.

Ooh, then I might reconsider welding a plate in front of my inboard spring boxes—-

30.6”’ will be borderline tight at the front at the rocker area when you factor in tire growth.

—-Ooh, then I might reconsider welding a plate in front of my inboard spring boxes

Yeah the 29.5 X 11.5W can be anywhere from 30” to 31”. My last set were 30.6”. They fit at the front but there’s approx 3/4” space. A second bolt hole on either the spring box or spring perch will give the room needed.

Cool thanks for the advice.—-

Yeah the 29.5 X 11.5W can be anywhere from 30” to 31”. My last set were 30.6”. They fit at the front but there’s approx 3/4” space. A second bolt hole on either the spring box or spring perch will give the room needed.

ns1rm21

Well-Known Member

- Joined

- Feb 22, 2008

- Messages

- 660

- Reaction score

- 640

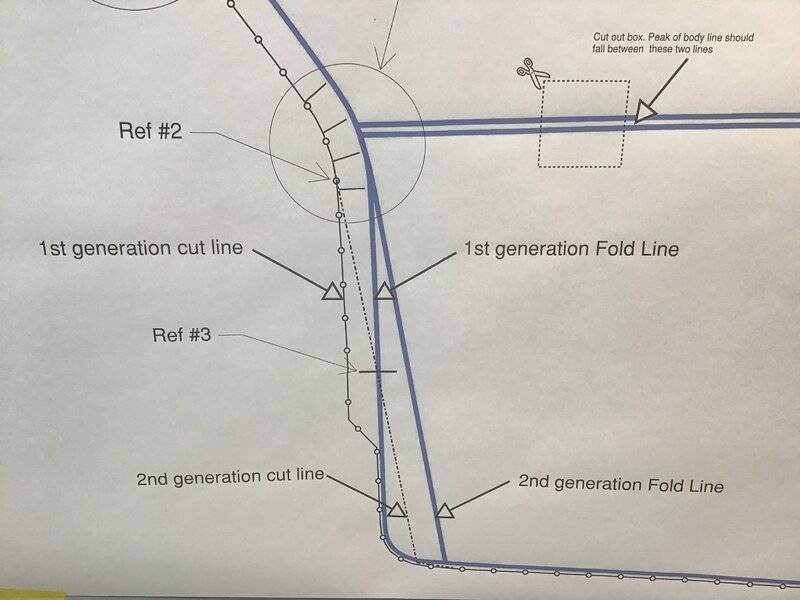

1968 Super Stock Hemi Dart wheel well cut out Templates.

At last, we finally got these done. I have been asked to do these for several years and now they are complete. I have been following these cars for over thirty years and the question has always come up, “What shape did they use on the rear wheel cutouts?” The truth is back in the day there was a template, but the workers took “liberty’s” when cutting them out. There were at least two common versions used and this template has both of them are on this template

1. What you get is a complete template that has both the first and second generation of wheel well cut outs.

2. Complete 8 page set of instructions with illustrations that tells and shows you step by step on how to perform this procedure using simple tools.

3. List of “Helpful hints” that will help you complete this task.

You get all this for $85.00 plus $24.50 shipping anywhere in the lower 48 states. For other locations please contact me and I’ll figure out the shipping cost.

My email / PayPal account it [email protected]

I prefer PayPal or money order. Thanks for looking.

Troy Bray

Last edited:

67DodgeDart360

Well-Known Member

Check out the templates on eBay. 1968 Hemi Dart Super Stock Wheel well templates “Paper” | eBay

—-Cool, I've looked & can't find. Where did you locate those?

I made those. The guy selling them asked if I would make him a set. To help a young fellow out I did. Next thing I know, a Mopar acquaintance alerts me that he’s selling copies on eBay. Glad that I kept the originals.

I like yours, does the front go all the way as far as possible ? I have a 30.60 tall tire with the Dana sitting in the stock perch hole—-

I made those. The guy selling them asked if I would make him a set. To help a young fellow out I did. Next thing I know, a Mopar acquaintance alerts me that he’s selling copies on eBay. Glad that I kept the originals.

View attachment 1715986151

View attachment 1715986152

View attachment 1715986154

ns1rm21

Well-Known Member

- Joined

- Feb 22, 2008

- Messages

- 660

- Reaction score

- 640

—-I like yours, does the front go all the way as far as possible ? I have a 30.60 tall tire with the Dana sitting in the stock perch hole

Yes mine do. They go flush to the tub. 30.6” tire fits, that’s the same size that I have for my Dart. There’s about an inch left for growth. Each side tub should be checked for being installed square on the car, may need a little massaging. NR1 member has a nice set advertised

MidnightSwinger

Well-Known Member

It looks amazing. What do you do after cutting to finish the edge? Do you roll it at all or weld it?—-

Yes mine do. They go flush to the tub. 30.6” tire fits, that’s the same size that I have for my Dart. There’s about an inch left for growth. Each side tub should be checked for being installed square on the car, may need a little massaging. NR1 member has a nice set advertised View attachment 1715986170

—-It looks amazing. What do you do after cutting to finish the edge? Do you roll it at all or weld it?

Welded.

Lip is 1/2” throughout, tub is fit finished and welded.

ns1rm21

Well-Known Member

- Joined

- Feb 22, 2008

- Messages

- 660

- Reaction score

- 640

The templates I sell have both the “early as delivered” cut outs that works with a 28” tall tire and the “second generation” cut out that goes all the way to the front of the tub and will take a 30” tall tire. The templates I have can also be altered to work with what ever requirements you need.

-