PRH

Well-Known Member

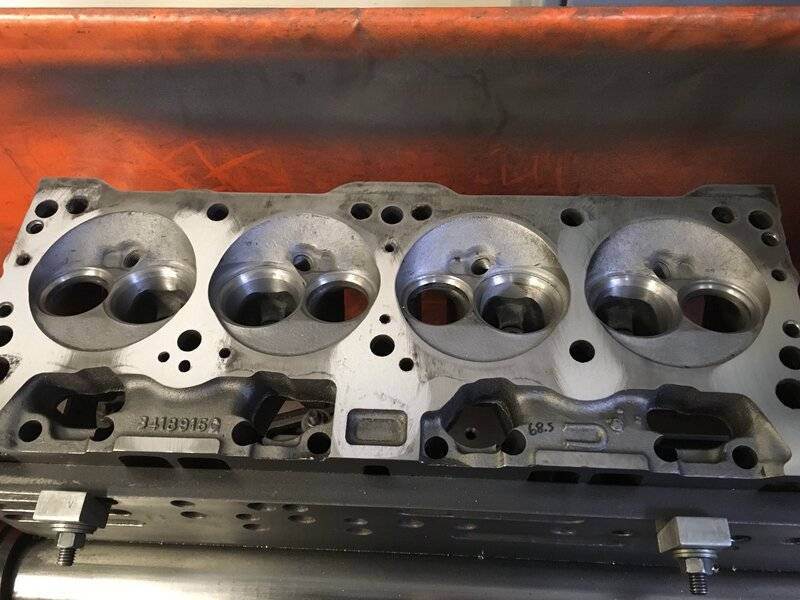

This is what the head looked like after milling.002”

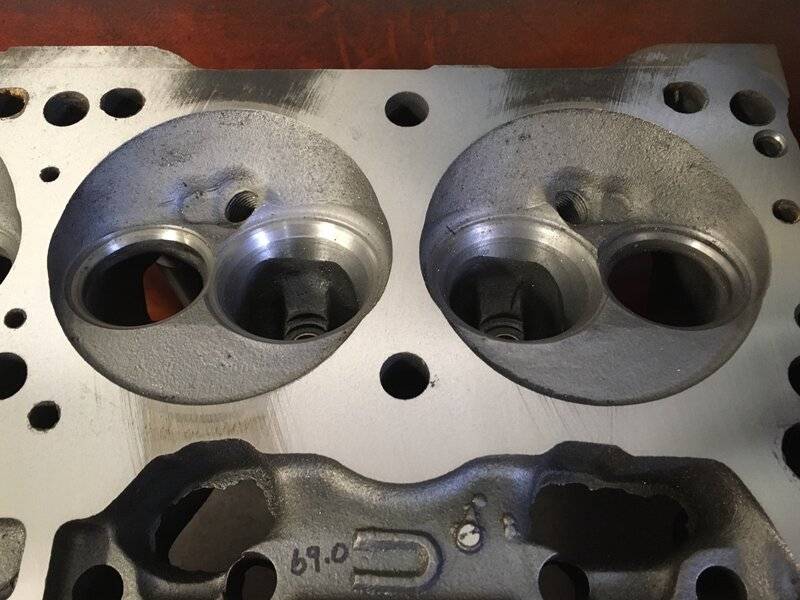

Second pic was after .005”

Second pic was after .005”

Second picture. Was this usable or did you cut it more?This is what the head looked like after milling.002”

Second pic was after .005”

View attachment 1716013804

View attachment 1716013805

Second picture. Was this usable or did you cut it more?

They were cut until flat.Second picture. Was this usable or did you cut it more?

Its absolutely amazing the crap work that comes from so many shops.The heads had been assembled with aftermarket springs and retainers.

Springs were set up at 60lbs on the seat......and 190lbs@ .500” lift(less than stock on both ends).

New springs are 115lbs on the seat, 285@ .500” lift.

Retainers were aluminum....... so those didn’t get reused.

The bottom end is getting a basically stock rebuild...... with a little bump up in the cam dept.

It's nice to see one that doesn't.Its absolutely amazing the crap work that comes from so many shops.

Is that what they refer to as "warp speed"? LOLThis is what the head looked like after milling.002”

Second pic was after .005”

View attachment 1716013804

View attachment 1716013805