Okay, feel free to let me have it if you think that this is a bad idea but.....

To those that want their cars to handle better, aligning the car to have more caster really helps.

There are numerous ways to get there, some are more effective than others. You can crack open the wallet and buy aftermarket stuff. The Hotchkis stuff seems to be almost infinitely adjustable but holeeeee crap they are expensive.

Even the Firm Feel is spendy...

With the Firm feel, you're at the mercy of whatever added caster they engineer in. That is fine but still...$450?

FABO sponsor PST doesn't list one for the A body.

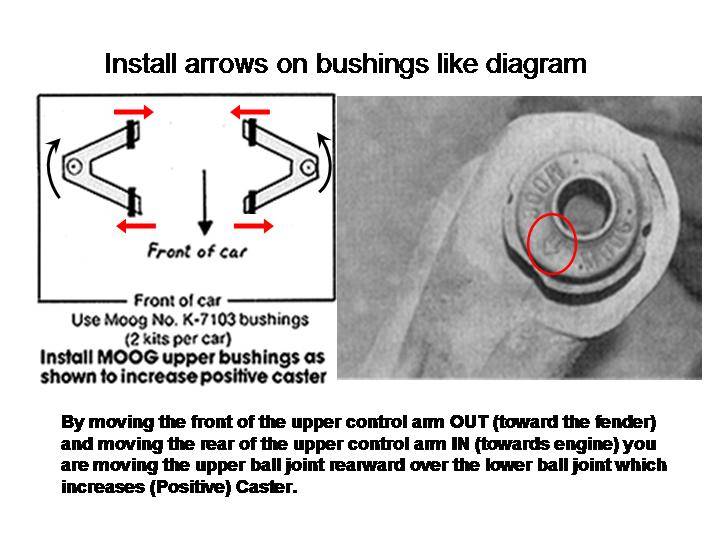

If you like your stock stamped steel arms, you're limited to using the Moog K-7103 offset bushings:

They do work, I have them in my '70 Charger. I must be blessed though because even with standard bushings, this car was able to get over 3 degrees of caster. Now with the bushings, I was able to get 5 degrees on one side, 5.5 on the other. This has to be a case of an absolute positive tolerance stack up!

Okay, back to the point. If you're always looking to do more with less and can weld....

How about this?

How about cutting the UCA on the forward leg, spread it 1/4" and welding in another section?

Properly welded, it wouldn't fail. The slight change in angle will affect the rear bushing slightly but not enough to matter. This can be done for next to nothing. The 1/4" piece sectioned in could come from small ball joint UCAs that are not as valuable to some people. By welding in an extension, you'd still be able to use any type of bushing, offset or stock so there would still be the same range of adjustment.

Opinions?

To those that want their cars to handle better, aligning the car to have more caster really helps.

There are numerous ways to get there, some are more effective than others. You can crack open the wallet and buy aftermarket stuff. The Hotchkis stuff seems to be almost infinitely adjustable but holeeeee crap they are expensive.

Even the Firm Feel is spendy...

With the Firm feel, you're at the mercy of whatever added caster they engineer in. That is fine but still...$450?

FABO sponsor PST doesn't list one for the A body.

If you like your stock stamped steel arms, you're limited to using the Moog K-7103 offset bushings:

They do work, I have them in my '70 Charger. I must be blessed though because even with standard bushings, this car was able to get over 3 degrees of caster. Now with the bushings, I was able to get 5 degrees on one side, 5.5 on the other. This has to be a case of an absolute positive tolerance stack up!

Okay, back to the point. If you're always looking to do more with less and can weld....

How about this?

How about cutting the UCA on the forward leg, spread it 1/4" and welding in another section?

Properly welded, it wouldn't fail. The slight change in angle will affect the rear bushing slightly but not enough to matter. This can be done for next to nothing. The 1/4" piece sectioned in could come from small ball joint UCAs that are not as valuable to some people. By welding in an extension, you'd still be able to use any type of bushing, offset or stock so there would still be the same range of adjustment.

Opinions?

Last edited: