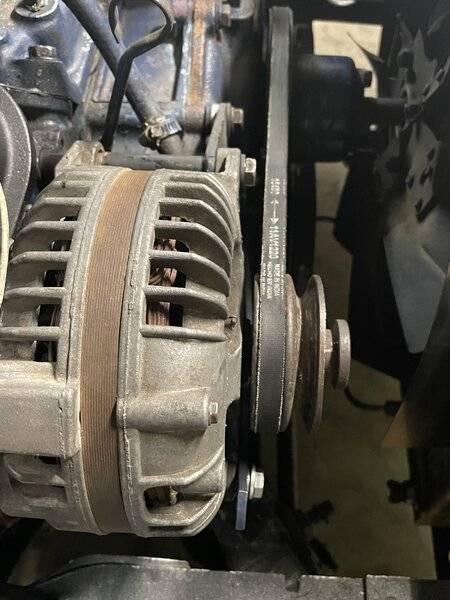

Here is something else to think about..............what is the diameter of your crank pulley, what is the diameter of your alternator pulley? Years ago I was having the same problem of throwing belts, it came down to 2 things:

1. the drive ratio of crank pulley to alternator was 1 to 2, so at 6000rpm crank speed, the alternator was spinning 12,000 rpm AND;

2. the alternator was built with bushings instead of bearings causing significant drag (cheep Autozone alternator ), replaced alternator with one using ball bearing construction, problem solved. I would have swaped out pulley on alternator to a larger one if needed to slow alternator down but was not needed.

In solving this problem, working in the driveway, I could watch the belt stretch like a rubber band as rpm climbed; didn't make any difference how belt was adjusted to begin with.

Again something to think about.

Good luck!