brasil

Well-Known Member

Hello ...

I am trying to set my timing.... but it seems to be a long way to get good results..

My set up..... 1973 340 cui block with x heads 1971 Cast iron Intake HP Manifolds 800 cfm

TQ with 97 pri and 139 sec 1966 rods... accel Distributor ( the OEM Mopar look-a like )

Unfortunatly the cam is unknown.... also the cr ratio..

Compression is very good 180 psi ( cold engine) +/- 5 psi....

Only the vacuum is low... 11-12 " HG @ idle... ( 900 rpm )

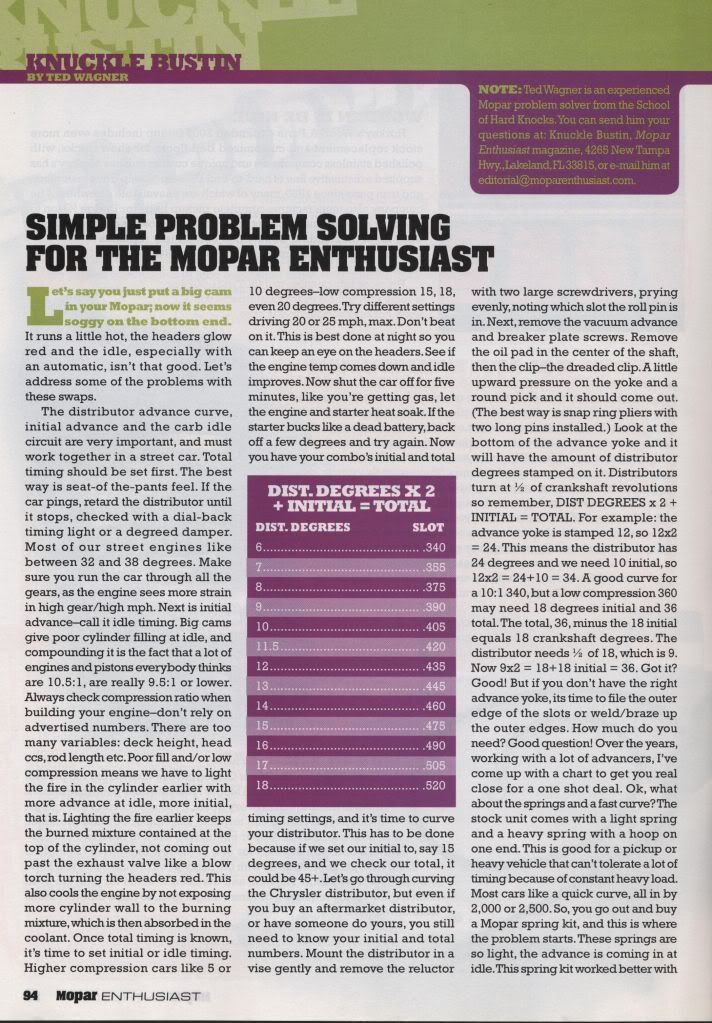

so when I set the timing around 16-20 deg BTDC the engine runs o.k. I limited the advance so all in is 35 deg. ( vacuum on top )

My Problem ist..a light pinging while accelerating...while cruising.... I think it is the CURVE

seems to be too fast ..too soon.. too what ever...

What is a good curve.... to use.. a very fast one.. all in @ 2000 rpm or is there an advantage of using a slow curve.. all in @ 3000 + rpm....

Normaly a High CR engine needs less timing @ idle.... but a big cam loves more timing...as far as I read... so do I have a change to come to an end.. with this issue...? without pulling the heads - to check the CR ??

Thank you for your help

Greetings Juergen

I am trying to set my timing.... but it seems to be a long way to get good results..

My set up..... 1973 340 cui block with x heads 1971 Cast iron Intake HP Manifolds 800 cfm

TQ with 97 pri and 139 sec 1966 rods... accel Distributor ( the OEM Mopar look-a like )

Unfortunatly the cam is unknown.... also the cr ratio..

Compression is very good 180 psi ( cold engine) +/- 5 psi....

Only the vacuum is low... 11-12 " HG @ idle... ( 900 rpm )

so when I set the timing around 16-20 deg BTDC the engine runs o.k. I limited the advance so all in is 35 deg. ( vacuum on top )

My Problem ist..a light pinging while accelerating...while cruising.... I think it is the CURVE

seems to be too fast ..too soon.. too what ever...

What is a good curve.... to use.. a very fast one.. all in @ 2000 rpm or is there an advantage of using a slow curve.. all in @ 3000 + rpm....

Normaly a High CR engine needs less timing @ idle.... but a big cam loves more timing...as far as I read... so do I have a change to come to an end.. with this issue...? without pulling the heads - to check the CR ??

Thank you for your help

Greetings Juergen