racerjoe

Well-Known Member

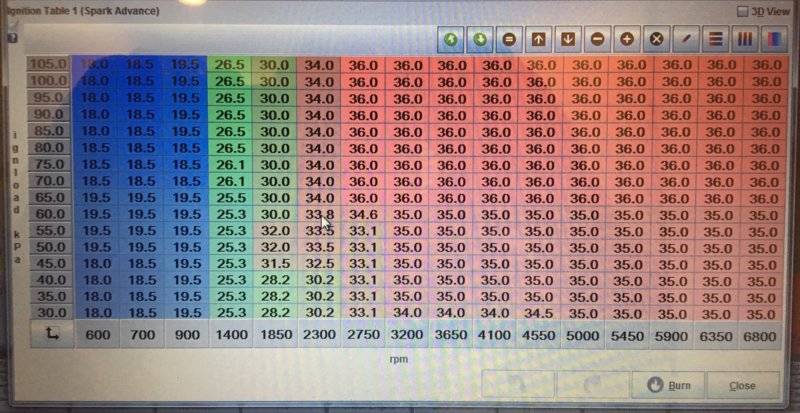

I'm running sequential EFI and spark on a 408ci w/ aluminum heads and approximately 9.5:1 compression. I can set the timing advance to anything I want at any RPM, and any load level. I know it would be best to tune on a dyno, but I don't have access to one at the moment. Below is my current timing table. My cam RPM range is 2500-6800. Initially I didn't have all the timing in (36 degrees) until about 3200RPM and it was a little sluggish during acceleration. I changed it to what you see below and it made a huge difference. I was wondering if anyone has input on when full advance should come in. Should it be all in (36) at 2500, or can I bring it all in sooner than 2500RPM? Does anyone run more than 36 degrees? FYI, this is a street car.

The engine idles at about 850RPM and 55-60kpa. You can ignore those cells as they are only used during decel, or warmup. It follows a different timing table at idle.

The engine idles at about 850RPM and 55-60kpa. You can ignore those cells as they are only used during decel, or warmup. It follows a different timing table at idle.