I am installing a new cam and timing chain in my 318. I have the#1 piston at TDC on the compression stroke. When I took the timing cover off I noticed that the marks on the timing chain are in line, but both are at the 12 0clock position. The chilton book and the install instructions for the timing chain both say the alignment marks should at the 12 0 clock position on the crank sproket and at the 6 0 clock position on the cam sproket. WTF! :sad2:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

timing chain install question

- Thread starter devildart

- Start date

-

340GTSDart

Well-Known Member

Rotate it one more full crank revolution and it will be at TDC on the compression stroke. Then the cam mark will be at 6 oclock and the crank will be at 12 oclock. Make sure your distributor's rotor is lined up with #1 on the distributor cap and your good to go. Fire it up and set the timing.

Thats what I thought, but no go. the intake is off and the distributor is out,but that doesnt matter. I am rotating the crank and I can watch the valves go through their cycles. Intake compression power and exhaust. I just cycled it four times, and every time I get to TDC on the compression stroke, the sproket alignment dots are both at the 12 0 clock position. Another quick simple project turning into a nightmare. :sad2:

Mrmopartech

Well-Known Member

When doing the timing chain alignment and getting the marks at 12 o,clock and 6 o,clock,the cylinder that will be at TDC is,NO.6.The timing chain marks are used with no.6 cylinder.When setting ignition timing and putting your distributor you are using NO.1.Mrmopartech

So if I read this right, it should be explained as, the dot to dot will have #6 fireing and not #1.

Reguardless, set up the cam on the dot to dot (Crank 12, cam 6 O'clock(s) and set the distributor rotor to point to the number 1 cyl.

Sound right Mr. M

Reguardless, set up the cam on the dot to dot (Crank 12, cam 6 O'clock(s) and set the distributor rotor to point to the number 1 cyl.

Sound right Mr. M

Mrmopartech

Well-Known Member

Rummy,you are 90% right,its after you are done setting the marks,turn the crank one full turn and you will be on compression on NO.1,Mrmopartech

Thanks everyone for your help. When #6 is at TDC on the compression stroke, the chain does line up dot to dot. The last cam change I did on an engine like this was 3 years ago on a 360 in my 90 ramcharger. If I remember correctly, I got the #1 piston to TDC and changed everything with the dots both at 12 0 clock and everything worked ok. Also if anyone is interested, i'm doing this work on a 1968 318 with 30,000 original miles on it. would like to sell the old parts i'm swapping out as a package: cam, lifters, springs, balancer, valve covers, two barrel intake with carb and air cleaner. The engine was painted with mopar engine paint before it was installed in my dart, so the parts look nice. Will list the parts later in a seperate post with pics when I have time. Not trying to get rich, just dont want the stuff sitting around and my dart needs gas. :evil2:

65s

Well-Known Member

I just replaced the timing chain on my 273, mileage unknown but the chain had about 1" of play in it. I've never done this before, and I had a friend who has, helping. Once we got the timing cover off, we noticed the dots didn't line up at all, but after we rotated things they lined up. I put the new sprockets on but found the dots didn't line up quite right, they were off by about 1/2 a tooth. If I moved them one tooth, then they were WAY off, so I put them as best as possible and chalked it down as "as good as it gets". My woodruff keys appeared to be stock. I believe offset keys are used when you get into setting your timing with a dial indicator and all that...too fancy for me!

Anyhow, my engine runs like crap, but it did before too...so I think there's some other problems. Overall I enjoyed the experience and I'll likely do it again sometime, I'm much more confident now.

Anyhow, my engine runs like crap, but it did before too...so I think there's some other problems. Overall I enjoyed the experience and I'll likely do it again sometime, I'm much more confident now.

z_daddy

z_daddy

Hey can you explain this to me I'm not getting itThanks everyone for your help. When #6 is at TDC on the compression stroke, the chain does line up dot to dot. The last cam change I did on an engine like this was 3 years ago on a 360 in my 90 ramcharger. If I remember correctly, I got the #1 piston to TDC and changed everything with the dots both at 12 0 clock and everything worked ok. Also if anyone is interested, i'm doing this work on a 1968 318 with 30,000 original miles on it. would like to sell the old parts i'm swapping out as a package: cam, lifters, springs, balancer, valve covers, two barrel intake with carb and air cleaner. The engine was painted with mopar engine paint before it was installed in my dart, so the parts look nice. Will list the parts later in a seperate post with pics when I have time. Not trying to get rich, just dont want the stuff sitting around and my dart needs gas. :evil2:

If both dots are 12 oclock you are at #1 tdc. You CAN put crank at 12 and cam at 6 BUT you are now on #6 tdc.

Hey can you explain this to me I'm not getting it

Ford and GM lined the dots up together #1 compression stoke. The Dodge Brothers ( who provided the a model engines to Ford btw ) have always did this a little different. I've heard that their reason had something to do with cam and lifter positions for pre oiling. Another said it had to do with fixtures and/or pre tests on assembly line. I always thought it was simple logic. The closer together the 2 dots are, the easier to sight a straight line from .2. Who knows ? In the end it doesn't matter.

Since the crank is going to turn two revolutions for every cam revolution, 1 crank rev' = 1/2 cam rev'.

So... set the dots in either position, put the chain on, and turn the engine. One dot set up will lead to the other.

Only variables remaining are slot in distributer drive and rotor position.

Most cases, following the written instructions will lead to success.

Since the crank is going to turn two revolutions for every cam revolution, 1 crank rev' = 1/2 cam rev'.

So... set the dots in either position, put the chain on, and turn the engine. One dot set up will lead to the other.

Only variables remaining are slot in distributer drive and rotor position.

Most cases, following the written instructions will lead to success.

Last edited:

OK, so I'm a little slow and I just came across this

posting after doing an internet search

I have a 74 Dart 318, the cam gear broke and

I replaced it...Using number cylinder

but reading here, it is No. 6 that is at TDC

when the gear set is installed..

Should I then set No. 6 to TDC and install

the gear set with the marks at 6 and 12

My Haynes book has no mention of this.

any suggestions would be appreciated..

Best

posting after doing an internet search

I have a 74 Dart 318, the cam gear broke and

I replaced it...Using number cylinder

but reading here, it is No. 6 that is at TDC

when the gear set is installed..

Should I then set No. 6 to TDC and install

the gear set with the marks at 6 and 12

My Haynes book has no mention of this.

any suggestions would be appreciated..

Best

nm9stheham

Well-Known Member

Both #1 and #6 will be at TDC at the same time; so, put either one at TDC, and align the cam & crank sprockets either exactly at 12&12 or at 6&12. (Use a straight edge to make sure the line through both dots passes exactly through the center of the cam bolt.)

If the dots arae aligned at 6 and 12, then #6 is firing so put the distributor rotor one #6 spark tower. If the dots are aligned at 12 and 12, #1 is firing so put the rotor on #1 spark tower.

If the dots arae aligned at 6 and 12, then #6 is firing so put the distributor rotor one #6 spark tower. If the dots are aligned at 12 and 12, #1 is firing so put the rotor on #1 spark tower.

That clears it up a little..Thanks

Just could not figure out why after I set the gears

the first time, I had to move the Dust 15 deg to

get it on 0 TDC No.1 firing...

Need to get this beast back on the road and sold

Just could not figure out why after I set the gears

the first time, I had to move the Dust 15 deg to

get it on 0 TDC No.1 firing...

Need to get this beast back on the road and sold

put the crank at 12 oclock...the cam at 6 o clock to get the dots to line up....simple....install the timing chain...

now...at those postions...you are on number 6 firing....no biggie...rotor should be pointing at number six on the cap.....simple

rotate engine one turn....cam dot now at 12 o clock....crank at 12 o clock....you are not on no. 1 firing....rotor should be pointing at no. 1 on the cap...simple....

now...at those postions...you are on number 6 firing....no biggie...rotor should be pointing at number six on the cap.....simple

rotate engine one turn....cam dot now at 12 o clock....crank at 12 o clock....you are not on no. 1 firing....rotor should be pointing at no. 1 on the cap...simple....

67Dart273

Well-Known Member

..... and GM lined the dots up together #1 compression stoke.

.

Uh, no, LOL. At least some SBC lined up dot to dot were on no 6 ready to fire, just like Mopars

"I suspect" that these are not all marked the same.

nm9stheham

Well-Known Member

So do you mean you moved the distributor itself physically 15* to get the rotor to line up close to the #1 spark tower on the cap? Some small mis-alignment of the spark tower is common. And who knows what the prior timing setting was. (Also, the timing advance mechanism in the distributor can throw off the rotor pointing if it is fouled up.)That clears it up a little..Thanks

Just could not figure out why after I set the gears

the first time, I had to move the Dust 15 deg to

get it on 0 TDC No.1 firing...

Need to get this beast back on the road and sold

Once you get the sprockets aligned, and the front timing cover and damper on, then you actually should set the timing by:

- moving the crank a bit CCW to the initial advance value you want (by adjusting the crank damper mark to the desired timing marks on the timing cover)

- then adjusting the distributor to have it firing at that actual timing setting by setting it for one of the distributor's 8 trigger teeth being right at the gap in the ignition pickup (for the stock Mopar electronic ignition) where the appropriate spark tower is also aligned with the rotor

Easier to show than describe in words!

pishta

I know I'm right....

I just did a 273 with a slightly used silent chain and a tensioner. The dots lined up exactly with the chain in place. Remember that the crank doesnt know its on the compression or exhaust stroke, its the cam that determines that. When you line up the dots, make sure there is tension on the driver side. If the dots are 12 and 12, turn it once and it will be 6 and 12, twice and it will be 12 and 12 again. Dont even worry about pistons at TDC, the dots will be your guide. once you get the cam timing, then you find #1 TDC looking at the intake cam lobe: lobe should be about 90 past where it would act on the intake lifter. Your piston should be very close to TDC and your damper mark should be hovering within a few degrees of the TDC tick mark. now drop the distributor in with the rotor pointing towards the #1 piston corner intake bolt. Wire the cap in that manner.I just replaced the timing chain on my 273, mileage unknown but the chain had about 1" of play in it. I've never done this before, and I had a friend who has, helping. Once we got the timing cover off, we noticed the dots didn't line up at all, but after we rotated things they lined up. I put the new sprockets on but found the dots didn't line up quite right, they were off by about 1/2 a tooth. If I moved them one tooth, then they were WAY off, so I put them as best as possible and chalked it down as "as good as it gets". My woodruff keys appeared to be stock. I believe offset keys are used when you get into setting your timing with a dial indicator and all that...too fancy for me!

Anyhow, my engine runs like crap, but it did before too...so I think there's some other problems. Overall I enjoyed the experience and I'll likely do it again sometime, I'm much more confident now.

Last edited:

TrailBeast

AKA Mopars4us on Youtube

And in the end it doesn't really matter because if you get it wrong/different you just pop the distributor out, turn the rotor 180 degrees and drop it back in.

Thats true...

Like I said I set the gear timing marks like I would

on my Fords.. but when I started the engine it was

not near TDC #1.. I had to advance it a lot,

A friend of mine who is a Mopar guy was assisting

me, and he could not understand how it was off so

far.. Anyway, I'll be much more careful this time

to make sure I get the "dots" correctly aligned right

thanks again

Like I said I set the gear timing marks like I would

on my Fords.. but when I started the engine it was

not near TDC #1.. I had to advance it a lot,

A friend of mine who is a Mopar guy was assisting

me, and he could not understand how it was off so

far.. Anyway, I'll be much more careful this time

to make sure I get the "dots" correctly aligned right

thanks again

pishta

I know I'm right....

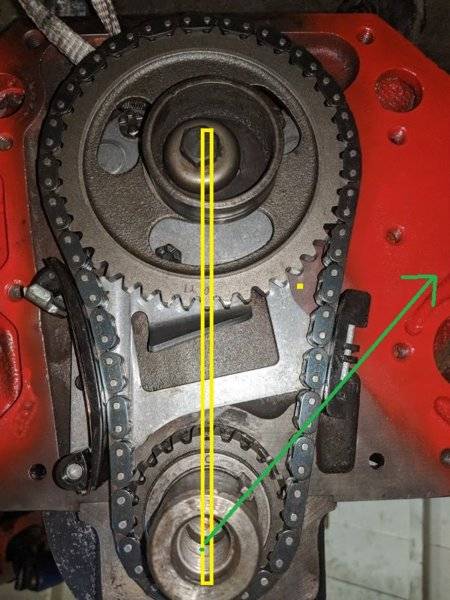

here is mine. The motor is upside down so I cant see the cam timing but I do know that dot to dot does equal TDC on #1 (and #6) on a stock chain. Green line is #1 rod position

46 teeth up top, 23 down below, 2:1.

46 teeth up top, 23 down below, 2:1.

Last edited:

nm9stheham

Well-Known Member

Your distributor may just not have been timed well to start. (But I am assuming that the distributor was pulled... which may not be true.) The ignition timing is varied by the distributor alone... it can be anywhere.Thats true...

Like I said I set the gear timing marks like I would

on my Fords.. but when I started the engine it was

not near TDC #1.. I had to advance it a lot,

A friend of mine who is a Mopar guy was assisting

me, and he could not understand how it was off so

far.. Anyway, I'll be much more careful this time

to make sure I get the "dots" correctly aligned right

thanks again

Also, it has been known for the outer ring of the damper, that carries the timing mark, to slip when the get old, and that will throw off the ignition timing. The only way to know if this damper mark is right is to use a piston stop to locate the true TDC position of #1; when there, then the timing mark on the damper should align with the 0 mark on the timing cover's marks.

OK, so I'm a little slow and I just came across this

posting after doing an internet search

I have a 74 Dart 318, the cam gear broke and

I replaced it...Using number cylinder

but reading here, it is No. 6 that is at TDC

when the gear set is installed..

Should I then set No. 6 to TDC and install

the gear set with the marks at 6 and 12

My Haynes book has no mention of this.

any suggestions would be appreciated..

Best

This thread will show how the timing chain is installed:

How to Assemble the Front of a Small Block

-