You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torsion Bars

- Thread starter CRUZE 418

- Start date

-

FSM says "dress up" any scores or scratches

I always wondered about this......I assume that the T bars would be prone to road damage etc. Would that necessitate replacement?

We used to beat them out with vice grips all the time when I was a kid. Never had a problem........LOL, not saying that it's right, but that's what we did!

We used to beat them out with vice grips all the time when I was a kid. Never had a problem........LOL, not saying that it's right, but that's what we did!

autoxcuda

Well-Known Member

- Joined

- Apr 6, 2007

- Messages

- 9,057

- Reaction score

- 4,148

I bought some new MP 1.14" torsion bars that must have got a 1/2" long nick/gouge in shipping or customer handling them. They were that primer green that MP torsion bar came in.

Hard to describe how deep the gouge was. I was big enough to catch your fingernail and hold it.

I dressed the nick with a rubber impregnated grinding wheel and removed all of the gouge. So technically it's out of round in one spot. Now these are 1.14" so there's a lot of meat to them. I don't think it had any significant effect on spring rate.

Been running them for 10 years now. At track, off track excursions, on street, wherever.

Cant find picture of gouge before and after. But this was is my T-bar and measurement

Hard to describe how deep the gouge was. I was big enough to catch your fingernail and hold it.

I dressed the nick with a rubber impregnated grinding wheel and removed all of the gouge. So technically it's out of round in one spot. Now these are 1.14" so there's a lot of meat to them. I don't think it had any significant effect on spring rate.

Been running them for 10 years now. At track, off track excursions, on street, wherever.

Cant find picture of gouge before and after. But this was is my T-bar and measurement

Last edited:

Post a pic of what you have. A small scratch or nick can be cleaned up. A roloc disc to knock down the sharp stress risers will do the trick.

Get the torsion bar removal tool, its cheap insurance. More so now than ever since the price of torsion bars have seem to tripled or more.

Get the torsion bar removal tool, its cheap insurance. More so now than ever since the price of torsion bars have seem to tripled or more.

I read this scratch the torsion bar in the fabo newsletter this am. I had assumed that I had hurt the torsion bars when removing them with a pair of vise grips. I just looked at the T-bars and they seem to look fine except for scratching the paint up. I got lucky this time, but now I know! I had a thin piece of rubber in jaws of the vise grips, maybe that helped save the day.

Thank you guys again for helping someone who Flys off the handle every now and then! Thinking that I have a problem, and then don't. My apologies.

Merry Christmas and Happy New Year.

Thank you guys again for helping someone who Flys off the handle every now and then! Thinking that I have a problem, and then don't. My apologies.

Merry Christmas and Happy New Year.

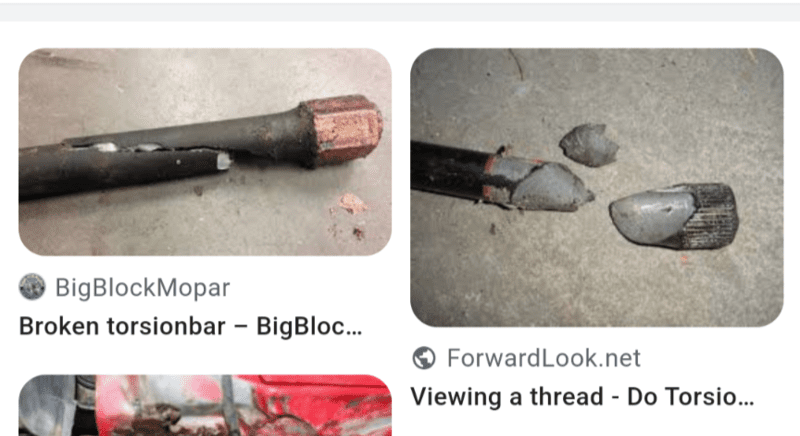

I , myself would like to see one that broke because of a scratch or even a ding,dent whatever. These bars are tough and subject to this abuse from driving, jack stands ect. I have yet to find a broken T bar .

Al, It happens but is rare and no one really knows why, scientifically.

Lol. “No one knows scientifically”.

There is absolutely a scientific explanation for why that bar fractured.

Maybe no one bothered to have that reason determined, but a materials science analysis could tell you exactly why.

I have never experienced a broken bar but have seen a few posts on the forums over the years so it does happens. I have seen at least two occasions where the car was just sitting and the next day it was sitting lower on one side.

Eventually metal fatigues and will give out. I would bet we will be seeing more of this in the future due to the excellent quality of metal these days.

Eventually metal fatigues and will give out. I would bet we will be seeing more of this in the future due to the excellent quality of metal these days.

It's rare, but certainly not unheard of, there are multiple causes so there's no way to guess which one without a "forensic" analysis.

I exprienced the 1st one in the tech-school garage, instructor was leaning against the fender, BANG!!! & it was on the lower arm.

The 2nd was just months later, carpooling in Gary's /6 3spd Duster, halfway up I-79..BANG!!!....& We were riding on the RF lower arm jounce bumper. A State Trooper caught Us & instructed Us to "Pull over, You have a broken shock or spring, the vehicle is unsafe to operate". We complied, & He drove off. Once out of sight, We drove to the next exit & bounced all the way back to little Wash.....lol.

This was '83-'84.

oldmopardude

Well-Known Member

scoring will not damage the bar.

However, two conditions can cause the bar to break.

the first is if the lower A frame bushing collapses, causing the housing in the frame to crack and allow the bar to move around and break.

another cause (rarely) but defective bar when manufactured.

However, two conditions can cause the bar to break.

the first is if the lower A frame bushing collapses, causing the housing in the frame to crack and allow the bar to move around and break.

another cause (rarely) but defective bar when manufactured.

My point was, to the regular joe, was it a nick, was it over twisted, was it bent, all anyone knows is it is broken.Lol. “No one knows scientifically”.

There is absolutely a scientific explanation for why that bar fractured.

Maybe no one bothered to have that reason determined, but a materials science analysis could tell you exactly why

So saying that a scratch or a gouge will cause it to fail like that is just a guess.

Yes a metallurgist could determine the cause but most of us are not.

The bar has been there? It’s ether fatigue or a fracture.

If it’s a new bar, it could be poorly made, or a fracture from being dropped or mishandled.

Scoring is an issue if not addressed. That could lead to a fracture. Then there is over stressing the bar. That will lead to failure. I had a set of bars that just simply would not hold up the car anymore. I thought it odd when the second ajustment did t hold. I re adjusted it and over night it sank down. That’s when I pointed my finger at the bars and said, “YOUR FIRED!”

A friend of mine had installed oval track bars into his Duster and tried to raise the car a bit more than what the bars were designed to do. “Snap!” During the night.

Old bars that no longer retain there adjustment

If it’s a new bar, it could be poorly made, or a fracture from being dropped or mishandled.

Scoring is an issue if not addressed. That could lead to a fracture. Then there is over stressing the bar. That will lead to failure. I had a set of bars that just simply would not hold up the car anymore. I thought it odd when the second ajustment did t hold. I re adjusted it and over night it sank down. That’s when I pointed my finger at the bars and said, “YOUR FIRED!”

A friend of mine had installed oval track bars into his Duster and tried to raise the car a bit more than what the bars were designed to do. “Snap!” During the night.

Old bars that no longer retain there adjustment

scoring will not damage the bar.

However, two conditions can cause the bar to break.

the first is if the lower A frame bushing collapses, causing the housing in the frame to crack and allow the bar to move around and break.

another cause (rarely) but defective bar when manufactured.

My point was, to the regular joe, was it a nick, was it over twisted, was it bent, all anyone knows is it is broken.

So saying that a scratch or a gouge will cause it to fail like that is just a guess.

Yes a metallurgist could determine the cause but most of us are not.

Neither of these are true.

It's not a guess to say that a gouge can cause a failure. That is a metallurgic fact. Now, whether a given bar in a given car failed because of a gauge is just a guess, without analysis a broken bar is just a broken bar. Now, if the crack starts out of a set of vice grip gouges, you can be fairly certain what happened!

Torsion bars carry about 90% of their load very close to the surface of the bar. Again, that's physics. That's why there are hollow sway bars, and why they only have to be slightly larger than their solid counterparts to have the same rate. Now, a small scratch isn't a big deal and isn't likely to cause a failure. A gouge, especially one that has a sharp edge and was made with a compression type tool, can absolutely cause a failure. The sharp edge creates a place where forces are localized and concentrated, and a crack can form there and propagate. The other thing is with compression, you can form a harder section of metal. Again, that part doesn't twist like the rest of the bar, which can cause hardening over time and cracks.

Torsion bars aren't fragile by any means, and some nicks and gouges can be dressed so there are no sharp edges and that will be fine. But a deep enough gouge can absolutely cause a torsion bar to fail, and if the damage is deep enough even dressing the damage out could still result in enough weakening of the bar in a localized are to cause problems.

I definitely wouldn't worry about every scuff, scratch or nick. Most will be no big deal at all. But that's a lot different from saying that the bars won't fail if damaged. They can, and they will, if the damage is significant enough. And that doesn't take some giant chunk of metal peeled out of the bar. Just look at the torsion bar chart, and see how a very small change in diameter makes a fairly significant difference in the spring rate of the bar- going from .87 to .89", a .02" change in diameter, is a 10 lb/in difference. That's an 8% difference in rate on that bar.

oldmopardude

Well-Known Member

I am referring to a car driven under normal driving conditions. I am not referring to racing or modified cars. I have been working on mopars since 1966, and I have never seen a bar break from a score.

so I strongly disagree with your concept of what a score is.

bars do go flat, or get badly gouged, and sometimes break as a result. They do get scored, but don't break. and as you said,,a bar is not fragile, so a guy really has to try hard to damage a bar bad enough to break as you describe.

so I strongly disagree with your concept of what a score is.

bars do go flat, or get badly gouged, and sometimes break as a result. They do get scored, but don't break. and as you said,,a bar is not fragile, so a guy really has to try hard to damage a bar bad enough to break as you describe.

I had one break one time on a 71 Dart I had. When I got the pieces out, I noticed there was a long scratch on it that was lined up perfectly with the break. Coincidence? Maybe, maybe not.

I am referring to a car driven under normal driving conditions. I am not referring to racing or modified cars. I have been working on mopars since 1966, and I have never seen a bar break from a score.

so I strongly disagree with your concept of what a score is.

bars do go flat, or get badly gouged, and sometimes break as a result. They do get scored, but don't break. and as you said,,a bar is not fragile, so a guy really has to try hard to damage a bar bad enough to break as you describe.

Good for you. There are multiple accounts of torsion bars breaking on this forum posted by different members in different situations.

I'm also just guessing you've never studied materials science, metallurgy, or engineering. I have. A score can cause a bar to fracture. Whether or not a particular score will, or how deep it really needs to be can be debated. But it's simply a fact of their construction that a torsion bar can fail by being scored. Again, about 90% of the load on the entire bar is carried on the surface and very near to the surface of the bar. It doesn't take much imagination to think about the forces that are exerted on the bars, and how much energy that is being carried in a relatively narrow area.

Probably not!I had one break one time on a 71 Dart I had. When I got the pieces out, I noticed there was a long scratch on it that was lined up perfectly with the break. Coincidence? Maybe, maybe not.

A crack propagating out of damage is a pretty tell tale sign. You'd have to check for inclusions to rule out that the damage just happened to also be in the same place as a inclusion caused during the manufacturing of the bar, but that would be a pretty big coincidence.

-