I just put a freshly rebuilt 727 in my dart, I swaped the automatic valve body for a TCI reverse manual valve body, followed all the instructions. Then I bolted the transmission in and was installing the drive shaft and realized I couldn't turn the drive shaft, I checked it in all gears and I can not get it to spin, even with the drive shaft in pushing the car it won't move, it's like it's stuck in park. Any idea whats wrong?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transmission help

- Thread starter smythge

- Start date

-

Mrmopartech

Well-Known Member

You have incorrectly install the parking paw and not hooked the lever in properly,remove pan and recheck,Mrmopartech

Mrmopartech

Well-Known Member

If the paw was installed incorrectly or could not release correctly it would not turn.So it is some thing else,did you touch the band adjustment at all,install the wrong valve body gasket to cause pressure to be going to the wrong applacation?Did you install the valve body bolts in the correct location,as there are different lengths and torques? Mrmopartech

fishy68

Tyr Fryr's Inc.

Kinda does sound like maybe the reverse band may be too tight. That will cause it. Now that you have started it up and ran it through the gears and shut it down have you tried it again to see if you can spin it by hand? If you still can't spin it by hand I'd say it's probably the reverse band is too tight. What did the valve body mfg. recommend adjusting it at?

And there are no different lengths or torques for the bolts. All are the same. There is also no gasket on a Torqueflite trans. valvebody.

And there are no different lengths or torques for the bolts. All are the same. There is also no gasket on a Torqueflite trans. valvebody.

I'll check the revearse band the valve body instructions said 72" lbs then back it off 2.5 turns. I had a friend do it so I will double check it. and yes there is no gasket on the valve body also the bolts are all the same length and have the same torque specs.

Yep it was the bands, I asked my friend how he adjusted them and he torqued them to 72" lbs but did not back them out, I retorqued them and backed them each out 2.5 turns and the drive shaft spins freely, now I just need to take it for a test drive.

fishy68

Tyr Fryr's Inc.

Glad you got it man!!:thumrigh:

fishy68

Tyr Fryr's Inc.

Sounds like possibly a front band problem. If it's adjusted correctly it could be the servo is leaking. Did you do your air pressure checks along the way? I always do to ensure things are sealing properly. If it is a front band servo problem it wouldn't be a hard problem to fix. Drop the pan and valve body. Air test the servo first to see if it's working with about 20-25 lbs. of air pressure. If it sounds like it's leaking alot you've got a bad seal. Or if the band don't move the seal is bad.

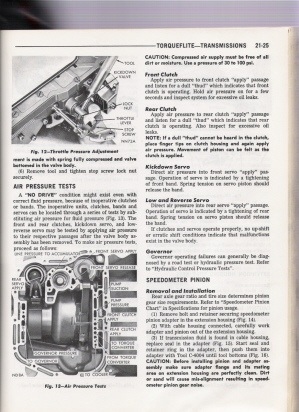

I attached a pix to show where the test ports are in case you don't know. Hopefully it comes out.

I attached a pix to show where the test ports are in case you don't know. Hopefully it comes out.

fishy68

Tyr Fryr's Inc.

Wow that pix really came out little!! The test port for the front servo is the round hole just to the left of the servo piston and just below the top right valve body mounting bolt as seen in the pix. You might also try right clicking on the picture and saving to your images and blowing it up. I do that sometimes with pictures to see them better and then you can also print them off if you have a printer.

BTW: If all checks good with the front servo/band then it's most likely a valve body problem.

BTW: If all checks good with the front servo/band then it's most likely a valve body problem.

I know it is 20/20 hindsight now. But I don't think I would be letting your friend or anybody else for that matter do the delicate adjustments on my tranny. It is one of those jobs that has to be done by one person to make sure everything is done and done correctly. And even then we screw up sometimes.

Jack

Jack

fishy68

Tyr Fryr's Inc.

I agree with Jack. It is a very critical adjustment that can't be guessed at or the trans. wont work right and last. Glad you got it working right now though.:thumrigh:

Good advice, my friend works in a machine shop and builds motors for a living and has rebuilt several transmissions, this was his first 727, so he was not familar with the band adjustments and the chilton manual we had did not say anything about backing the adjuster screws out 2 turns. I have read so many articles on the different ways to adjust bands, inluding some so vague as recommending to be able to just turn the drive shaft. My seems to be very sensititve a little to tight and it felt like the brakes were applied in 3rd gear, little too loose and it slipped all the way through 2nd gear. So after 3 trial and error attempts and finally figuring it out I ended up with the adjuster screw to 72" pounds and backing it 1 3/4 turns it now shifts perfectly into second and into 3rd no overlap between gears and nice firm shifts.

Glad you got it working right smythge. Things like that can get very costly.

Jack

Jack

-