You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Use a press don't be like me axle bearing removal

- Thread starter 65TerrorCuda

- Start date

-

That's not gonna hurt a thing.

Okay, I wont be like you but do I have to use a press.

65TerrorCuda

Well-Known Member

Okay, I wont be like you but do I have to use a press.

Thanks for the lol

I was thinking of oxy torching off the other side just to watch it fall off

No? I felt like an idiot I'll tell you that. New bearing went on fineThat's not gonna hurt a thing.

I feel like an idiot on a daily basis even when I don't do anything. lol

Thanks for the lol

I was thinking of oxy torching off the other side just to watch it fall off

No? I felt like an idiot I'll tell you that. New bearing went on fine

65TerrorCuda

Well-Known Member

You're too hard on yourselfI feel like an idiot on a daily basis even when I don't do anything. lol

Poorly edited bonus video for my buddies here

You're too hard on yourself

Poorly edited bonus video for my buddies here

Very cool, but not near long enough. lol

...and I wish I was hard. At least the wife would be happy. LMAO

65TerrorCuda

Well-Known Member

lol well I know how that isVery cool, but not near long enough. lol

...and I wish I was hard. At least the wife would be happy. LMAO

longer and dustier

That's a super neato little car! What small block is that? I bet it'a really responsive with the little 471 on it.

Ironracer

Gearhead

Me too, Brother Rob!I feel like an idiot on a daily basis even when I don't do anything. lol

65TerrorCuda

Well-Known Member

Thanks! Original 273 0.30 over. It does pretty good and sometimes I have to watch myself. Loads of funThat's a super neato little car! What small block is that? I bet it'a really responsive with the little 471 on it.

That's just badass!Thanks! Original 273 0.30 over. It does pretty good and sometimes I have to watch myself. Loads of fun

Ok so how did you mar the shaft, my guess is you got too aggressive with a cutoff wheel?Thanks for the lol

I was thinking of oxy torching off the other side just to watch it fall off

I use a drill press to drill a 1/4 hole part way in the retainer, then use a chisel at an angle to loosen it up. Then the bearing and everything comes off easy.

pishta

I know I'm right....

No harm. no foul.

Or....

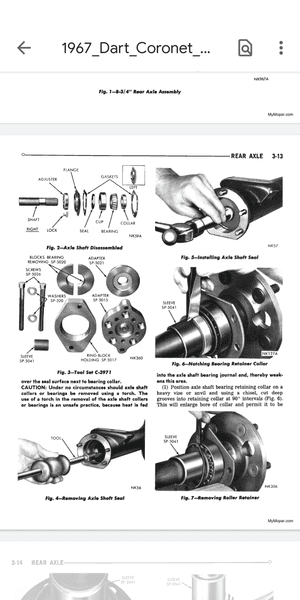

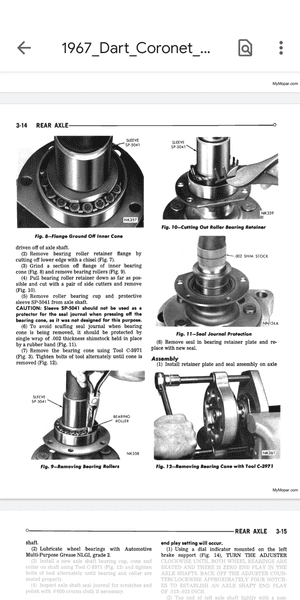

You can follow the procedure in the FSM

You can follow the procedure in the FSM

65TerrorCuda

Well-Known Member

Exactly. Youtube makes it look so easy.Ok so how did you mar the shaft, my guess is you got too aggressive with a cutoff wheel?

Thanks for the all the info and replies! I still need to install the retainer ring which is even tighter than the bearing. Considering heat or maybe a shop with a taller press than mine.

65TerrorCuda

Well-Known Member

Thank you sir!That's just badass!

This sounds like something I will try on the second axle. This metal makes my chisel seem like it's made out of copper lol. USA craftsman tooI use a drill press to drill a 1/4 hole part way in the retainer, then use a chisel at an angle to loosen it up. Then the bearing and everything comes off easy.

I was sweating it man, thank you.No harm. no foul.

Now THAT would suck!DO NOT use a press to remove axle bearings. You can buckle/ warp the axle from the pressure.

Great info, thanks! There's some good techniques in there but certainly haven't seen that double bolt puller thing beforeOr....

You can follow the procedure in the FSM

You can put your axle in the freezer, and warm up the retainer. As I understand the can slip on that way.

You could also make an assembler like the FSM shows.

Or just hand over 50.00 and a 6 pack of beer and have your local shop press them on.

You could also make an assembler like the FSM shows.

Or just hand over 50.00 and a 6 pack of beer and have your local shop press them on.

65TerrorCuda

Well-Known Member

I was considering leaving the axle outdoors but the freezer is a better idea. It's not that huge.You can put your axle in the freezer, and warm up the retainer. As I understand the can slip on that way.

You could also make an assembler like the FSM shows.

Or just hand over 50.00 and a 6 pack of beer and have your local shop press them on.

That and oxy acetylene the ring. Knocking the bearing on wasn't too bad.

Wonder if a big 2 or 3 jaw puller could install the ring? You can see I'm avoiding fabbing tools

67Dart273

Well-Known Member

The "big" parts store I used to work for changed a LOT of axle bearings "back then." We had a shop guy they actually nicknamed "Mike the hammer." I'm not sure his methods were all that "surgical" I've changed my share using the same methods back then.

Generally, we'd torch the outer race enough to get the needles cage and outer race off. Lay it on the rear anvil section of the big *** vise and notch the retainer. Many times you could knock that right off

Then we'd heat the inner race with a torch and beat on it, which would deform it and it would generally knock right off

Again, not that I'm "a bit older", not sure I recommend this. It may warp the axle some or at least deform it slightly out of round. THERE IS a danger (been done) of "missing" and thus damaging the seal surface. then you need a speedie sleeve, "or worse!!"

Generally, we'd torch the outer race enough to get the needles cage and outer race off. Lay it on the rear anvil section of the big *** vise and notch the retainer. Many times you could knock that right off

Then we'd heat the inner race with a torch and beat on it, which would deform it and it would generally knock right off

Again, not that I'm "a bit older", not sure I recommend this. It may warp the axle some or at least deform it slightly out of round. THERE IS a danger (been done) of "missing" and thus damaging the seal surface. then you need a speedie sleeve, "or worse!!"

pishta

I know I'm right....

Warping a 3" bar with a torch would take a LOT of heat! FSM says notch and chisel off.

65TerrorCuda

Well-Known Member

I love hearing this kind of story! Much appreciated and it'll help doing the second side.The "big" parts store I used to work for changed a LOT of axle bearings "back then." We had a shop guy they actually nicknamed "Mike the hammer." I'm not sure his methods were all that "surgical" I've changed my share using the same methods back then.

Generally, we'd torch the outer race enough to get the needles cage and outer race off. Lay it on the rear anvil section of the big *** vise and notch the retainer. Many times you could knock that right off

Then we'd heat the inner race with a torch and beat on it, which would deform it and it would generally knock right off

Again, not that I'm "a bit older", not sure I recommend this. It may warp the axle some or at least deform it slightly out of round. THERE IS a danger (been done) of "missing" and thus damaging the seal surface. then you need a speedie sleeve, "or worse!!"

I did your icy hot technique and the collar fell and bounced off the bearing, settling into place! I was ready with the hammer lol. Check out the frostYou can put your axle in the freezer, and warm up the retainer. As I understand the can slip on that way.

65TerrorCuda

Well-Known Member

Retainer removal 2nd side:

Not 100% sure the driver's side bearing is fully seated. Definitely no side loading though!

Not 100% sure the driver's side bearing is fully seated. Definitely no side loading though!

-