pishta

I know I'm right....

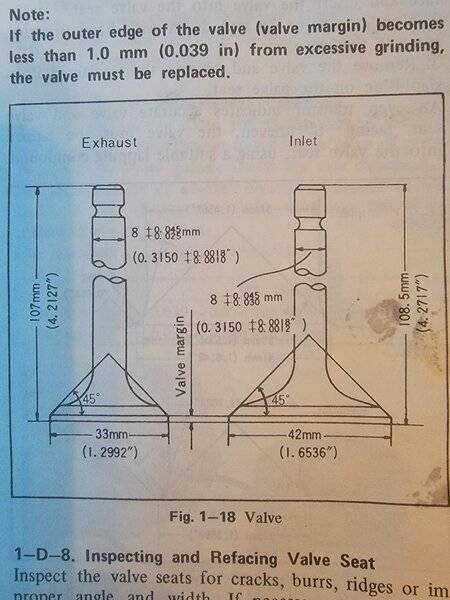

Not Slant specific but applies to all guide installs: What's the stem to guide clearance on a .315 (8mm) valve stem? I'm using a bronze guide and once I pressed it in, I need to ream it and I don't quite know what the spec is for the ID of the guide. In the FSM is says 0.315 +.0018/+.0010. Is this the callout for the guide reamer size? ~0.3160- 0.3168? I've never seen a tolerance with 2 plusses. See Pic