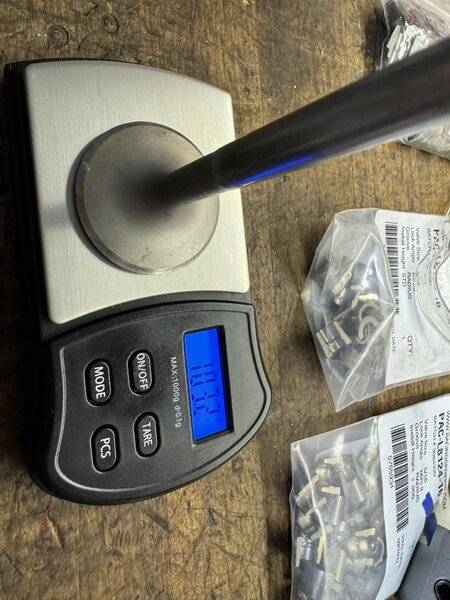

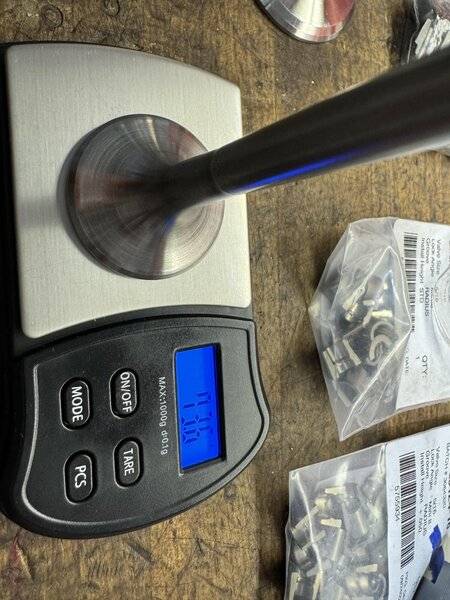

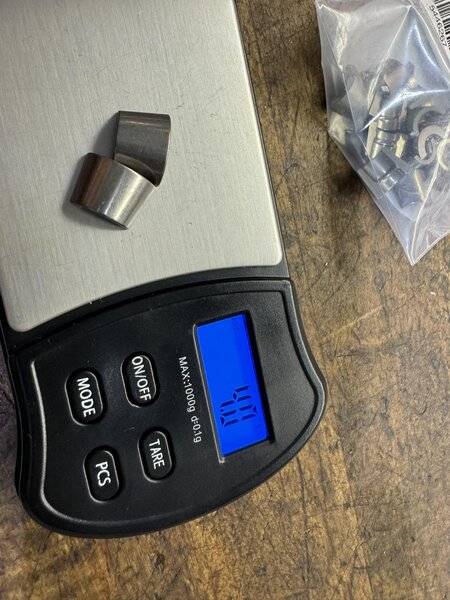

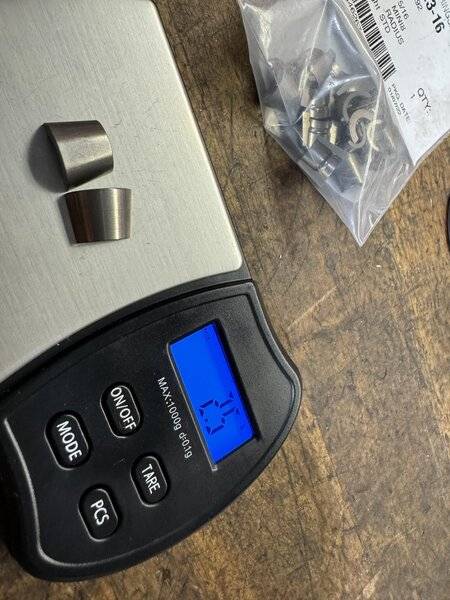

W5 heads are getting closer to being finished. Pictures show the difference in weight of the stock valves vs the ones that we are using. The stock locks vs ti vs the shorties we are using. Chamber volume. Pics of the ports. No flow numbers yet and we might not get any. The time slips will be the proff in the pudding. What started out as me just helping Brett Miller by giving him a head, that I wasn't going to use. Has really turned out to be a blessing. Brett dosen't normally work on stuff like this anymore. Ya'll know that he focuses mostly on the W8 and W9's. The engine these are going on may not fall out of a tree, but they sure look good. BTW Larry Smith did the port work on the heads and intake. God rest his soul. He really was a talented man !

Last edited: