While spending a couple of days with my buddy flowing his heads he was telling me about some custom seat cutters he had. I have been using Neway cutters for the last five years or so and have been limited to 60-45-30 and 15 degree angles. Some of these heads really look like they needed a 70 degree bottom cut so I ordered a couple different 70 degree sizes, a 30, and a nice 15 for top angles. With the guides and needed tooling it came to slightly over 200.00 and a 3-4 week period to make up the kit. Can’t wait to try them out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Well I ordered myself some new valve seat cutters

- Thread starter pittsburghracer

- Start date

-

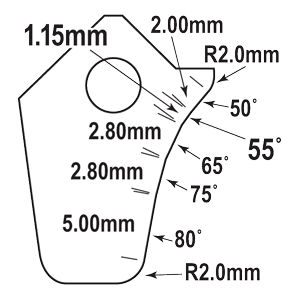

While spending a couple of days with my buddy flowing his heads he was telling me about some custom seat cutters he had. I have been using Neway cutters for the last five years or so and have been limited to 60-45-30 and 15 degree angles. Some of these heads really look like they needed a 70 degree bottom cut so I ordered a couple different 70 degree sizes, a 30, and a nice 15 for top angles. With the guides and needed tooling it came to slightly over 200.00 and a 3-4 week period to make up the kit. Can’t wait to try them out. View attachment 1715679518View attachment 1715679519View attachment 1715679520View attachment 1715679521View attachment 1715679522

What brand are they PBR? I have been close to pulling the trigger on either an old Sioux stone grinder or a set of Neway cutters a couple of times but neither option is inexpensive. Care to share a link and what number cutters we need to handle valve seats in common small block and big block sizes?

yellow rose

Overnight Sensation

WTH???? You didn’t order a 50 degree cutter?????

WTH???? You didn’t order a 50 degree cutter?????

absolutely not. Lol.

What brand are they PBR? I have been close to pulling the trigger on either an old Sioux stone grinder or a set of Neway cutters a couple of times but neither option is inexpensive. Care to share a link and what number cutters we need to handle valve seats in common small block and big block sizes?

I love my Neway cutters and hope to never touch a stone again. This guy is on eBay based in China. Very good email communication back and forth as I came up with what I wanted. Had a late January to mid February shipping date and I got it fedex today. I will try to post a link from my desktop later.

I love my Neway cutters and hope to never touch a stone again. This guy is on eBay based in China. Very good email communication back and forth as I came up with what I wanted. Had a late January to mid February shipping date and I got it fedex today. I will try to post a link from my desktop later.

Cool thanks. Let us know how they do v/s the Neway stuff. I have seen the sets from India on ebay but did not want to buy them as I didn't know anyone with any experience with them. I even thought that if the India set cutters did not work well that they maybe could accept cutters for a Neway seat cutting head.

yellow rose

Overnight Sensation

Will he make a 50????

Pretty sure it was listed but I think he will custom make anything. I will post better info tomorrow. The cutters are fixed and not replaceable like the neway cutters are

famous bob

mopar misfit

I cant believe anyone would want a grinder , or even think about it , no comparison !!

Maybe a lawn mower head ?!

Maybe a lawn mower head ?!

Like Woody at Radar's shop says, "we don't machine heads with a rock"! (they have a Serdi) LOL

Cuda416

Well-Known Member

Curious what's needed to use these. I seem to remember, as a young lad, working with the machinist at the auto store worked at a sort of "slow drill press" looking thing that turned the carbide pretty slow. Could it be done by hand with a speed wrench?

I cant believe anyone would want a grinder , or even think about it , no comparison !!

Maybe a lawn mower head ?!

Well, there was a time when most all reconditioned valve seats were done with a grinder. Some were still able to get pretty good results using them. Its kind of like bondo. In the wrong hands you can wind up with a mess for sure, but if used properly there is nothing wrong with it. That said the Neway multiple angles on one head cutters are looking pretty sweet.

Curious what's needed to use these. I seem to remember, as a young lad, working with the machinist at the auto store worked at a sort of "slow drill press" looking thing that turned the carbide pretty slow. Could it be done by hand with a speed wrench?

Neway has a t handle that comes in their kits. I would assume something similar in PBR's new purchase. They also sell a motorized drive for them as well.

Cuda416

Well-Known Member

Neway has a t handle that comes in their kits. I would assume something similar in PBR's new purchase. They also sell a motorized drive for them as well.

Ah, so with the "T" handle it's sort of like driving a tap?

My son uses a Serdi styles they are removable multi angle bits. He has up to 6 angle you can go to 7. Also he puts in an under cut.

Neway has a t handle that comes in their kits. I would assume something similar in PBR's new purchase. They also sell a motorized drive for them as well.

I have the drive system for my Neway cutters but have been doing them by hand for years. A few turns by hand and proper fluid from Goodson and you are moving on. I am still kicking around buying this

Here's a link to the guy I dealt with and he has excellent reviews. He communicated great by email anytime I had a question or wanted pricing. Do your homework if and before you order as many of the kits are for many or different sized valve guides. I didn't want 5/16, 7/16, or 1/2 inch pilots so why but them. I didn't want cutters to do rototillers or go-carts so why buy them. I paid a little more by piece to get the ones I wanted without the fluff. Remember he's from India so don't expect IMEADIATE responses as it may be night in his area.

24x Valve Seat Cutter Set Carbide Tipped 12X CUTTER HEADS 8X GUIDES 2X ARBORS | eBay

24x Valve Seat Cutter Set Carbide Tipped 12X CUTTER HEADS 8X GUIDES 2X ARBORS | eBay

MOPAROFFICIAL

Oogliboogli

Im glad you did .. because ive had my eye on them for a while but am concerned they wont last or cut a hard seat/powdered or what not... so looking forward to your report! TiaWhile spending a couple of days with my buddy flowing his heads he was telling me about some custom seat cutters he had. I have been using Neway cutters for the last five years or so and have been limited to 60-45-30 and 15 degree angles. Some of these heads really look like they needed a 70 degree bottom cut so I ordered a couple different 70 degree sizes, a 30, and a nice 15 for top angles. With the guides and needed tooling it came to slightly over 200.00 and a 3-4 week period to make up the kit. Can’t wait to try them out. View attachment 1715679518View attachment 1715679519View attachment 1715679520View attachment 1715679521View attachment 1715679522

Here’s a couple pictures assembled to give you a better idea. This is the fluid I use for seat cutting.

famous bob

mopar misfit

Here’s a couple pictures assembled to give you a better idea. This is the fluid I use for seat cutting. View attachment 1715679983View attachment 1715679984View attachment 1715679985

I used to work for dresser ind. , the pipeline engines compressors had poppit vales in disc shaped housings , with around 27-30 (cant remember for sure) , In each disc , had to grind those seats for more years than I want to remember , hated every minute of it , probly ground more than u guys have seen , altho they wern`t performance type stuff , some times 30-40 discs in a single compressor , 4 to 8 compressors on each engine , depending on how big it was .

They had v-16 and v-20 engines that were bigger than a lot of buildings , they were so big they couldn`t be shipped assembled , much less w/ the compressors bolted on the side of them. Best thing I ever did was get away from that place !

If I need any head work done , I have a friend that has a serdi machine -------------

I used to work for dresser ind. , the pipeline engines compressors had poppit vales in disc shaped housings , with around 27-30 (cant remember for sure) , In each disc , had to grind those seats for more years than I want to remember , hated every minute of it , probly ground more than u guys have seen , altho they wern`t performance type stuff , some times 30-40 discs in a single compressor , 4 to 8 compressors on each engine , depending on how big it was .

They had v-16 and v-20 engines that were bigger than a lot of buildings , they were so big they couldn`t be shipped assembled , much less w/ the compressors bolted on the side of them. Best thing I ever did was get away from that place !

If I need any head work done , I have a friend that has a serdi machine -------------

I’m kinda stubborn about asking for help or favors sometimes to a fault but that’s me. I’ve never paid to wash, wax, detail, or change oil in any of my cars ever.(except if my sons needed the money). I’m kinda nutty.

Those the seats you cut? How good does it work?Here’s a couple pictures assembled to give you a better idea. This is the fluid I use for seat cutting. View attachment 1715679983View attachment 1715679984View attachment 1715679985

MOPAROFFICIAL

Oogliboogli

I like stones, they're what i use.. but they sure are messy.

Those the seats you cut? How good does it work?

I have zero valve work right now. The speedmaster heads flowed great on the intake side for Ethans heads and they lapped in nice on the ones I checked so far. I didn’t check the exhaust side on Ethans heads yet but the set I ported last year worked so good I was afraid changing it could mess it up. I may be awhile till I try them out.

I like stones, they're what i use.. but they sure are messy.

I did it like that for awhile and still have my equipment. My stone holder needs replaced but I hate doing it like that so hopefully I never touch that stuff again. That’s dirtier than porting aluminum heads. Notice I said aluminum not cast iron. Lol

-