So, I'm going to have to use spacers for my Dart. There was no way around it. I'll be running a 0.200" spacer (relatively thin) front and back and I was wondering what the general rule of thumb is for needing longer studs. I was told you needs at least 7 turns on the lug nut? Should there be a certain length of threads showing prior to installation of the wheel? Thanks for your help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel Studs and Spacers

- Thread starter MuuMuu101

- Start date

-

Remember that time some random dude swooped in on your thread and kinda hjacked it without helping out at all?

Here's the situation I'm dealing with- 10mm spacer results in not much thread showing (see picture)

I heard you need the width of the stud in thread depth as a rule of thumb, though 7 turns sounds more accurate. I don't even know if I've go that.

And the problem I've found with studded spacers is that they only come in wider width than will fit...

Here's the situation I'm dealing with- 10mm spacer results in not much thread showing (see picture)

I heard you need the width of the stud in thread depth as a rule of thumb, though 7 turns sounds more accurate. I don't even know if I've go that.

And the problem I've found with studded spacers is that they only come in wider width than will fit...

ragtopfury

Well-Known Member

Put an original "open" lug nut on the original stud without the spacer behind the wheel and see what it looks like. You'll have your answer. Or if you are adding a .2 inch spacer, get studs that are .25 inch longer. Seems a no-brainer to get studs at least as much longer as the amount of spacer you are using.

Milspec to go by have the diam of the bolt/stud showing past the locking device. so a 7'16 stud = 7/16 showing. hope it helps

famous bob

mopar misfit

Milspec to go by have the diam of the bolt/stud showing past the locking device. so a 7'16 stud = 7/16 showing. hope it helps

since the stud sticking out of a nut won`t increase strength, I`d be happy w/ a full nut of threads, any shorter and you will not be at full strength. JMO

since the stud sticking out of a nut won`t increase strength, I`d be happy w/ a full nut of threads, any shorter and you will not be at full strength. JMO

This isn't true. You don't necessarily need the nut to be completely full of threads to reach full strength.

Fastenal has a really great page on thread design ( click here for link), so rather than start pulling out my engineering books and formula's I'm just going to quote them. The bit on thread strength is at the bottom of the page.

For carbon steel fasteners (including tapped holes) the length of engagement would be limited to approximately one nominal diameter (approximately 1-1/2 times the diameter for aluminum). After that, there is no appreciable increase in strength. Once the applied load has exceeded the first thread's capacity, it will fail and subsequently cause the remaining threads to fail in succession.

So, on a 1/2-20 stud like the BBP wheel studs, you only need ~1/2" of engagement for full strength. Depending on the nut, that may not be anything close to having all the threads filled. That's a generalization too, if you break out the formula's and 1/2" fastener data (calculator here) you end up getting ~.44" for minimum engagement on a 1/2-20 bolt, which is actually like 8.7 turns. That's more than the "rule of thumb" for lug nuts that says 5-7 turns, but keep in mine that the "rule of thumb" doesn't take into account diameter or thread pitch, it would be fewer turns for a 7/16"-20 lug nut (like the SBP studs).

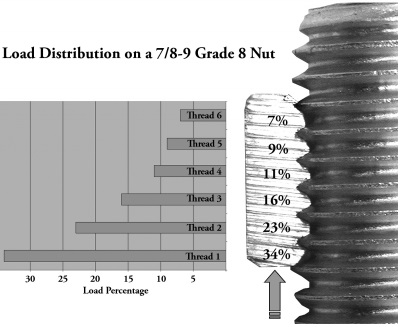

Here's a graphic that depicts the break down for a 7/8"-9 nut. The numbers would be a little different for 1/2"-20 but you get the idea (and the idea of where the 5-7 turns "rule" comes from). In this example, at only 5 threads you're at 93% of your total strength.

-