No, I meant what I said. I said it that way, BECAUSE gross lift will be short because of the pushrod angle. In other words, it will be short the CALCULATED gross lift when including the rocker ratio. I left "all that" out for the sake of discussion, since "we don't know" what "all that" is since discussion of rockers and rocker ratio was not involved. Get it?RRR,

You are forgetting 'relativity'. Firstly, the numbers quoted are NOT lobe lift, they are valve lift. The numbers on a cam card that refer to valve lift are theoretical valve lift, lobe lift multiplied by rocker ratio. Several factors will influence the measured valve lift that can be more or less than the calculated ratio. Relativity. If lifter/prod angle affects the measured valve lift, it will do so for all cams used in that engine, not just one.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Block Chrysler Racer Brown camshafts

- Thread starter Abodysloth

- Start date

-

I've never seen this in print in any publication anywhere at all. That includes all of my OLD Hustle Stuff books, all of my Direct Connection literature and all of my Mopar Performance information. Can you supply a source for this?Cam Dynamics & Crane also supplied DC cams.

RRR,

Yeah I do 'get it'......have done, for a long time.....

This is what you said in post #21:

"That's 0.040" less lift at the LOBE".

It is not 040 less lobe lift, it is 040 less lift at the valve. Post #5 makes it clear, unless you think a FT cam for one of these engines can have 600 lobe lift....

Yeah I do 'get it'......have done, for a long time.....

This is what you said in post #21:

"That's 0.040" less lift at the LOBE".

It is not 040 less lobe lift, it is 040 less lift at the valve. Post #5 makes it clear, unless you think a FT cam for one of these engines can have 600 lobe lift....

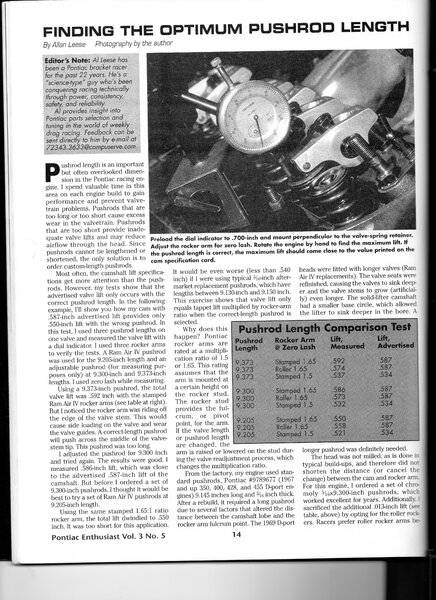

This may be of interest. How prod length changes valve lift. Very accurate test, done on a Pontiac V8, but the same principles apply to other engines. The factory correct length PR for this engine was 9.205". Notice the 0.042" difference in valve lift with 1.65 stamped rockers between PR lengths.

Ok, you got me. So I said it wrong. THE PUSHROD ANGLE WILL STILL KNOCK SOME OFF TOTAL LIFT WHICH WAS MY POINT. Ok?RRR,

Yeah I do 'get it'......have done, for a long time.....

This is what you said in post #21:

"That's 0.040" less lift at the LOBE".

It is not 040 less lobe lift, it is 040 less lift at the valve. Post #5 makes it clear, unless you think a FT cam for one of these engines can have 600 lobe lift....

.....and thanks for the camshaft info. That's something I've either missed all these years (very likely) OR has not been in print in any of my literature (less likely).RRR,

CD & Crane cams.

From my Mopar Perf book P4452790.

P. 139 SB cams:

P4349243 C.D. Stock Cheater

P3690795 Crane

P4007278 Cam Dyn

P4007509 Cam Dyn

Newbomb Turk

Well-Known Member

Turk,

I understand the realities of valve train better than you do, as your post #22 exposes the reality.

The lobes I quoted were using the Ford 875 lifter. They have less total lift & less area under the curve than lobes designed for the Chrys 904 lifter & are not on the ragged edge. So the valve train with the quoted lobes will have an easier life than lobes designed for a 904 lifter.

To further educate you, here are two examples, UltraDyne lobes:

One is the 875 lobe I quoted in post #5. 272 @ 050, 602 valve lift.

The UD lobes for 904 lifters stop at 263 @ 050, so I will use '263' for the comparison.

The equivalent 875 lobe, 263 @ 050 has 0.590" lift. The 904 lobe has 3* more duration at 0.200" lift [ 181* ] than the 875 lobe & 0.597" lift.

It has more area under the curve.

As for lobe lift & valve control, the UD sol lifter lobes go as high as 0.635" lift with 1.5 rockers or 0.720" with 1.7 rockers.

Using your 'logic', nobody would run roller cams with their extra lift & faster acceleration rates because of valve train stability issues.

Did you read what I said about spring loads and flat lifters? Talking about roller cams when the topic is running the most aggressive lobe in the book with flat lifters are two entirely different things.

Again, you don’t always need or want the most aggressive lobe.

PRH

Well-Known Member

I rarely use the most aggressive lobes available……. In anything.

I've seen a lot on here do it and some come back whining about how noisy their valve train is. I promise you that you can find my advice and a sctna handful of others advising against it, yet "us few" got argued into oblivion by those "who know better". All I know is, I love the way the Crane Fireball runs and sounds in the Ford 400 in Gladys. LOL Old school goodness at its best.I rarely use the most aggressive lobes available……. In anything.

Old school that works for fun on the street. I sold many of those for $49.95. There's a lot of threads that start out about a nice running street small block and often end up building a maximum horsepower mill. Frustrating.I've seen a lot on here do it and some come back whining about how noisy their valve train is. I promise you that you can find my advice and a sctna handful of others advising against it, yet "us few" got argued into oblivion by those "who know better". All I know is, I love the way the Crane Fireball runs and sounds in the Ford 400 in Gladys. LOL Old school goodness at its best.

I saw where you made a post about....what was it? TRW I think? cams? THey had LOTS of cams back in the day and some pretty good ones. TRW, Melling, Sealed Power and on and on.....and BACK THEN their grinds were all "a little" different. Now, all those generic cams are all the same grinds. But you're right. I sold a lot of them too about that price point and they always worked. I don't remember anyone wiping lobes. Ever.Old school that works for fun on the street. I sold many of those for $49.95. There's a lot of threads that start out about a nice running street small block and often end up building a maximum horsepower mill. Frustrating.

Yes, we had TRW parts, some of the best around. Their TP cams were a lot of fun. I mentioned a 300°/.500 lift HFT that was an animal back then. I worked there when we picked up the Comp Cams line. It was good stuff back then. Yep, no flat lobes or bad lifters.I saw where you made a post about....what was it? TRW I think? cams? THey had LOTS of cams back in the day and some pretty good ones. TRW, Melling, Sealed Power and on and on.....and BACK THEN their grinds were all "a little" different. Now, all those generic cams are all the same grinds. But you're right. I sold a lot of them too about that price point and they always worked. I don't remember anyone wiping lobes. Ever.

Yeah, that was it. I also lump General Kenetics and Alliance in too. Never had a single problem with any of those and we ran a ton of them on the dirt track. I always wonder WHY guys back then bought Crane, Comp or any other main stream brand, because they weren't winnin anymore races than we were.Yes, we had TRW parts, some of the best around. Their TP cams were a lot of fun. I mentioned a 300°/.500 lift HFT that was an animal back then. I worked there when we picked up the Comp Cams line. It was good stuff back then. Yep, no flat lobes or bad lifters.

Hippy

New Member

The Hemi Darts also favored Racer Brown camsRacer Brown arguably has the best grinds for Chrysler engines. A lot of these younger guys probably don't know that Racer Brown supplied ALL the camshafts for Chrysler back when it was Direct Connection. All those grinds are still available through Racer Brown.

Early Racer Brown throughout this vid - nothing to do with this post - just entertaining - if you have his cam you'll recognize the logo

Demonic

Well-Known Member

Yes, we had TRW parts, some of the best around. Their TP cams were a lot of fun. I mentioned a 300°/.500 lift HFT that was an animal back then. I worked there when we picked up the Comp Cams line. It was good stuff back then. Yep, no flat lobes or bad lifters.

A friend of mine built a 318 with the TRW 340 repo cam. I don't know if it was the 68 manual spec, but it ran like a scalded dog. You never would guess it was 22 ci down with a set of 3.91's and a stick.

Love to hear those stories. Never a guess as you whether the parts were good. Lots of heavy hotter stock car engines were built with TRW parts.A friend of mine built a 318 with the TRW 340 repo cam. I don't know if it was the 68 manual spec, but it ran like a scalded dog. You never would guess it was 22 ci down with a set of 3.91's and a stick.

I’m guessing some of you guy wouldn’t have ran the 332 duration, [email protected] cams with .750 lift that we ran back in the 1980’s with junk parts. Lol

I’m guessing some of you guy wouldn’t have ran the 332 duration, [email protected] cams with .750 lift that we ran back in the 1980’s with junk parts. Lol

not on the street

not on the streetIt's fun how this thread has gone so many directions.

OP: I have this cam, anybody run it and what's it worth?

OP: I have this cam, anybody run it and what's it worth?

not on the street

That cam had manors like you wouldn’t believe. With both a 1050 dominator and a weiand tunnel ram with two 750 Holleys.

332 duration. The valves were open most of the time. It's a wonder you had enough compression for combustion.That cam had manors like you wouldn’t believe. With both a 1050 dominator and a weiand tunnel ram with two 750 Holleys.

332 duration. The valves were open most of the time. It's a wonder you had enough compression for combustion.

When I was laid off for the mill I got a job doing R &R work at a transmission shop. They were all dirt track racers. Well I picked up one of their Ragizines and that’s exactly what it said. How the heck do these drag cars start. Lol

And how many times have you seen the "experts" on here say the 340 cam is WAY too big for a 318? It's like anything else. Match the combo and it'll run.Love to hear those stories. Never a guess as you whether the parts were good. Lots of heavy hotter stock car engines were built with TRW parts.

-