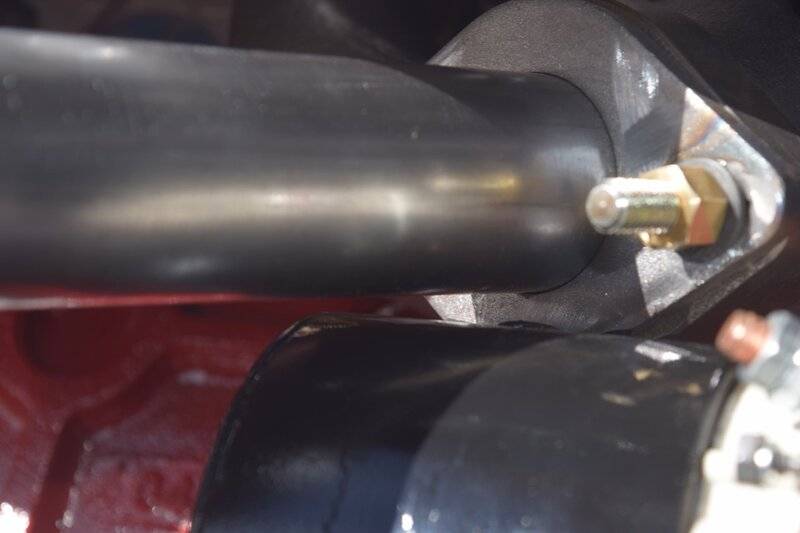

Hate it when I get a gouge in my trunion.....NOS on order from eBay. The yoke on the other end was bent. Machine shop got it closer and a new joint.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

New NOS trunnion housing dropped off at the machine shop to finish up the driveshaft restoration. New AMK bolts for the starter look snazzy.

After running the model it was clear that 1 3/4" pipe was no different than 2 1/4" pipe from the Dutra Duals to the "Y" and with that knowledge an idea popped into my head. I bought 1 3/4" plates for the Dutras and various mandrel bent pipes for making headers from Summit. They were 3", 4", 6" and 8" diameter and a 5' piece of pipe. A little thinking and more thinking then a run into town before the welding shop closed to get some shielding gas I made the first cut. All I need to do it the easy part out past the transmission and the "Y" is now on order so we should have this done next weekend.

Yes the starter can be removed, yes the steering gear can be removed, yes I will be making shields for the starter, cooler lines and steering gear in the future.

After running the model it was clear that 1 3/4" pipe was no different than 2 1/4" pipe from the Dutra Duals to the "Y" and with that knowledge an idea popped into my head. I bought 1 3/4" plates for the Dutras and various mandrel bent pipes for making headers from Summit. They were 3", 4", 6" and 8" diameter and a 5' piece of pipe. A little thinking and more thinking then a run into town before the welding shop closed to get some shielding gas I made the first cut. All I need to do it the easy part out past the transmission and the "Y" is now on order so we should have this done next weekend.

Yes the starter can be removed, yes the steering gear can be removed, yes I will be making shields for the starter, cooler lines and steering gear in the future.

Looks good to me. May get them ceramic coated to reduce the heat.

BobW

Curmudgeon At Large

Get the inside C-coated as well, it helps pull the heat down the pipes.Looks good to me. May get them ceramic coated to reduce the heat.

View attachment 1715622723 View attachment 1715622724 View attachment 1715622725 View attachment 1715622726 View attachment 1715622727

Get the inside C-coated as well, it helps pull the heat down the pipes.

I was looking into that last night. Agreed.

Exhaust should be done this weekend so I can get it to the ceramic coating place next Tuesday for hopes of getting it back by Thanksgiving week.

Absolutely gorgeous work !

This is a show winner !

Congrats

This is a show winner !

Congrats

to about where they end now. Not sure what you mean with the clamps. I’m welding it to the Y behind the transmission crossmember then an Accurate Exhaust past that.nice. how far back are you going to have coated and what are you using for clamps?

Last edited:

Jim, have you toyed with the idea of a later model mini starter for clearance on the exhaust?

guess i meant the "past that" since it's all going to be one pipeto about where they end now. Not sure what you mean with the clamps. I’m welding it to the Y behind the transmission crossmember then an Accurate Exhaust past that.

Last resortJim, have you toyed with the idea of a later model mini starter for clearance on the exhaust?

I was just curious I know that the mini starter cured a lot of my heat soak problems on the 416 in the race car.

More work and some bracket fabrication. Last batch of pipe parts coming today so I can finish it up.

mygasser

Well-Known Member

are you going to header wrap the down pipes (from the steering box down) to protect the trans' cooler lines from heat? i know you mentioned ceramic coating which helps but they sure look close.

neil.

neil.

are you going to header wrap the down pipes (from the steering box down) to protect the trans' cooler lines from heat? i know you mentioned ceramic coating which helps but they sure look close.

neil.

Photos make it look much closer than it really is.

Mineallmine

Well-Known Member

Looks amazing. Are you planning to put rubber grommets around the transmission cooling lines at that bracket you fabbed up or tack them to it? If you don't you might run the risk of them vibrating and wearing through. I personally would open the holes up slightly and install rubber grommets.

More work and some bracket fabrication. Last batch of pipe parts coming today so I can finish it up.

View attachment 1715625748 View attachment 1715625749 View attachment 1715625750 View attachment 1715625751 View attachment 1715625752 View attachment 1715625753 View attachment 1715625754 View attachment 1715625755

BobW

Curmudgeon At Large

LOL, I just this morning ordered a grommet selection to fit some holes I drilled as I'm starting to prep for paint!Looks amazing. Are you planning to put rubber grommets around the transmission cooling lines at that bracket you fabbed up or tack them to it? If you don't you might run the risk of them vibrating and wearing through. I personally would open the holes up slightly and install rubber grommets.

View attachment 1715626200

Good idea on insulating the cooler lines from vibration.

Mocked up.... the wind is whipping today and tomorrow so not sure I can get it welded up this weekend. It may be a good thing since I REALLY should put this under the car and make sure it all works good before I get the pipes coated..... I am not sure I can work on the transmission from the bottom but since it is a /6 a lot can be accessed from the top anyway... I matched the angle for the stock pipe exiting the rear of the transmission cross brace so it should be easy to tap into the factory type 2.25" system I have coming from Accurate Exhaust.

Next is O2 sensor fittings so I can adjust the AFR for each carb and then think about heat shield mounting locations in a few key places.

Next is O2 sensor fittings so I can adjust the AFR for each carb and then think about heat shield mounting locations in a few key places.

Not sure if you would like the look, but Cool It and DEI makes nice sleeves to cover lines and the starter.

I am looking at a few of those items right now.

I had my pipes all layed out just like you, but the exhaust shop I took it to did not follow what I wanted exactly. I should have cut the pipe myself. Live and learn.

You have Dutras too?

-