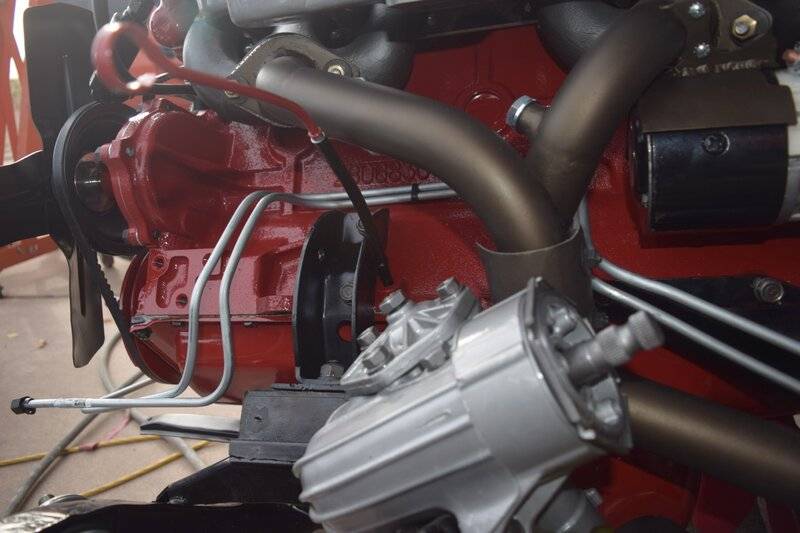

The flat spots on the carbs are where you drill for ported and non ported vacuum. Who will tell me the length of the tube so I can get that in? AMK vacuum fitting so no more 3 reducer Frankenstein adapter. Distributor cover installed. Groovy sticker for the oil filter after the break-in oil is changed. New oil and water sensors installed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1963 Dodge Dart 270 Convertible for the Wife

- Thread starter Jim Kueneman

- Start date

-

Got one vacuum nipple installed then things went sideways... This is a 5mm x 0.8mm thread with a 1/16" hole into the bore.... Need to take the other one to the machine shop to get done with better tools. Someone on Facebook finally gave me the measurement of 2.75" for the dipstick tube. Cut it, installed it and with 4 quarts of oil in the pan read exactly full! AMK makes nice motor mount bolts with attached washers. On the LCA don't tighten those nuts till after you have the torsion bars adjusted up. Laid out the exhaust and it is very close so I finished up the collector.... I have no idea if I can get those pipe out now they are connected.... I hope I never have to. The driveshaft is restored with NOS parts and my custom exhaust is very close to matching the factory exhaust... minimal work to get it connected to the Accurate Exhaust 2.25" center pipe after the power train is installed.

Last edited:

So close yet so far.... here is the disaster of breaking a 1/16 drill bit in the second carb.....

Your detail to work is 2nd to none. Amazing!

- Joined

- Mar 17, 2018

- Messages

- 15,181

- Reaction score

- 35,773

Arghh broken bit! On bright side there is not a person on this forum that wouldn’t love to have your problem. Totally cool build! Great job to your whole family.

Thank goodness.... I was going bat crap crazy imagining that somehow a nut fell into a head port or something... when installing the manifolds I was missing a nut and it was driving me crazy but I just picked up another and moved on.. after that I was having nightmares about the original in some horrible place.... the power of photos.... there are 13 studs total with the end two the special castle nuts so there should have been 11 in my stash... counting.... 1..2..3..4..5.....10! I was missing one from the start!

mygasser

Well-Known Member

shame the oil filter sticker isn't like a fridge magnet so you could swap it over each time you do a filter change.

neil.

neil.

Rolled my own with 2 sockets. The rolled edge will keep the fabricated bracket from cutting through the oil cooler lines. Torque converter time... use blue locktite and torque... Upsy-daisy.... I did not take many photos putting it in as most of the time you are on your back.....

Tons of details putting it back in make it look clean.. the 1968 B-Body starter cable is PERFECT as was the 1968 B-Body neutral safety switch wire from M&H. Transmission cables all snapped in and adjusted ready to roll.... Double check you tightened everything. You don't torque the LCA nut until the LCA is compressed with the torsion bar. Boy the edge of the front cleaner kisses the cross brace in the hood. Need to look for a air filter that is not quite as tall.

First early A Body radiator Bob said he has done... beautiful and perfect fit. Just some glamour shots.... Next is getting the exhaust finished and hopefully Dave will have the carb fixed for me by Friday.

" For the wife" Yeah, muh huh. lol

" For the wife" Yeah, muh huh. lol

Who?

slants give you so much room to work. you can just about hook up the starter from a lawn chair

test drive before xmas?

Hopefully

I am done laying on my flipping back! Accurate Exhaust modified to meet up with my collector.. I needed to do a little jack tweaking of my pipes as they started to head down at the end  . Sucked but no harm done other than bruised ego... The Accurate Exhaust uses such heavy gauge you have to really attack the clamps... got a little to rambunctious on one of them.... Restored original driveshaft in with NOS parts. Parking brake adjusted and she is on the ground under her own full weight for the first time in over a year! Done for the day, need to help around the house for tomorrow.

. Sucked but no harm done other than bruised ego... The Accurate Exhaust uses such heavy gauge you have to really attack the clamps... got a little to rambunctious on one of them.... Restored original driveshaft in with NOS parts. Parking brake adjusted and she is on the ground under her own full weight for the first time in over a year! Done for the day, need to help around the house for tomorrow.

Nice cool day finally so it was nice in the garage. Did the hillbilly alignment to allow us to test drive it and get it to town for a real alignment without tearing up the tires too much... The RH tire was hitting the fender when turning and I torqued and bent it as much as I dared... I think the fronts should have 195's instead of 205's... No harm done as the 205's can go on the Duster when it needs tires if I decide to order the narrower ones. Steering column in in and wheel centered. The DMT kit did not have the exact '63 gasket but by cutting a 4th hole it all worked out... Installed the freshly chromed horn ring. Need to figure out how to restore the center piece now....

The well liner I bought is not quite right.. the early A ragtop expert says only Legendary liners are correct especially for the '63 as it has a different liner, top and boot cover than '64 and up... I decided to pull the threads on the rolled edge along the pinch and use that fold as the marking line. It sets down in deeper and does not have a wad under the pinch rail... it will work for now. I may order a Legendary.... someday as it will take 6 months to get it anyway.

Dave at the machine shop fixed my broken bit and the carbs are done. Found a Wix filter that is the right diameter and 3/4" shorter for the front filter to help gain hood clearance. It will look cool with a step from the front to rear filter.

mopowers

Well-Known Member

Looking good! What'd you use for the rubber isolater around the steering column, where it mounts to the dash frame?

Looking good! What'd you use for the rubber isolater around the steering column, where it mounts to the dash frame?

The original rubber inner tube was still there. Just cleaned and reused it. You can see where the old notch was for the pin in the clamp on the backside... I put it on backwards and was not about to take it back apart but after this photo I regret that

Coming right along! Nice work, Jim!

Pushed her outside so I could open the door and work on the throttle linkage. Throttle linkage all functional and ready for carb synchronization. Hooked up a few minor items like the fuel line, Pertronix 12V line and then topped off all the fluids.... so does it run?

Enjoy....

Dartsun

Mopar Dude

This has been my favorite slant six build on the forum. Jim this car is amazing

-