(Also available for your viewing pleasure at FBBO)

Hi guys, follow this link to another of Joey's great sites, and you can read a little about my first rebuild of the '68 A100 pickup.

https://www.fortrucksonly.com/truck...ibute-to-the-little-red-wagon-pic-heavy.4179/

Not so much in words, but I am happy to answer questions about the process. As with any restoration or rebuild, there are always things that can be improved upon, and this truck is no exceptions. It really was a 90 day build, and it was ready only hours before setting off to what has become a very famous annual event - The Whangamata Beach Hop. Held every year around Easter time'ish, it draws car nuts from all over the world, and showcases a lot of new builds. There is always something new that opens eyes, and gives great inspiration.

This year has been no exception. I have been holding something back from the masses here, and have only been sharing this with a very tight bunch of friends - guys who I can rely upon for solid advice and vision. Don't feel left out....I wanted this to be totally off the radar and low key just on the off chance something went bad. And besides, with too many differing opinions, it would only serve to confuse me, and possibly make me do something irrational here on site.

And besides, with too many differing opinions, it would only serve to confuse me, and possibly make me do something irrational here on site.

So, I am going to give a shout out to the guys involved....I'm sure they won't mind - (in alphabetical order) @Budnicks @conv67bdere @Ghostrider 67 @HEMI-ITIS @MarPar @moparnation74 @Richard Cranium @super-bee_ski

These guys have become good friends and I know I can rely upon the information they share - thanks guys.

Second shout out is to a Vendor here - @Johnny Mac and his team at BluePrint Engines in NE. I started talking with Johnny at the start of this year....and asked him to keep it to himself Johnny guided me through what became a hassle-free purchase and an all round pleasant experience. I selected the engine combination I wanted, and Johnny put his team to work on building it for me. The trouble with trying to build an engine in NZ these days is quality and supply of parts. Unless you have someone trustworthy enough to do the research for you, and actually build the engine in a timely manner, it just becomes another headache. BluePrint Engines took all the problems away for me. I am more than happy to recommend them to anyone wanting the easy route to re-powering their car....or truck.

Johnny guided me through what became a hassle-free purchase and an all round pleasant experience. I selected the engine combination I wanted, and Johnny put his team to work on building it for me. The trouble with trying to build an engine in NZ these days is quality and supply of parts. Unless you have someone trustworthy enough to do the research for you, and actually build the engine in a timely manner, it just becomes another headache. BluePrint Engines took all the problems away for me. I am more than happy to recommend them to anyone wanting the easy route to re-powering their car....or truck.

Thanks Johnny.

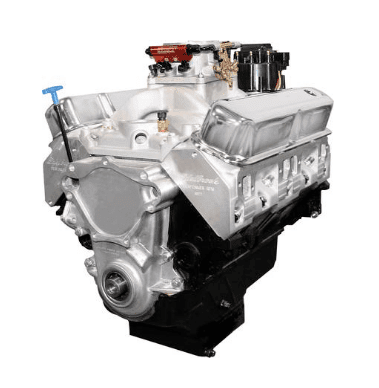

Here it is - the engine I chose.....

BluePrint Engines 408CI Stroker Crate Engine | Small Block Chrysler Style | Dressed Longblock with Fuel Injection | Aluminum Heads | Flat Tappet Cam

The type of EFI changed just before I purchased, so I am now the proud owner of a Holley Sniper system. Man it is way better than any carb system I have ever had. Once you get to understand how these work, there is no way you could ever go back. My buddy Cliff is so impressed, he is looking at putting a Sniper in his Ram.

Choosing the 408 was a no-brainer really, as it slots straight into where my 360 was, and the original mounts and brackets, transmission...everything just bolts back up together.

Sure, I made a few mods along the way....but who doesn't?

More about the mods in subsequent posts.

Rest assured....the engine is awesome, and way beyond my expectations.

Hi guys, follow this link to another of Joey's great sites, and you can read a little about my first rebuild of the '68 A100 pickup.

https://www.fortrucksonly.com/truck...ibute-to-the-little-red-wagon-pic-heavy.4179/

Not so much in words, but I am happy to answer questions about the process. As with any restoration or rebuild, there are always things that can be improved upon, and this truck is no exceptions. It really was a 90 day build, and it was ready only hours before setting off to what has become a very famous annual event - The Whangamata Beach Hop. Held every year around Easter time'ish, it draws car nuts from all over the world, and showcases a lot of new builds. There is always something new that opens eyes, and gives great inspiration.

This year has been no exception. I have been holding something back from the masses here, and have only been sharing this with a very tight bunch of friends - guys who I can rely upon for solid advice and vision. Don't feel left out....I wanted this to be totally off the radar and low key just on the off chance something went bad.

So, I am going to give a shout out to the guys involved....I'm sure they won't mind - (in alphabetical order) @Budnicks @conv67bdere @Ghostrider 67 @HEMI-ITIS @MarPar @moparnation74 @Richard Cranium @super-bee_ski

These guys have become good friends and I know I can rely upon the information they share - thanks guys.

Second shout out is to a Vendor here - @Johnny Mac and his team at BluePrint Engines in NE. I started talking with Johnny at the start of this year....and asked him to keep it to himself

Thanks Johnny.

Here it is - the engine I chose.....

BluePrint Engines 408CI Stroker Crate Engine | Small Block Chrysler Style | Dressed Longblock with Fuel Injection | Aluminum Heads | Flat Tappet Cam

The type of EFI changed just before I purchased, so I am now the proud owner of a Holley Sniper system. Man it is way better than any carb system I have ever had. Once you get to understand how these work, there is no way you could ever go back. My buddy Cliff is so impressed, he is looking at putting a Sniper in his Ram.

Choosing the 408 was a no-brainer really, as it slots straight into where my 360 was, and the original mounts and brackets, transmission...everything just bolts back up together.

Sure, I made a few mods along the way....but who doesn't?

More about the mods in subsequent posts.

Rest assured....the engine is awesome, and way beyond my expectations.