Yup. 6.1 Hemi convertible

1969 Barracuda 340 Formula S Restoration

- Thread starter RealWing

- Start date

-

Blasted and painted all the bumper brackets, license plate bracket etc and got the front bumper installed.

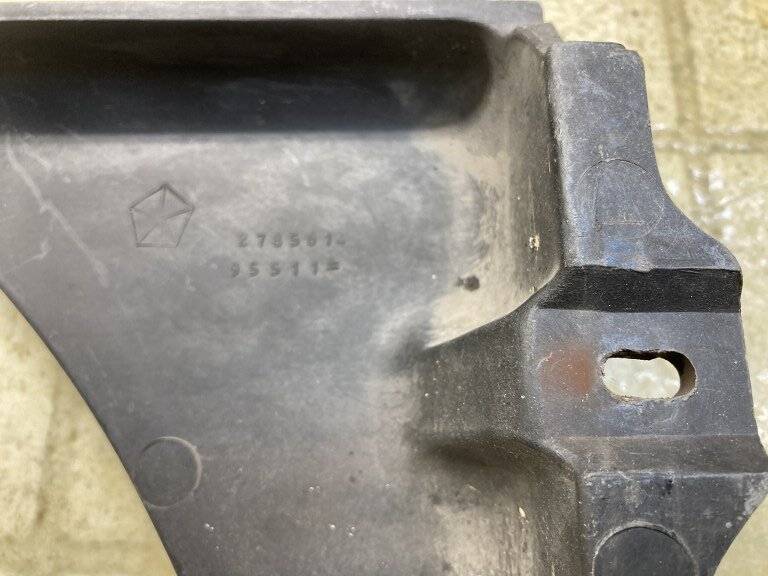

Getting the fan shroud ready for cleanup & painting. 2785614 is the correct p/n for a 340 (also 273, 318 and 383) with AC

Fan shroud done.

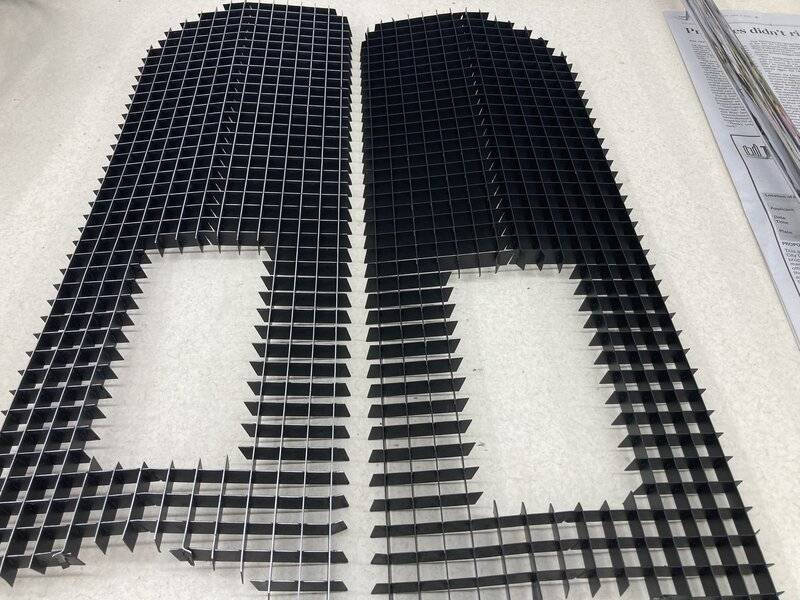

In the process of restoring the front grill assemblies over the last few days. Got one finished and installed. More SEM trim black. After painting the egg crate, I sanded the front to duplicate the original finish.

Grill grates, eyebrows and all are spot on! Nice work!!!

Not surprised at all!

Not surprised at all!

Thanks Gerald. All these finishing details seem to take a huge amount of time!!Grill grates, eyebrows and all are spot on! Nice work!!!

Not surprised at all!

Jim

Ps after recently passing 78 years of “experience”, I relucantly sold my big 2015 BMW K1600 GTL motorcycle

Forward and Back

Powered up the electrical sytem and checked to make sure everything worked. A couple of minor issues but all is good.

Next step was to fill cooling system and then prime the oil system before first start. Added glycol and checked 3 times to make sure no leaks. Had dinner and went back outside and glycol was runnig out from under tha garage door

As near as I can tell it is leaking a bit from the bottom of the water pump gasket. Grrrr.

Everything will have to come off the front of the engine to fix it. No enthusiasm today. Just sat in the backyard watching the world go by!!

Powered up the electrical sytem and checked to make sure everything worked. A couple of minor issues but all is good.

Next step was to fill cooling system and then prime the oil system before first start. Added glycol and checked 3 times to make sure no leaks. Had dinner and went back outside and glycol was runnig out from under tha garage door

As near as I can tell it is leaking a bit from the bottom of the water pump gasket. Grrrr.

Everything will have to come off the front of the engine to fix it. No enthusiasm today. Just sat in the backyard watching the world go by!!

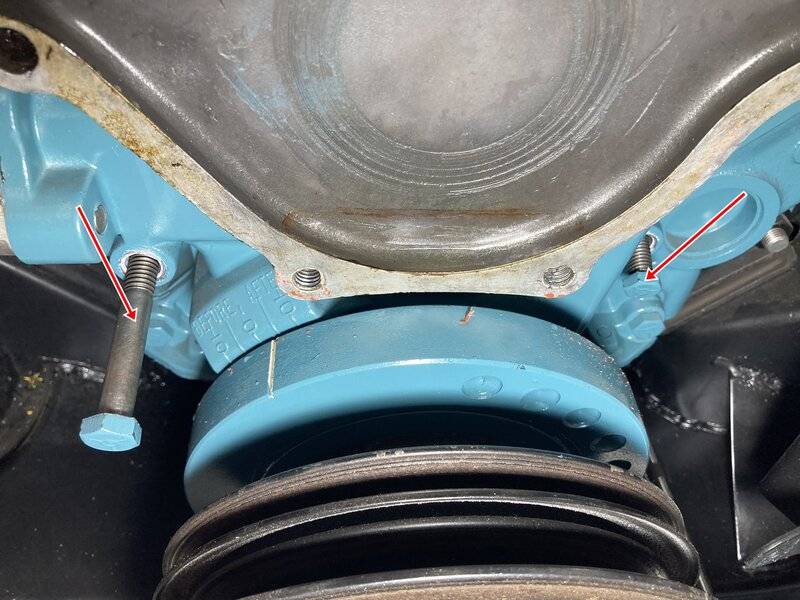

Found the coolant leaks after removing all the parts. The cause was no sealant on the threads of 2 bolts. 2 that go into the water jacket!! The root cause was another case of stupidity!! All the other bolts that required sealant has sealant applied!! I think what happened was that I put the timing cover on first and temporarily bolted it in place without the water pump to ensure it was sealed. To install the WP, I removed all the bolts except these 2, because I didn't have to remove them to install the WP. Forgot to go back and pull them to install sealant!!! Oh well, just a few more hours of work. Also primed the oil system today with the help of my son to rotate the engine while priming.

Jim

Jim

Haven't had time to get back on the Cuda for quite a while due to yard work etc and a bucket list trip to East Africa!!!

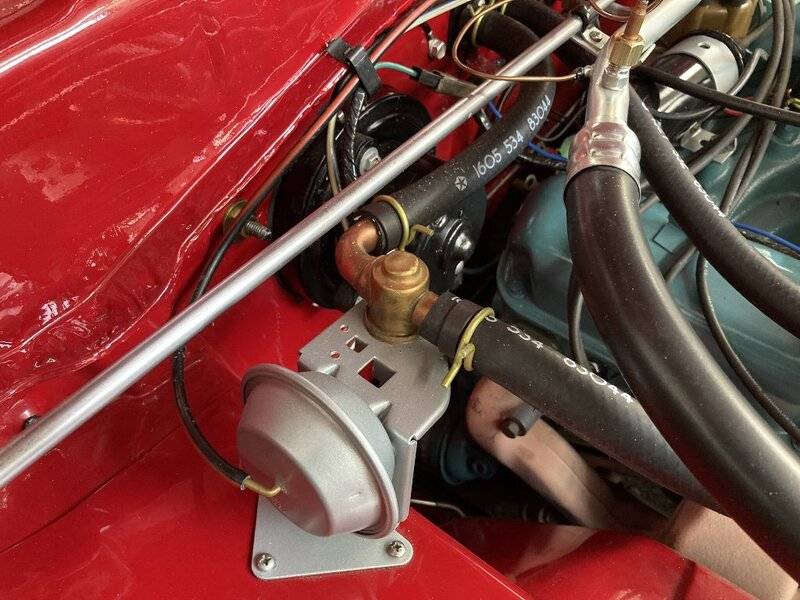

Fired the engine for the first time a couple of weeks ago. Just used a carb because I wanted to be sure it started right up to get the revs up and break in the cam.

Had some small leaks at one tranny fitting at the rad and some at the heater hose connections at the firewall. Did a search to see what others had done about leaks here since I've had problems with these fittings in the past. The consensus seems to be it is a combination of poor quality spring clamps (ie not strong enough) and the repro hoses are thinner than the originals. Thus not enough clamping force.

I saw one neat idea and that was to use some small gear clamps (along with the original style spring clamps) , paint them black and put heat shrink over part of the threaded section. I think it looks pretty good and you can't really tell they are there unless you look close.

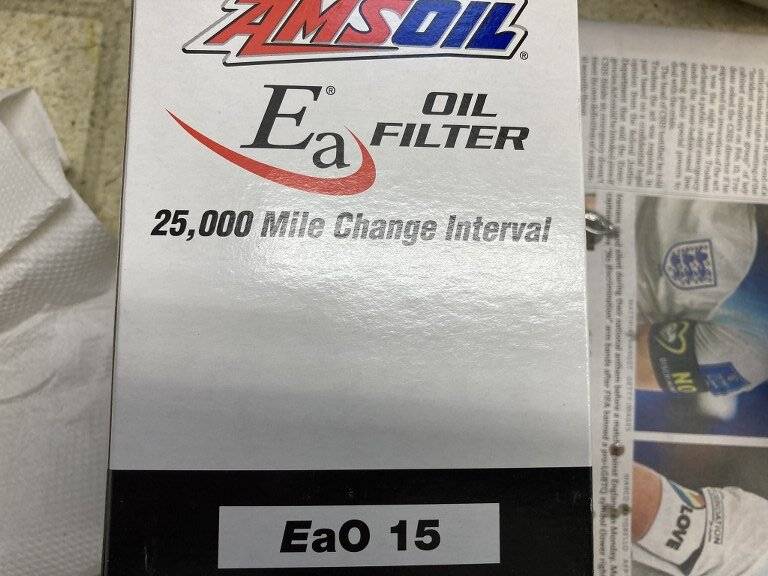

I didn't see any nasty looking bits on the oil filter, so hopefully the cam broke in OK.

Now I can start the installation of the Holley Sniper and Hyperspark CD ignition.

Fired the engine for the first time a couple of weeks ago. Just used a carb because I wanted to be sure it started right up to get the revs up and break in the cam.

Had some small leaks at one tranny fitting at the rad and some at the heater hose connections at the firewall. Did a search to see what others had done about leaks here since I've had problems with these fittings in the past. The consensus seems to be it is a combination of poor quality spring clamps (ie not strong enough) and the repro hoses are thinner than the originals. Thus not enough clamping force.

I saw one neat idea and that was to use some small gear clamps (along with the original style spring clamps) , paint them black and put heat shrink over part of the threaded section. I think it looks pretty good and you can't really tell they are there unless you look close.

I didn't see any nasty looking bits on the oil filter, so hopefully the cam broke in OK.

Now I can start the installation of the Holley Sniper and Hyperspark CD ignition.

Super-Cuda

MOPAR .. Move Over, Plymouth Approaching Rapidly!

Haven't had time to get back on the Cuda for quite a while due to yard work etc and a bucket list trip to East Africa!!!

Fired the engine for the first time a couple of weeks ago. Just used a carb because I wanted to be sure it started right up to get the revs up and break in the cam.

Had some small leaks at one tranny fitting at the rad and some at the heater hose connections at the firewall. Did a search to see what others had done about leaks here since I've had problems with these fittings in the past. The consensus seems to be it is a combination of poor quality spring clamps (ie not strong enough) and the repro hoses are thinner than the originals. Thus not enough clamping force.

I saw one neat idea and that was to use some small gear clamps (along with the original style spring clamps) , paint them black and put heat shrink over part of the threaded section. I think it looks pretty good and you can't really tell they are there unless you look close.

I didn't see any nasty looking bits on the oil filter, so hopefully the cam broke in OK.

Now I can start the installation of the Holley Sniper and Hyperspark CD ignition.

View attachment 1716014792

View attachment 1716014793

View attachment 1716014794

View attachment 1716014795

View attachment 1716014796

Hi Jim,

No big deal, trials and tribulations of the restoration process we all go through!

Love the attention to detail.

Here's a suggestion for your hose clamp problem.

Use these , turn them upside down and put the corbin clamp next to it for asthetics. You will need a special tool to install them due to the clamping pressure.

These won't leak!

Back at the Cuda again!!!

A couple of things I has seen mentioned on the Holley Sniper forum was low voltage.

1. Low voltage on the +12V Key on feed to the sniper when cranking. Apparently anything below 11 volts causes problems on starting. I connected the IGN1 feed to the sniper feed and then cranked the engine. Sure enough, the voltage was below 11V. (The IGN1 also connects to the voltage regulator which pulls the voltage down)

I made a wiring mod to add a relay to ensure I had a >12V supply to the sniper as well as the voltage regulator.

2. The forum also mentioned low voltage conditions when idling with headlights and heater on etc. The stock alternator does not put out sufficient voltage under high load and idle speeds. I've now swapped out the original alternator for a Powermaster 7018. Powermaster 7018 Powermaster Retro Alternators | Summit Racing Hopefully that will solve this problem.

A couple of things I has seen mentioned on the Holley Sniper forum was low voltage.

1. Low voltage on the +12V Key on feed to the sniper when cranking. Apparently anything below 11 volts causes problems on starting. I connected the IGN1 feed to the sniper feed and then cranked the engine. Sure enough, the voltage was below 11V. (The IGN1 also connects to the voltage regulator which pulls the voltage down)

I made a wiring mod to add a relay to ensure I had a >12V supply to the sniper as well as the voltage regulator.

2. The forum also mentioned low voltage conditions when idling with headlights and heater on etc. The stock alternator does not put out sufficient voltage under high load and idle speeds. I've now swapped out the original alternator for a Powermaster 7018. Powermaster 7018 Powermaster Retro Alternators | Summit Racing Hopefully that will solve this problem.

Tim Murphy

Well-Known Member

I did this two years ago and added the relay kit to reduce voltage on the headlamps. My 340 Barracuda instantly came to life with this powermaster upgrade running the Sniper. Great upgrade for your car.

I've installed the headlight relay kit as well as well as a larger wire from alternator direct to the starter relay(Crackedback) Ammeter bypass also done.

Tim Murphy

Well-Known Member

Same! We are in lockstep here and you’ll notice a difference right away. Going to do the same for my 67 here this summer

Nice condition on your engine compartmentBack at the Cuda again!!!

A couple of things I has seen mentioned on the Holley Sniper forum was low voltage.

1. Low voltage on the +12V Key on feed to the sniper when cranking. Apparently anything below 11 volts causes problems on starting. I connected the IGN1 feed to the sniper feed and then cranked the engine. Sure enough, the voltage was below 11V. (The IGN1 also connects to the voltage regulator which pulls the voltage down)

I made a wiring mod to add a relay to ensure I had a >12V supply to the sniper as well as the voltage regulator.

2. The forum also mentioned low voltage conditions when idling with headlights and heater on etc. The stock alternator does not put out sufficient voltage under high load and idle speeds. I've now swapped out the original alternator for a Powermaster 7018. Powermaster 7018 Powermaster Retro Alternators | Summit Racing Hopefully that will solve this problem.

View attachment 1716058122

View attachment 1716058123

moparmat2000

Well-Known Member

Holley now sells LED headlamps that look like old sealed beams. You can get them with bright white, or the older yellowish glow white light. If using these which have a lot lower amp draw, couldent you get away from having to do headlight relays? BTW I'm thoroughly enjoying watching your build thread.

If you go with LED headlights, I don't think you would need relays - BUT I havent see the current draw with Holley's lights.

scatpackbee

Well-Known Member

They are not cheap…

Last edited:

moparmat2000

Well-Known Member

Looking at your front reflector bezels, mine dont look like that, with a deep inset at the top. But then again my 69 notch started as a basket case missing almost everything. I picked up 2 sets of 69 dart front fender bezels to use. Figured those were correct. A few years back I found a 69 fury in the boneyard, it had one deep bezel, and one not deep bezel on it. Looked like a factory assembly line screw up that nobody noticed since they were original to the car. I sold those since they didnt match. Kinda wondering if either one would have been correct to use. It appears that your bezel angles the reflector more straight. My dart bezels would angle the reflector more down than straight. May have been a thing needed for it to pass DOT regs with the fender curvature? A different bezel.Blasted and painted all the bumper brackets, license plate bracket etc and got the front bumper installed.

View attachment 1715939320

View attachment 1715939321

Holley now sells LED headlamps that look like old sealed beams. You can get them with bright white, or the older yellowish glow white light. If using these which have a lot lower amp draw, couldent you get away from having to do headlight relays? BTW I'm thoroughly enjoying watching your build thread.

the deep insert ones are correct for the front so that the reflector is more vertical. Plus the part number is 2930751 front and 2930 757 for the rear. Interesting about the Fury. Just goes to show anything is possible from Chrysler back in the days!!!!Looking at your front reflector bezels, mine dont look like that, with a deep inset at the top. But then again my 69 notch started as a basket case missing almost everything. I picked up 2 sets of 69 dart front fender bezels to use. Figured those were correct. A few years back I found a 69 fury in the boneyard, it had one deep bezel, and one not deep bezel on it. Looked like a factory assembly line screw up that nobody noticed since they were original to the car. I sold those since they didnt match. Kinda wondering if either one would have been correct to use. It appears that your bezel angles the reflector more straight. My dart bezels would angle the reflector more down than straight. May have been a thing needed for it to pass DOT regs with the fender curvature? A different bezel.

moparmat2000

Well-Known Member

I will probably use what I have since they are more common, and the deep offset ones seem to be harder to find. That is unless you have a spare set to sell me lolthe deep insert ones are correct for the front so that the reflector is more vertical. Plus the part number is 2930751 front and 2930 757 for the rear. Interesting about the Fury. Just goes to show anything is possible from Chrysler back in the days!!!!

Sorry. No spares!I will probably use what I have since they are more common, and the deep offset ones seem to be harder to find. That is unless you have a spare set to sell me lol

With the upgraded alternator, I wondered if the electronic voltage regulator would be able to handle the increased field current. Decided to measure the field current on the upgraded one and the restored original.

Simply connected full battery voltage to the field (engine not running!!) which would be full field forcing.

Stock 3.8-4.0 amps at 12.4 VDC

HO 4.6- 4.7 amps at 12.6VDC

About 1 amp difference at full output. Hopefully will be OK

Simply connected full battery voltage to the field (engine not running!!) which would be full field forcing.

Stock 3.8-4.0 amps at 12.4 VDC

HO 4.6- 4.7 amps at 12.6VDC

About 1 amp difference at full output. Hopefully will be OK

Some more electrical info.

I installed the relay on the IGN1 wire to fed the sniper and voltage regulator. I then did a cranking test with 2 different batteries to see what the voltage was on the sniper 12V feed.

Test #1 was with my gutted repro battery with an Odyssey PC 925 battery inside. It cranks the engine just fine, but Voltage was only 10.1 Volts - too low

Test # 2 was an Exide AGM MX24 Group 24 battery. Voltage was 12.1 V which is OK. I'm going to add a battery topper to make it look somewhat stock.

I installed the relay on the IGN1 wire to fed the sniper and voltage regulator. I then did a cranking test with 2 different batteries to see what the voltage was on the sniper 12V feed.

Test #1 was with my gutted repro battery with an Odyssey PC 925 battery inside. It cranks the engine just fine, but Voltage was only 10.1 Volts - too low

Test # 2 was an Exide AGM MX24 Group 24 battery. Voltage was 12.1 V which is OK. I'm going to add a battery topper to make it look somewhat stock.

-