Hemiorangeswinger

Dodge Material

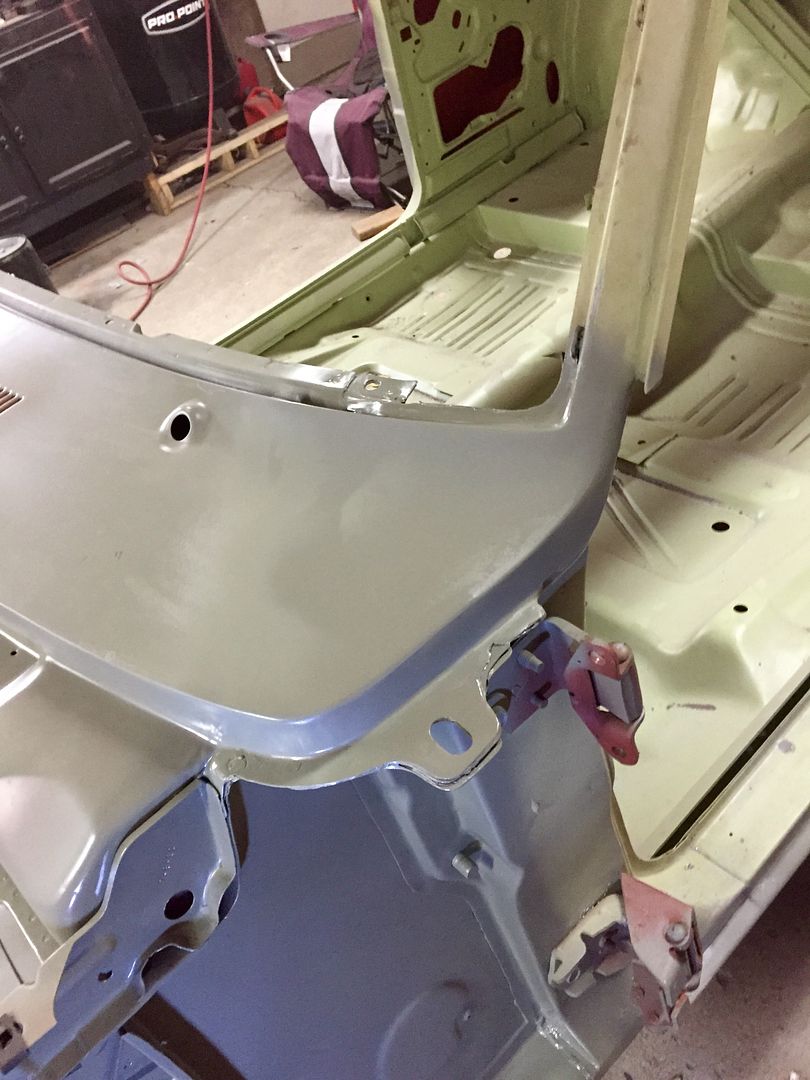

Outstanding job on the cowl! Keep those progress pics coming!

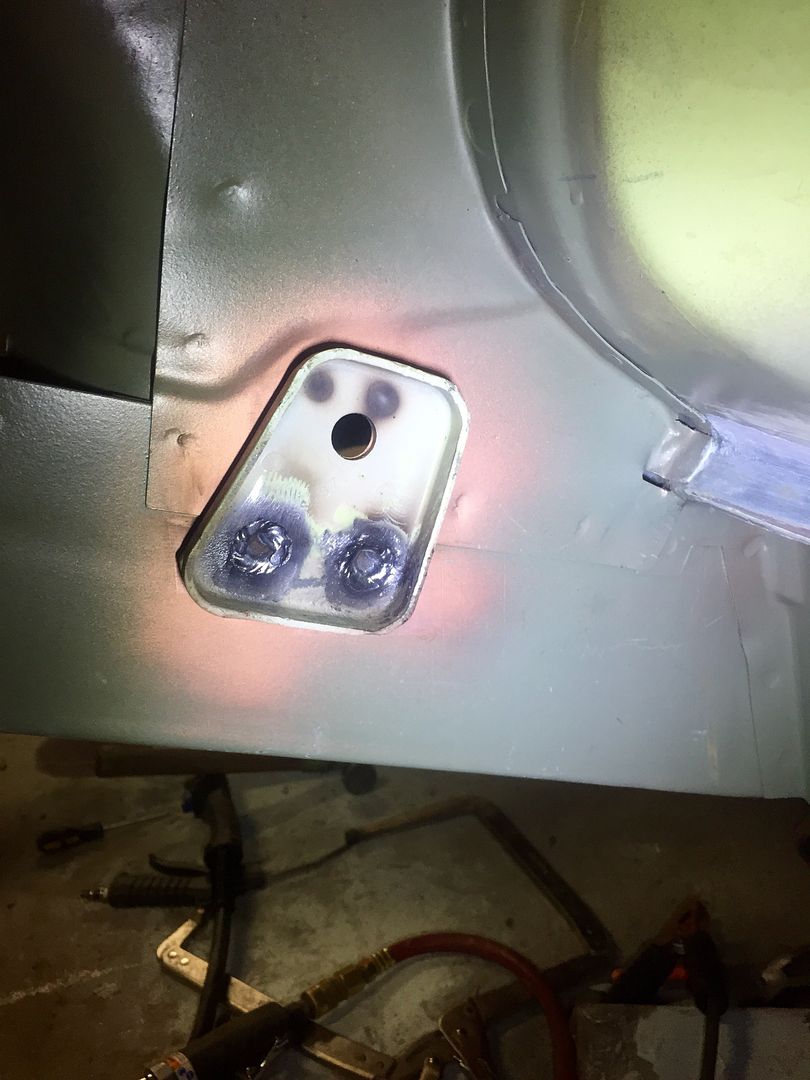

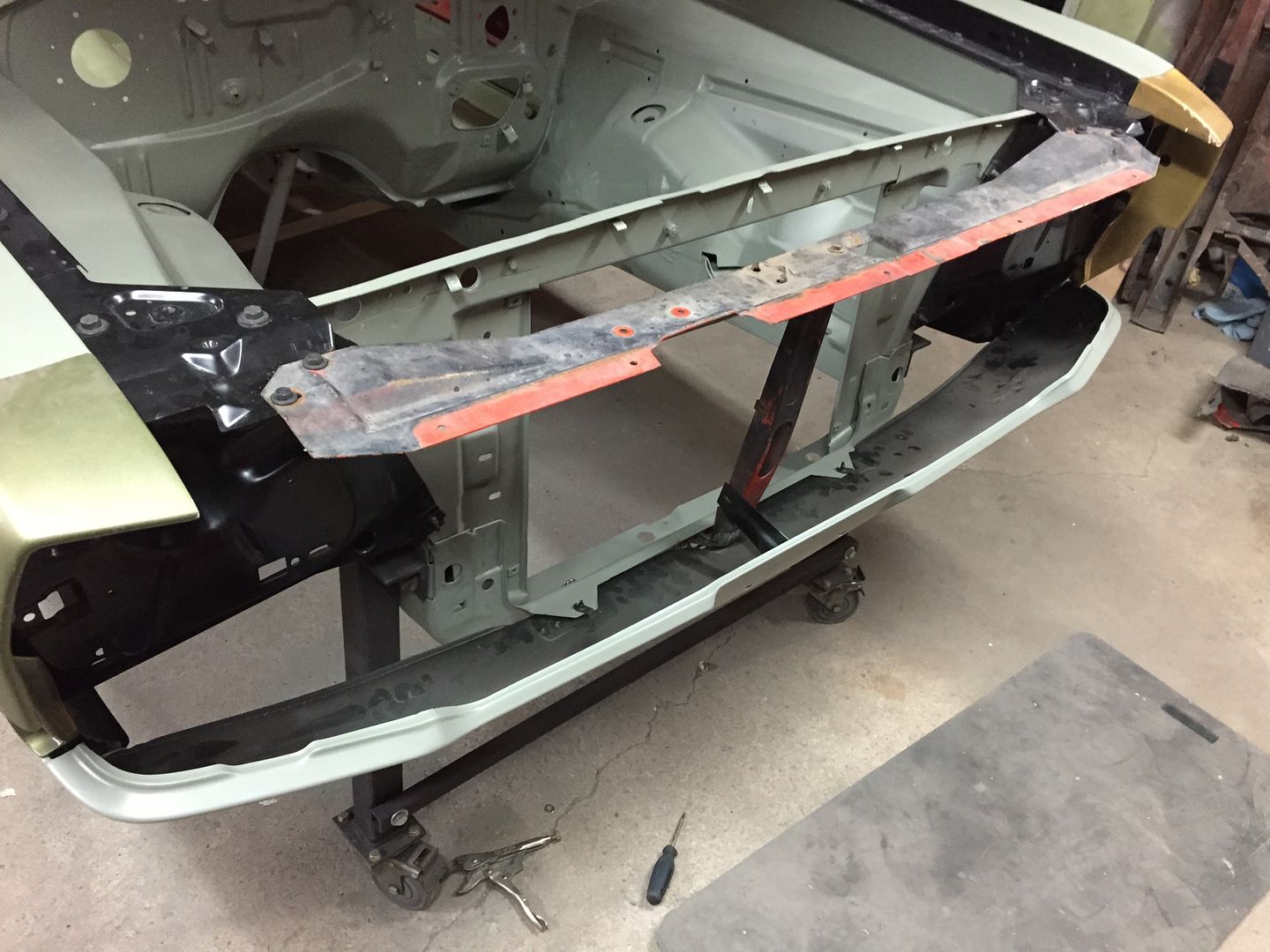

Thanks!! I got my K frame back from the dippers and epoxied it. I took some gun wash and a red scotch-brite and scuffed it up to give the epoxy something to bite to and clean the flash rust off. Having parts dipped is the way to go.. The parts come out spotless!! I will beat some of the dents out of the bottom and put a coat of semi gloss paint on it when I get a chance. The factory welds on the K frame are terrible! They must be strong tho because they haven't broke after 40+ years.

I read somewhere that the washer welded on the front meant it was a 340 K frame and had additinal welds and extra bracing around the lower control arm mounts..this one has the extra half moon brace around the lower control arm mount.