I think I'm reading this right and I think this teen needs bored out.

Last edited:

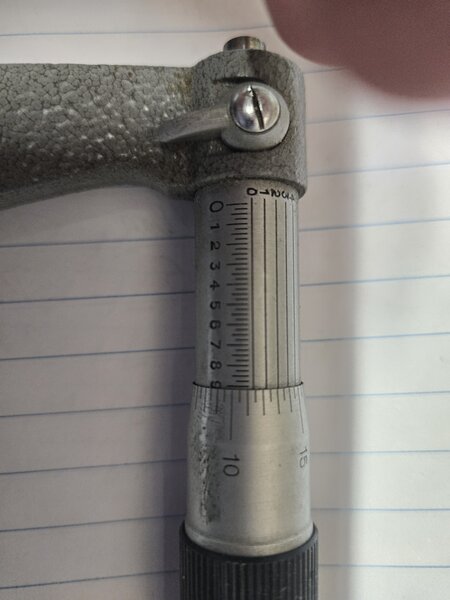

Snap gauge and a mic I suspect.Are you measuring the piston? You should be measuring the bore.

Shamefully, I have a bore gauge, used it once and forgot how to use it.If you are measuring correctly, .0013 would not need to be bored. Unfortunately I feel the is an error in the equipment or technique. You should not be able to feel .0013". A hot shot Engineer should have her own dial bore gage and setting rings ;-)

It has been my understanding and experience the average human hand can feel 0.001"You should not be able to feel .0013"

Fine as frog's hair?It has been my understanding and experience the average human hand can feel 0.001"

.010 in my experience. I could read a scale to .010. but a dial bore gage should be good to .0001" and not everyone can do that. A man has to know his limitations.It has been my understanding and experience the average human hand can feel 0.001"

I thought of that, but without seeing the whole tool.....lolSnap gauge and a mic I suspect.

There you go!

That would certainly change things if it is 3.910Help me out. Where are you coming up with 3.906"? I thought the standard bore for the 318 was 3.910. Then, the pistons are slightly under size to give the clearance.