CordobaDart

318 SLANTMAN

I was not planning on building this engine but am commited now. While visiting a cousin who has a few Mopars himself, he gave me a crank and pistons that was not going to get used anymore. A 3.58 eagle cast crank that was used in a 340 in good shape. Then I got ideas in my head...

A 70 318 has been lurking around my storage of parts for 8 years had pitting and wear in the bores. I would like to do a fun street build. I have a few 360's laying around in the garage that are good low mileage ones, but figured, why not use this otherwise not going to be used 318 and free 3.58" crank? The casting of this crank does show imperfections(bubbles in the counterweights) but was run successfully before someone yanked it for a 4" stroke crank.

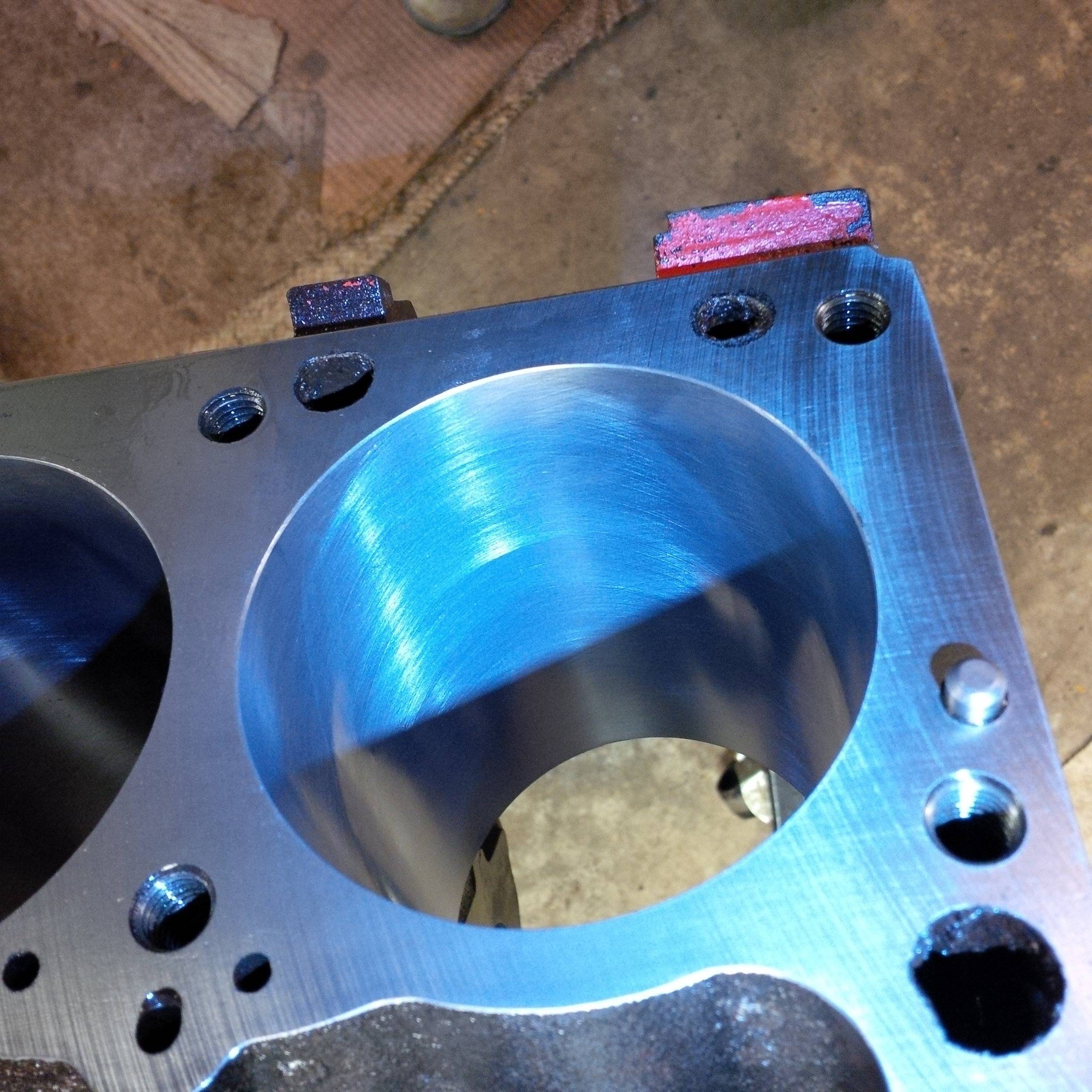

Got the block zero decked/bored to a set of kb107 standard bore pistons. I am thinking of doing a partial fill of hard block just up to the top of the frost plugs but am on the fence with that. I will update this as I slowely work on it and collect parts. The goal is to have the rotating assembly in by the end of summer. Heads/cam will come later (probably over winter). I was going to run the factory 318 full float rods but they need to be resized and the crank was balanced to lighter scat rods and some 4.070 kb107's when it was in a 340, so I do not want to pay for mallory metal, so I will get different rods. I know it is a gamble of a build, just thought I would share, maybe in the future I can use this as a what NOT to do thread. Haha

A 70 318 has been lurking around my storage of parts for 8 years had pitting and wear in the bores. I would like to do a fun street build. I have a few 360's laying around in the garage that are good low mileage ones, but figured, why not use this otherwise not going to be used 318 and free 3.58" crank? The casting of this crank does show imperfections(bubbles in the counterweights) but was run successfully before someone yanked it for a 4" stroke crank.

Got the block zero decked/bored to a set of kb107 standard bore pistons. I am thinking of doing a partial fill of hard block just up to the top of the frost plugs but am on the fence with that. I will update this as I slowely work on it and collect parts. The goal is to have the rotating assembly in by the end of summer. Heads/cam will come later (probably over winter). I was going to run the factory 318 full float rods but they need to be resized and the crank was balanced to lighter scat rods and some 4.070 kb107's when it was in a 340, so I do not want to pay for mallory metal, so I will get different rods. I know it is a gamble of a build, just thought I would share, maybe in the future I can use this as a what NOT to do thread. Haha