nm9stheham

Well-Known Member

Just fixed that.... you have to "Leave" a conversation.... you can't "delete" it LOL

Caps 2/6 did not have extenders for tray. A quick look at Hughes, and I can get an ARP entire set for over $100. Why so freaking much? Any other options? Is finding just the 2 cap bolts with extenders difficult, and if i do,

2/6 caps? 6 caps?

Are you talking about the four bolts that are extended for the windage tray that go on the #2 and #4main caps?

Yes. Looks like I need to buy a whole kit, because of the 4 missing bolts. I'm just surprised how much it costs.

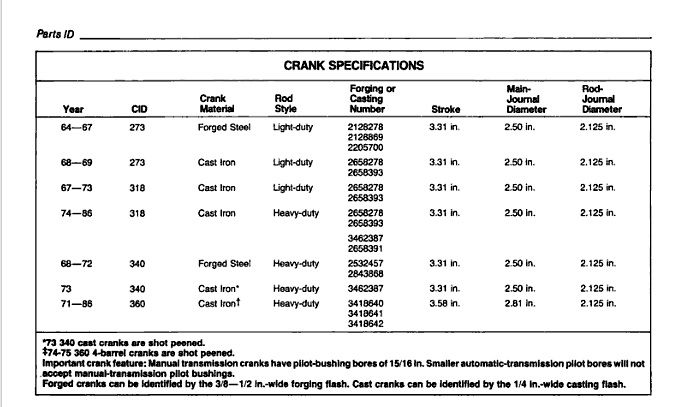

I guess we are in trouble then.. that is what my son and I used in our 340. Edlebrock heads and all! Remember, we took over 250 grams of bobweight off of the crank pins versus a stock 273/318, and the OP is doing the same.The early 273s had spindly little rods in them. Ima thinking the crank that goes with those rods would not be the one to use. I have one of those cranks here, as well as examples of at least one of every other factory crank. That 273 crank looks pretty wimpy next to a forged teener crank.

If you need a crank anyway and you actually want to keep the Rs down, would your project be a prime candidate to become a stroker?

I guess we are in trouble then.. that is what my son and I used in our 340. Edlebrock heads and all! Remember, we took over 250 grams of bobweight off of the crank pins versus a stock 273/318, and the OP is doing the same.

Other factors:

- The 273/318 light rods only weigh 5-6% less than 340 rods, so looks can be deceiving for those and the cranks.All my 68 to 72 or so teener rods look identical to 340 rods, same casting numbers and all. And they all in turn look the same as my 360 rods which are less the upper bushings. The 273 rods I have are from a 65 and they look nothing at all like the other bunch; spindly,sickly-looking in comparison.In my 367, I installed the bushed teener rods, with new bushings. I never weighed any of these. So I cannot say how much less the 273 rods might be.

- Crank strength is also in the materials' strength, not just the quanitity.Understood

- And since only so much torque can be put on the crank with an A-body before the wheels spin, that is a help too; it is not a truck at 10 tons with 3-4 more times traction and lugging up a long hill. Yeahbut can it withstand 18 years of 7200rpm blasts, with 295s or sometimes 325s, with neutral drops with a CFII trying to split the A833 wide open? I mean my 367 has ripped teeth off 5.38s and 3.91s. It has shredded U-joints and clutch discs, and spit out damper springs on several occasions. It has ripped teeth off the input of one A833 OD box and all the teeth of the cluster at the od location,twice. I wasn't interested in saving weight when I put that 367 together, except to balance those lightweight hypers, and I put the balance in the flywheel also for that reason; namely, I didn't have the smarts to try and fool around with the internals.

I promise I'll let you know as soon as we snap that 273 crank. (Cue the 'Jeopardy waiting music'... LOL)

You did know that early 273's had forged cranks.LOL.. .no spanking! No, I'm just going on my faith in a lot of Mopar guys who have gone before me. (Plus some common sense engineering on the lighter weights.) In reality, I'm just taking the general 'word' for it that the SBM cast cranks are good to over 400 HP.

I never saw any info saying that there was a difference in the different cast cranks' capabilities, but it may never have a come up. I kinda assumed the 273/318's are all the same early or late, but then again, the later 318 cranks went with heavier rods so I can be all wet on that.

If you have an early 273 cast crank and late 318 cast crank side by side and had some pix, THAT I would be interested in seeing. I just don't have that big stash of SBM parts around like a lot of guys.

Showtime!I bet I can still fit my belly button in the pic somehow.